Smoke-removing muffler for agricultural automobile

A technology for agricultural vehicles and mufflers, applied in the field of vehicle engineering, can solve problems such as environmental pollution, and achieve the effects of low cost, compact structure and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

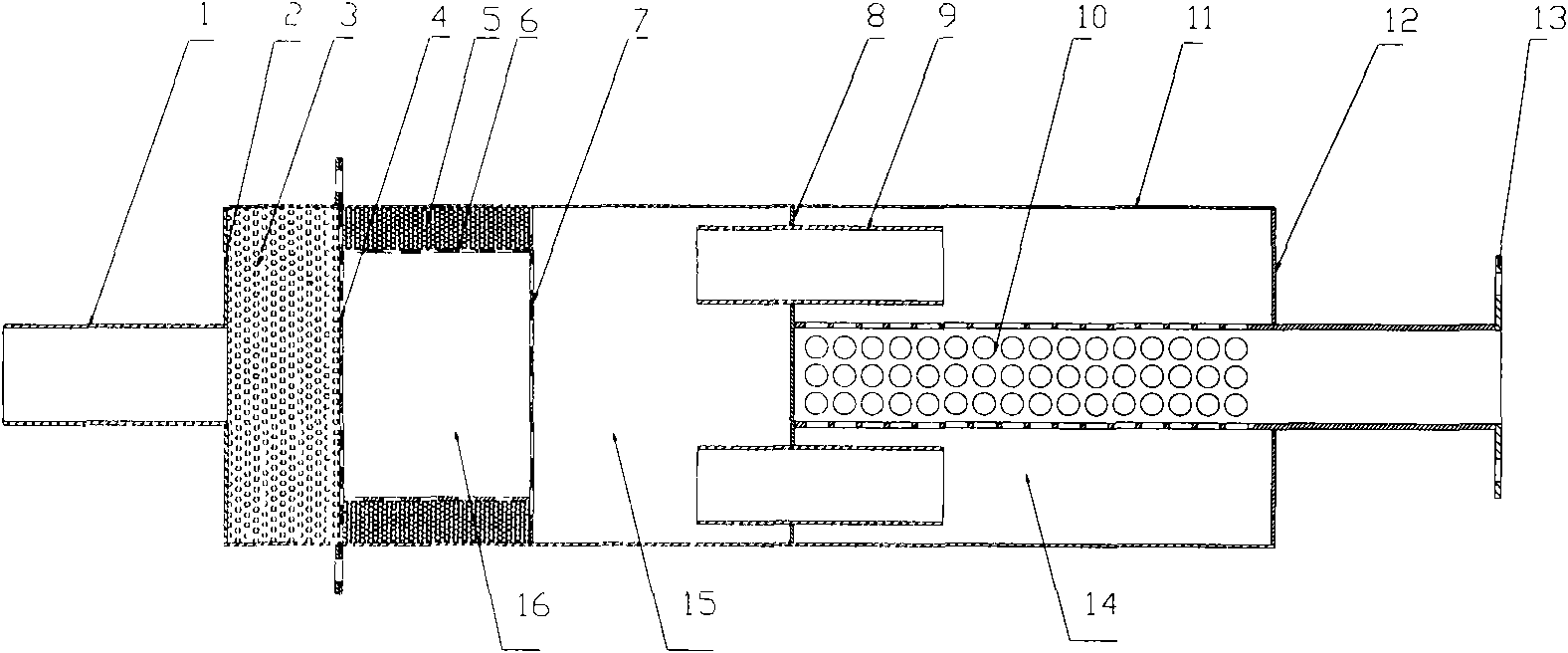

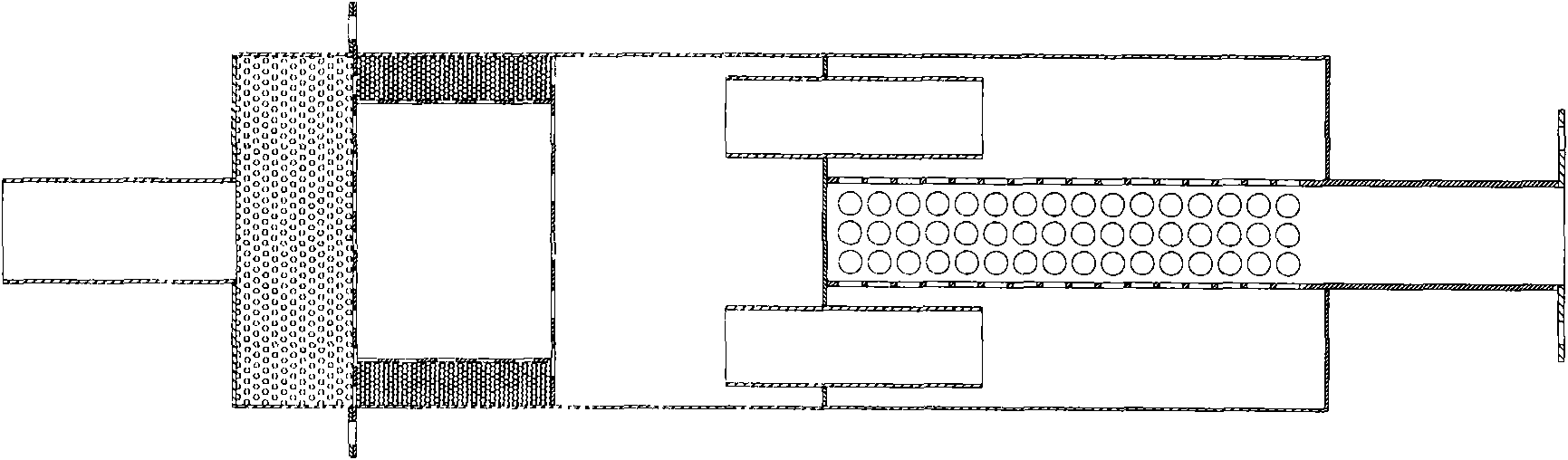

[0009] In the accompanying drawing, the noise generated by the exhaust gas enters from the perforated tube 10 on the right side along with the air flow, expands and eliminates noise in the first expansion chamber 14 on the right, then enters the two inner insertion tubes 9 to shrink and eliminate noise, and then enters through the inner insertion tube 9 The second expansion chamber 15 expands and eliminates noise again, and then the airflow passes through the micro-perforated plate 7 to shrink and eliminate noise, and then enters the third expansion chamber 16, expands and eliminates noise again, and the third expansion chamber 16 is absorbed by the sound-absorbing material 5 Part of the noise, through the micro-perforated plate 4, the airflow shrinks and silences, enters the smoke cleaning (smoke filter) room at the rear, intercepts the soot particles through the smoke cleaning (smoke filter) material 3, and finally passes through the exhaust tail pipe 1 row of the smoke cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com