Fluorescence radiation lamp tube

A lamp and fluorescent technology, applied in the direction of discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve the problems of increasing the complexity and processing difficulty of bulbs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

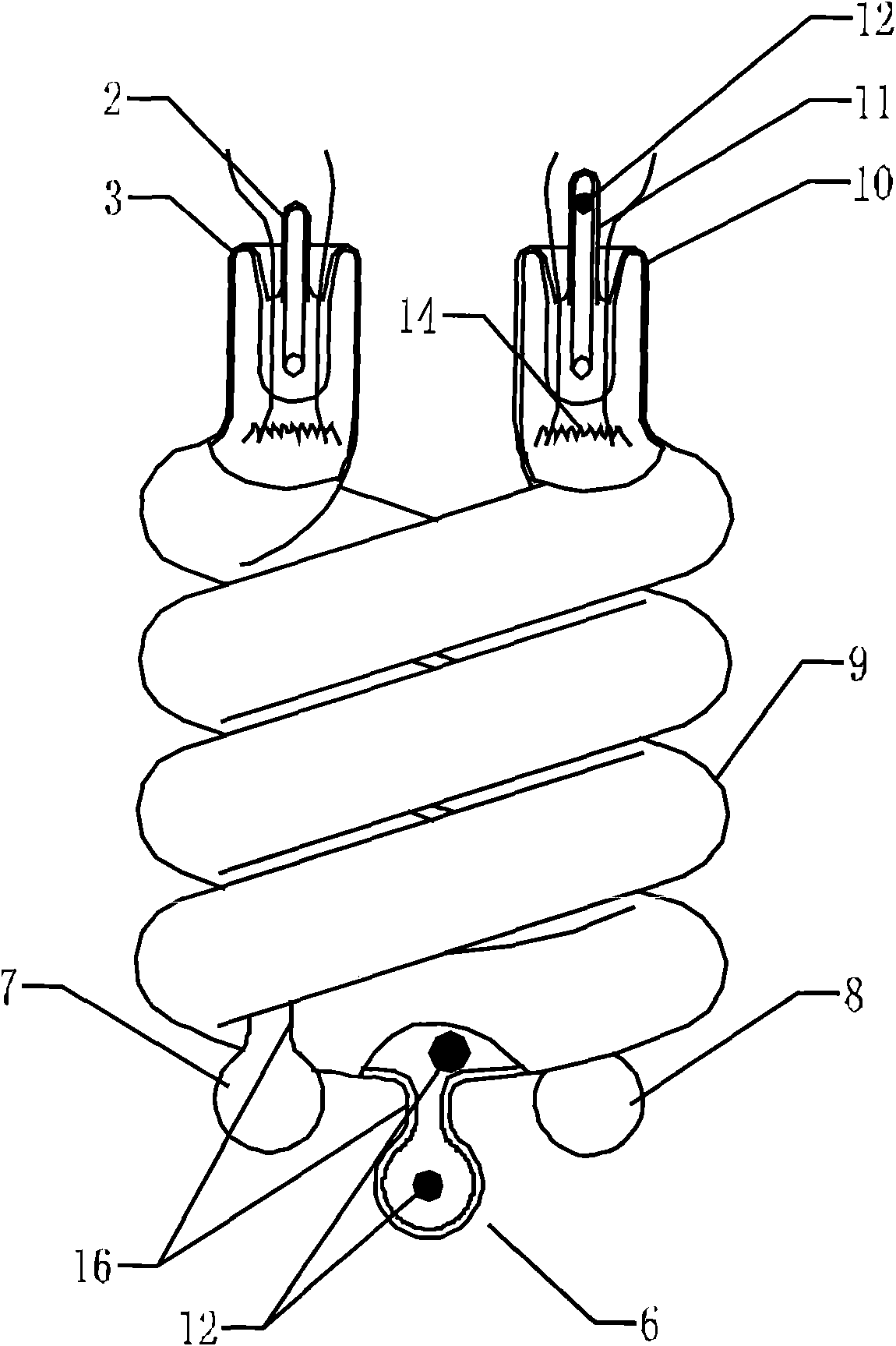

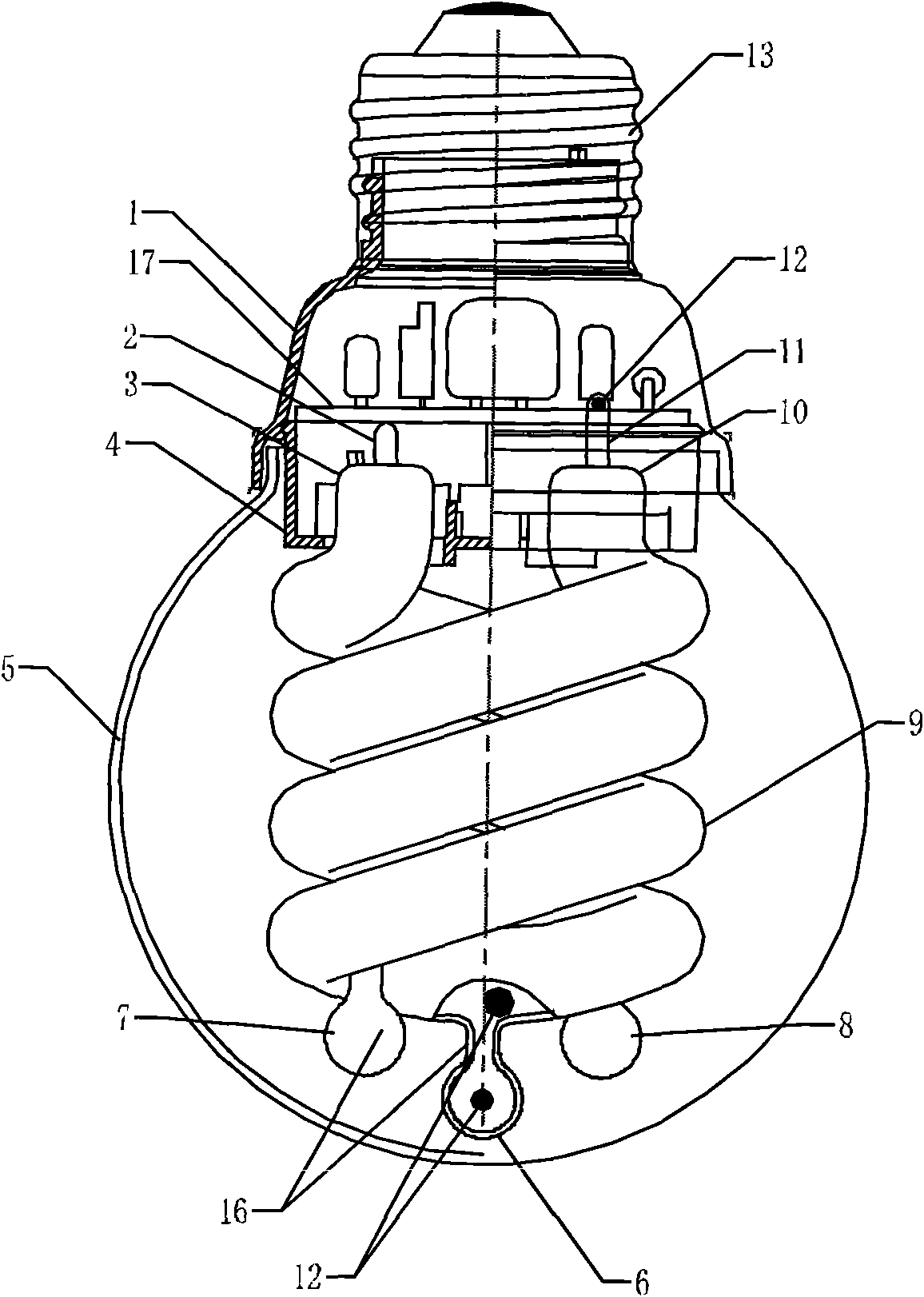

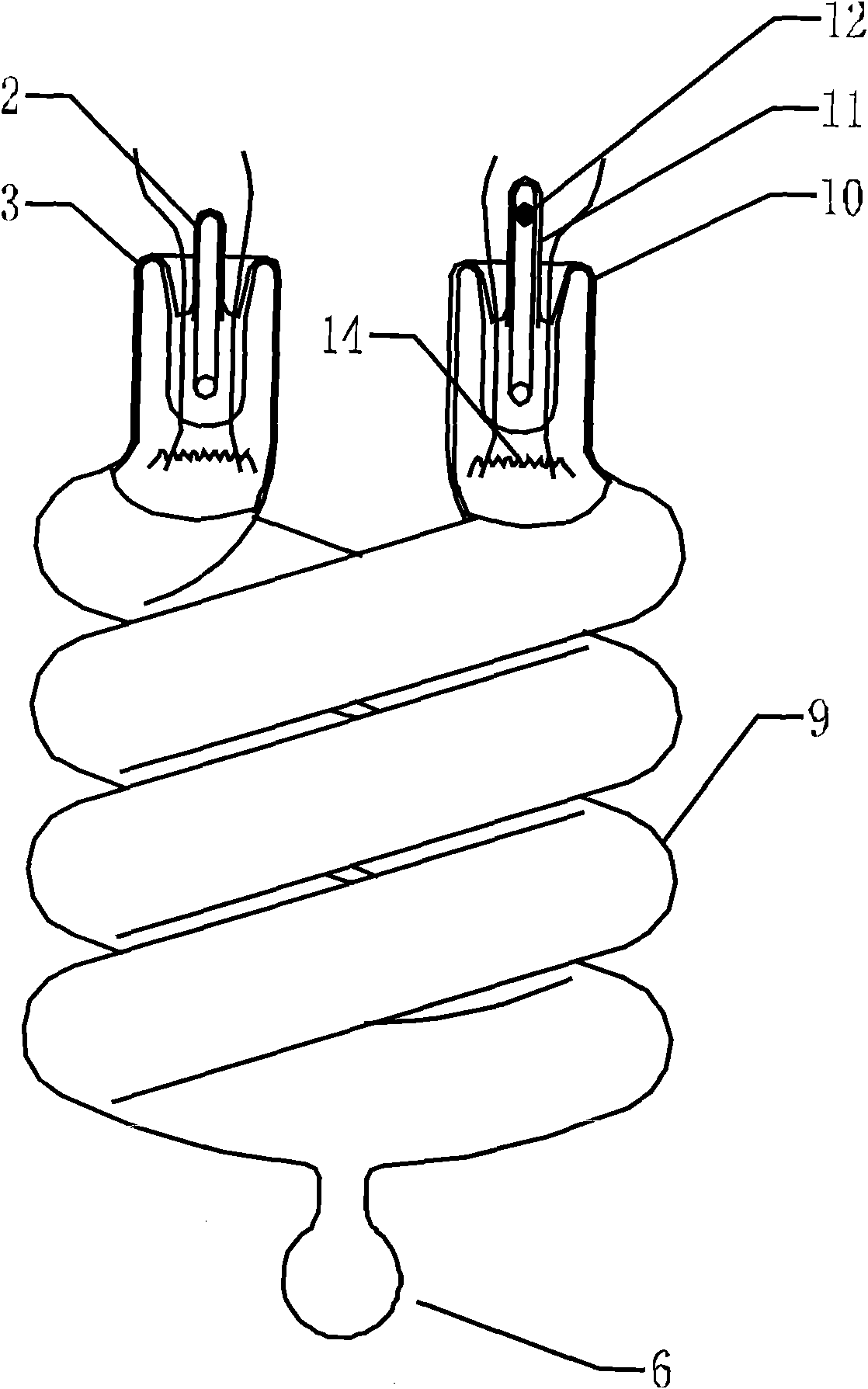

[0031] The structure and embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] The serial numbers in the accompanying drawings are explained as follows, wherein the same or similar functional components still use the same serial numbers:

[0033] 1: Upper cover 10: Lamp foot

[0034] 2: Short exhaust pipe 62: Connecting pipe

[0035] 3: lamp pin 12: amalgam

[0036] 4: base 13: lamp head

[0037] 5: Shade 14: Filament

[0038] 6: Bubble part 61: Bubble

[0039] 7: Bubble relief 17: Ballast

[0040] 8: Slowing bubbles 9: Light emitting tube

[0041] 11: Long exhaust pipe

[0042] see figure 1 , figure 2, The lamp holder 13, the upper cover 1, the lampshade 5, the base 4, the ballast 17 fixed on the base 4 and the luminous tube 9 form an energy-saving lamp with a cover. In this embodiment, the luminous tube 9 is a special-shaped spiral fluorescent tube. The short exhaust pipe 2 on the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com