Crosscut production line for metal sheet materials

A technology of sheet metal and production line, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of inaccurate positioning of sheared products, low degree of automation, poor leveling of plates, etc., to achieve good leveling effect, Higher production speed and improved cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

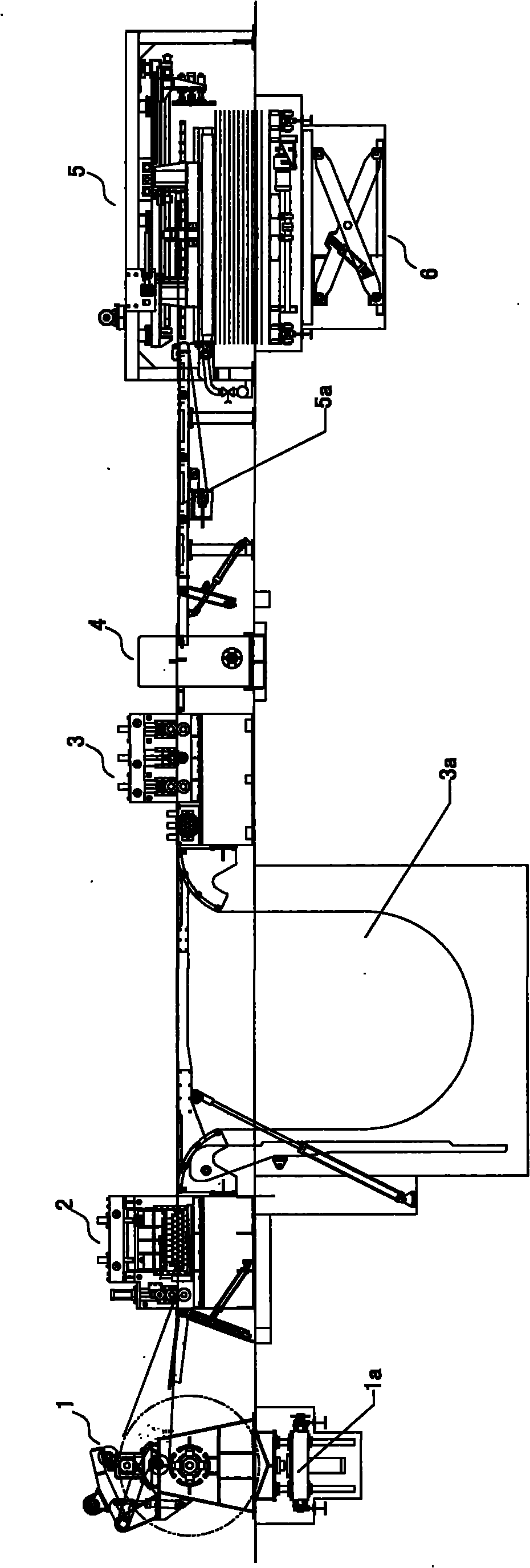

[0029] Such as figure 1 As shown, the sheet metal cross-cutting production line of the present invention includes an uncoiling unit 1, a leveling unit 2, a numerically controlled length-setting unit 3, a cross-cutting unit 4, and a stacking unit 5; The incoming roll-shaped metal sheet is unfolded, and then imported into the leveling unit 2 for leveling. After the leveled metal sheet passes through a buffer zone 3a, it enters the numerical control dimensioning unit 3, and the numerical control dimensioning unit 3 automatically adjusts it according to the input data. Control the length of the discharge material, enter the cross-cutting unit 4 for cutting, and the cut metal sheet is sent to the stacking unit 5 and the lifting receiving table 6 through the belt conveyor 5a for automatic stacking, thereby completing the entire metal sheet cross-cutting process.

