Target with metal glass coating and composite material prepared from target

A technology of metallic glass and composite materials, which is applied in the direction of metal material coating process, sputtering plating, ion implantation plating, etc., can solve problems such as difficult mass production and application, difficult processing and production, and inability to master metallic glass coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

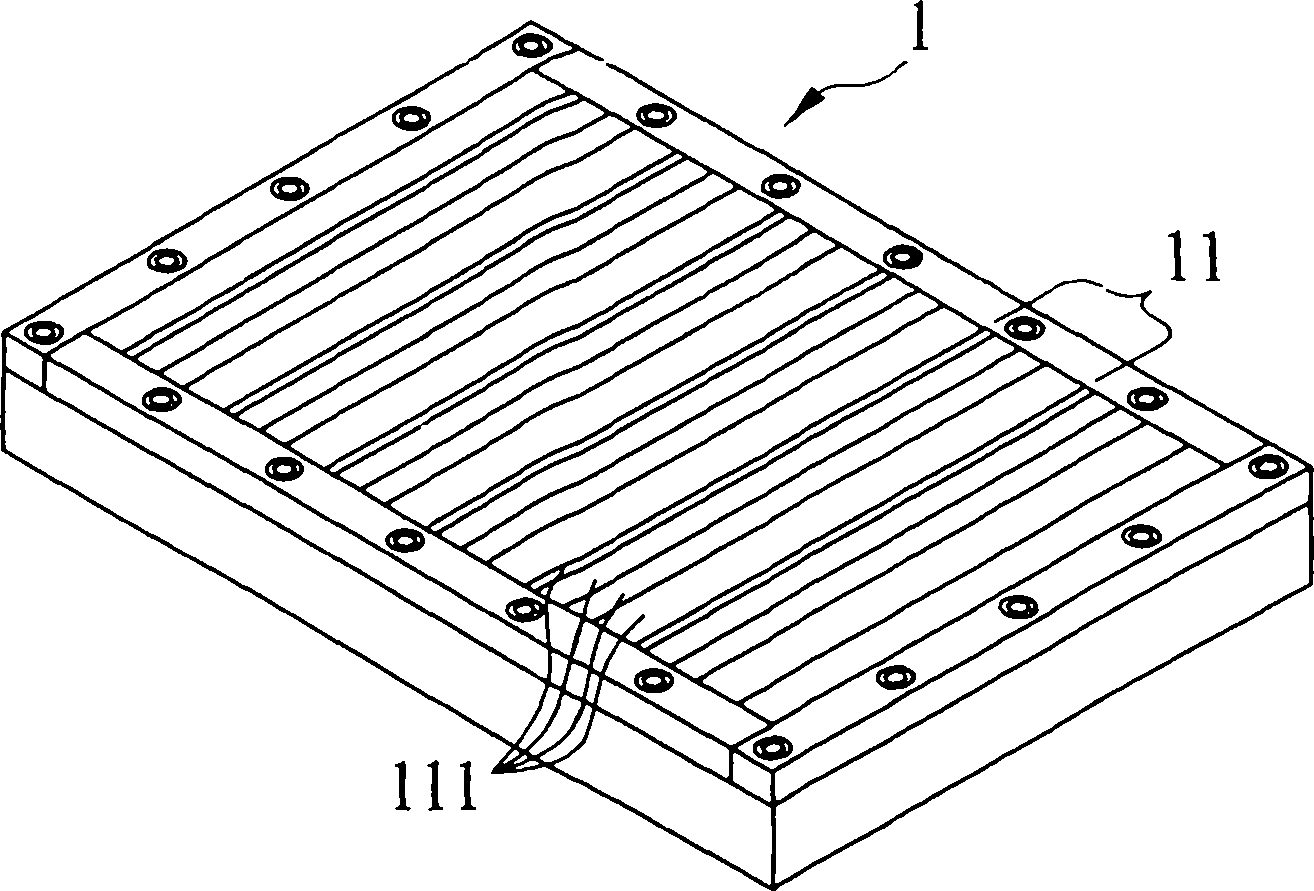

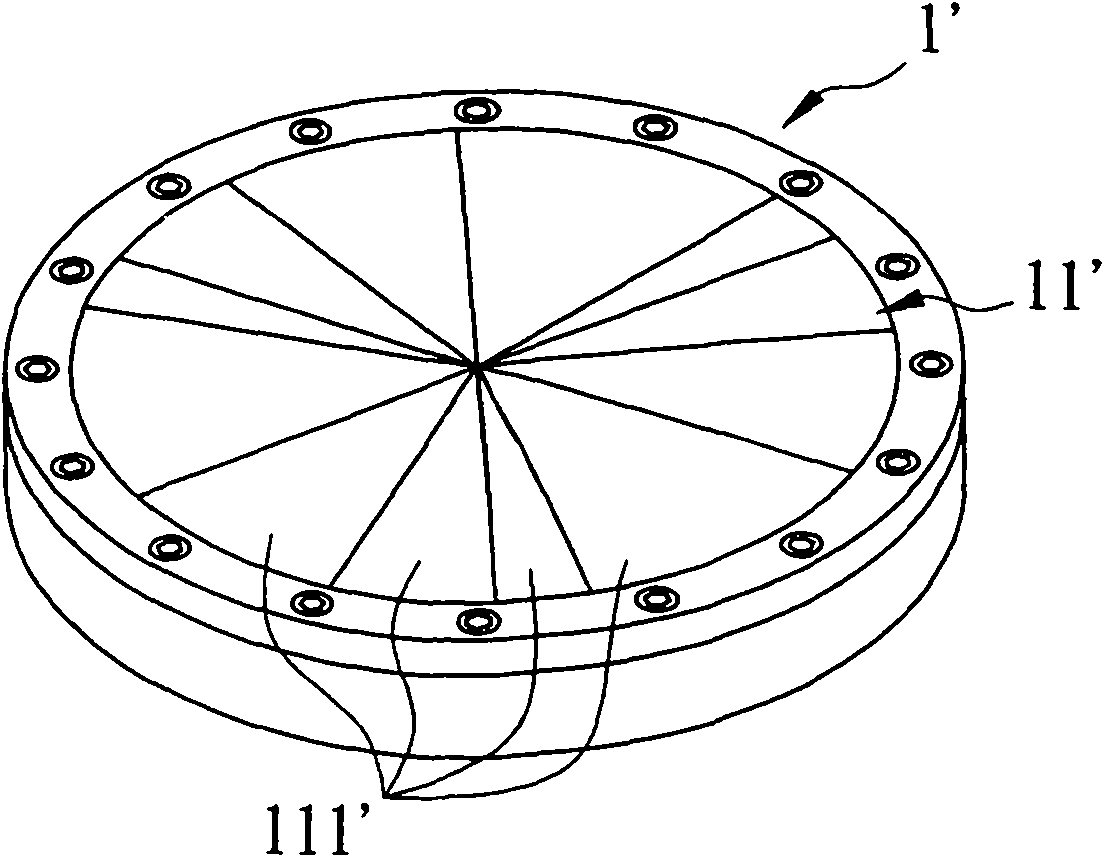

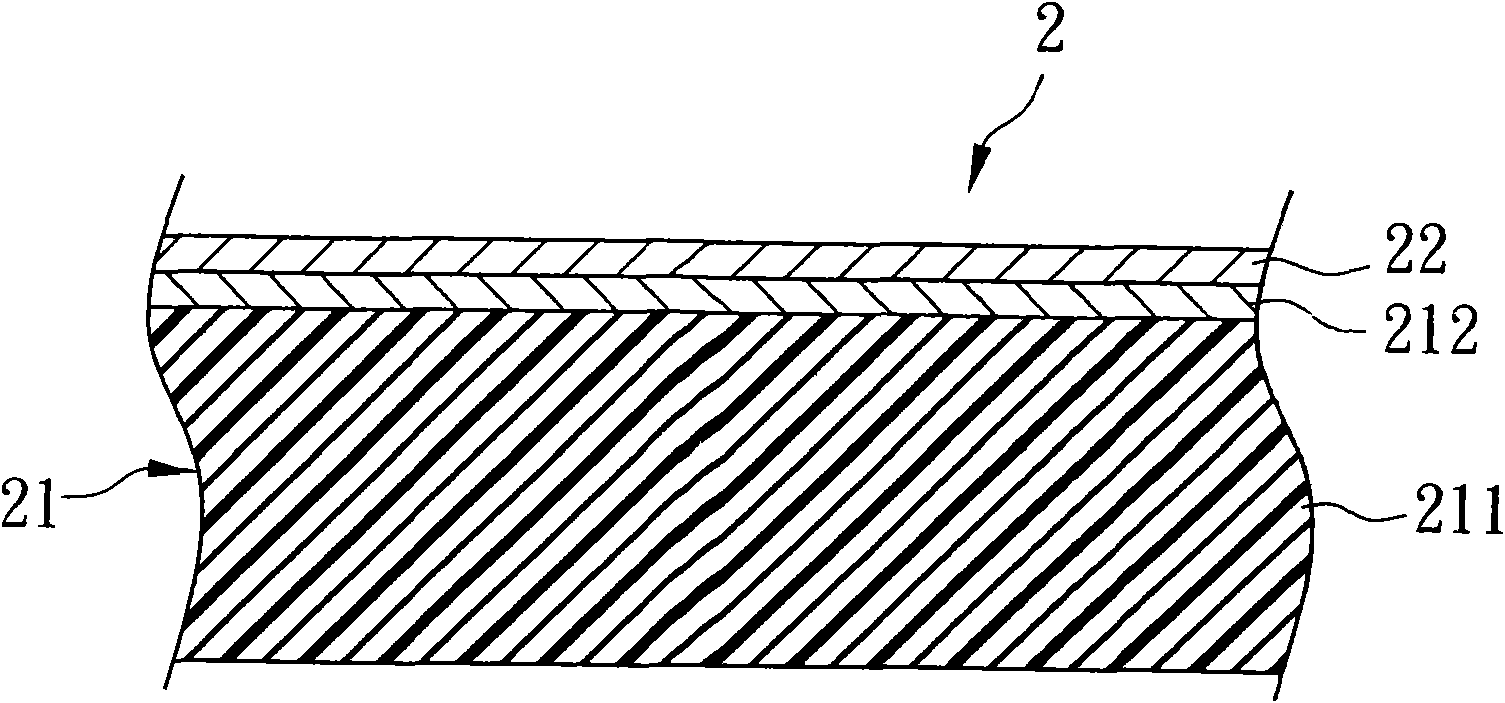

[0026] refer to figure 1 , figure 2 , image 3 ,Such as figure 1 , figure 2 Shown is a first and second preferred embodiment of a target material 1 for forming a metallic glass coating film of the present invention, both of which are suitable for physical vapor deposition process (such as dry plasma vapor deposition), and on the substrate 21 Form metallic glass coating film 22, become as image 3 The shown composite material 2 with metallic glass coating 22 can be widely used in aspects such as metal bipolar plates of fuel cells, surgical knives for medical use, and shell parts of 3C products.

[0027] see first image 3 , the composite material 2 includes a substrate 21 and a metallic glass coating 22 formed by using the target 1 disclosed in the first or second preferred embodiment.

[0028]The substrate 21 has a body 211, and a film body 212 formed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com