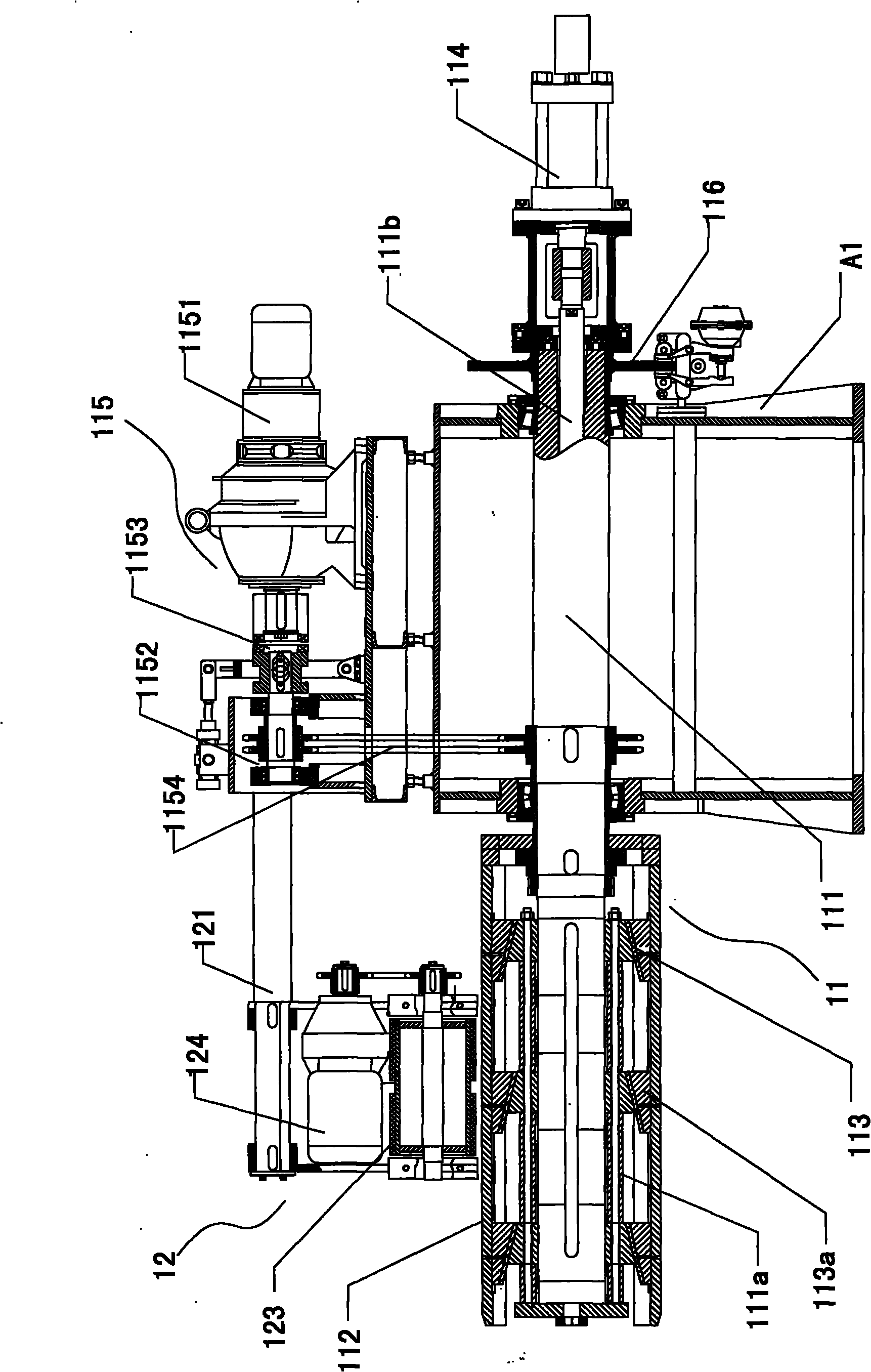

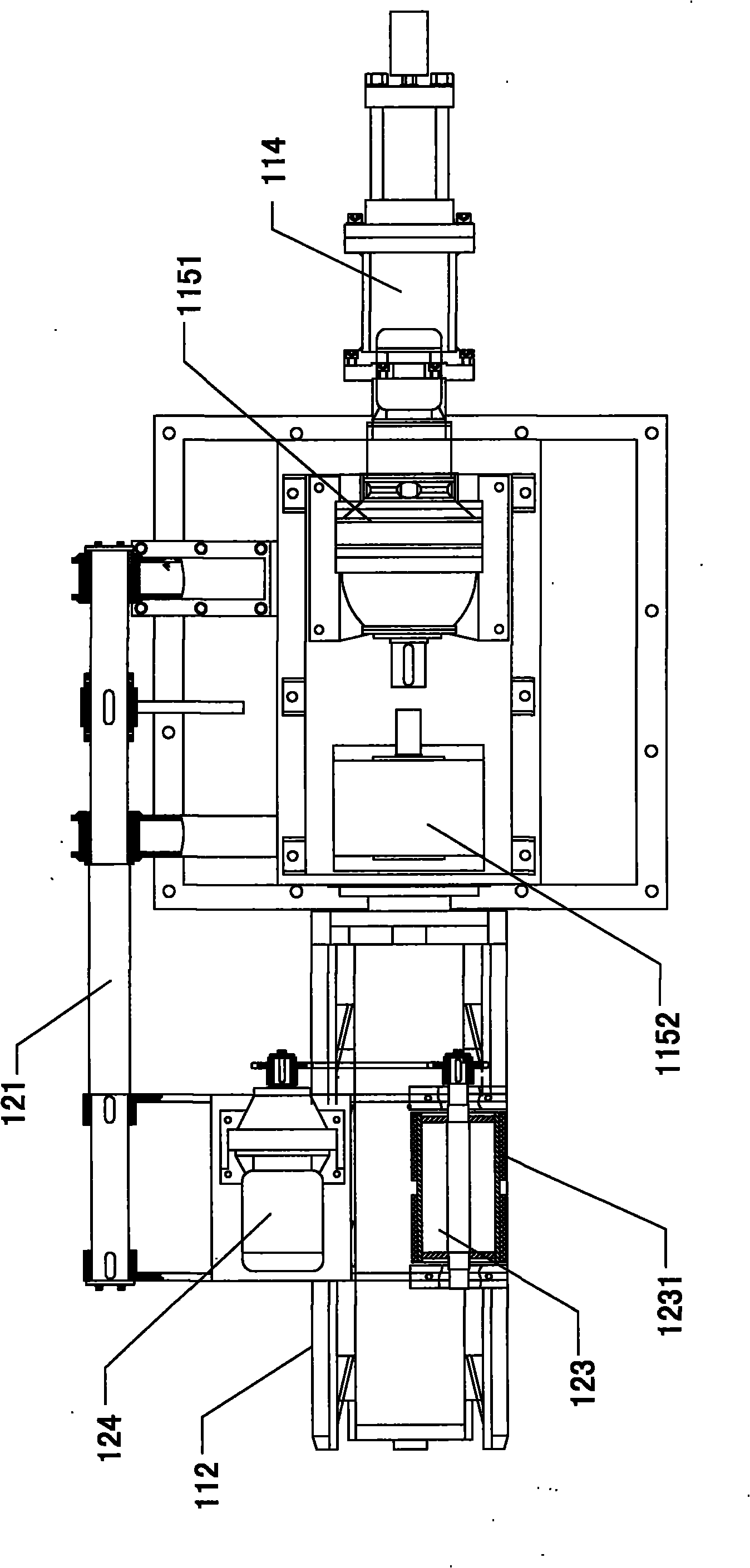

[0030] Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com