System and method for preparing sulphur-bearing granular urea

A technology of large-grain urea and urea, applied in the direction of fertilizer mixture, fertilizer form, fertilization device, etc., can solve the problems of plant loss, single urea nutrient, low nitrogen utilization rate, etc., and achieve the effect of short process, simple operation and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

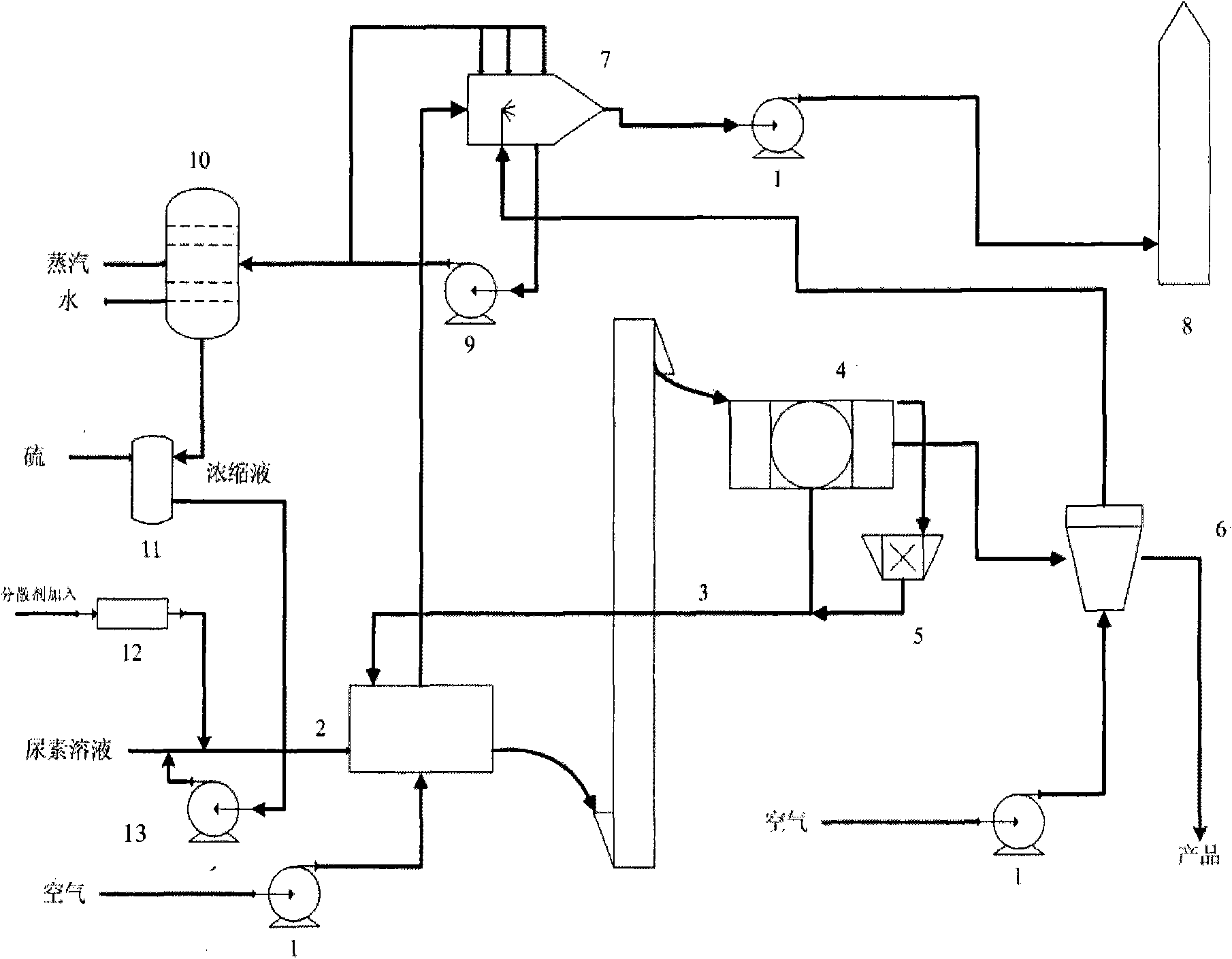

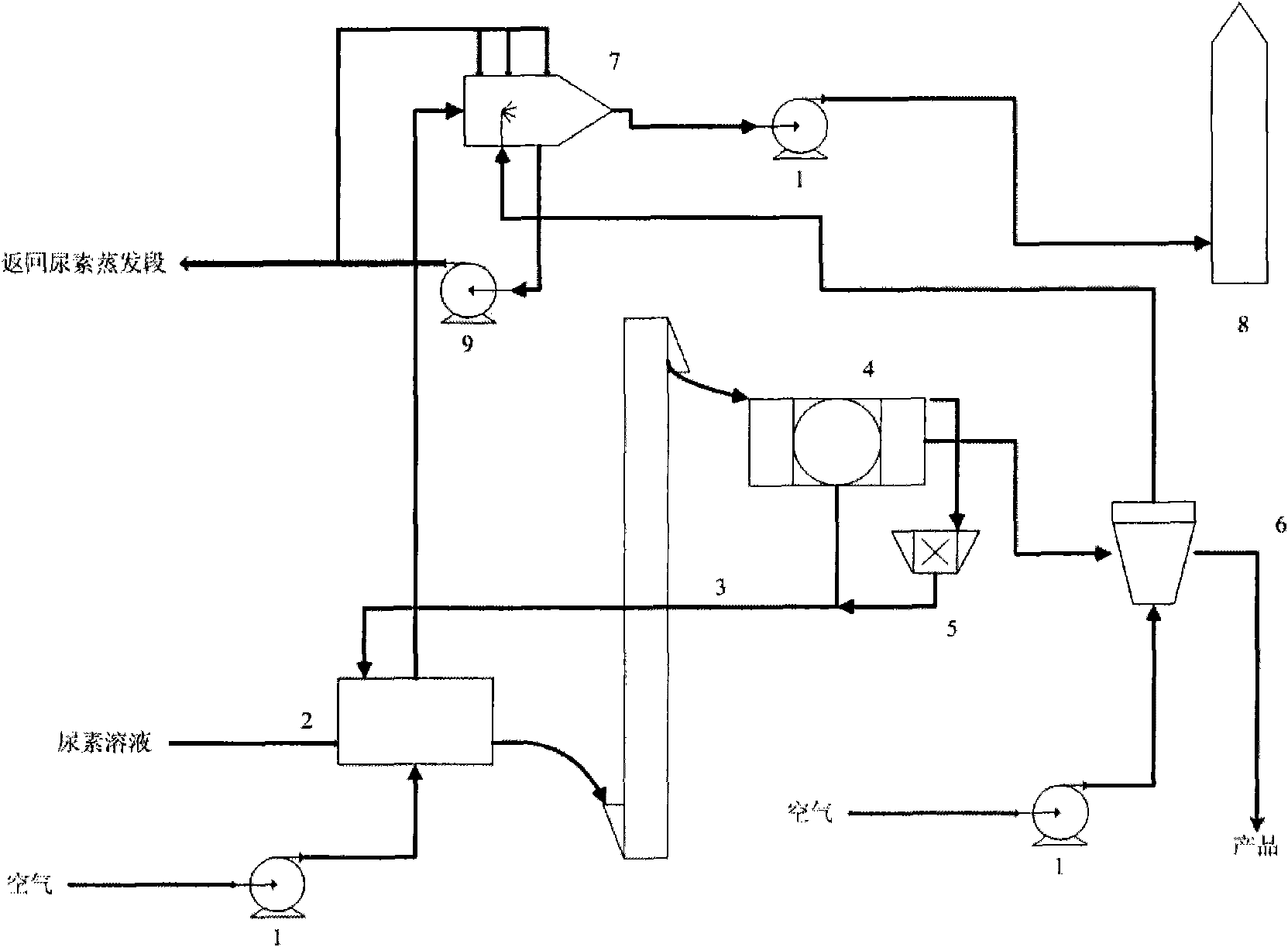

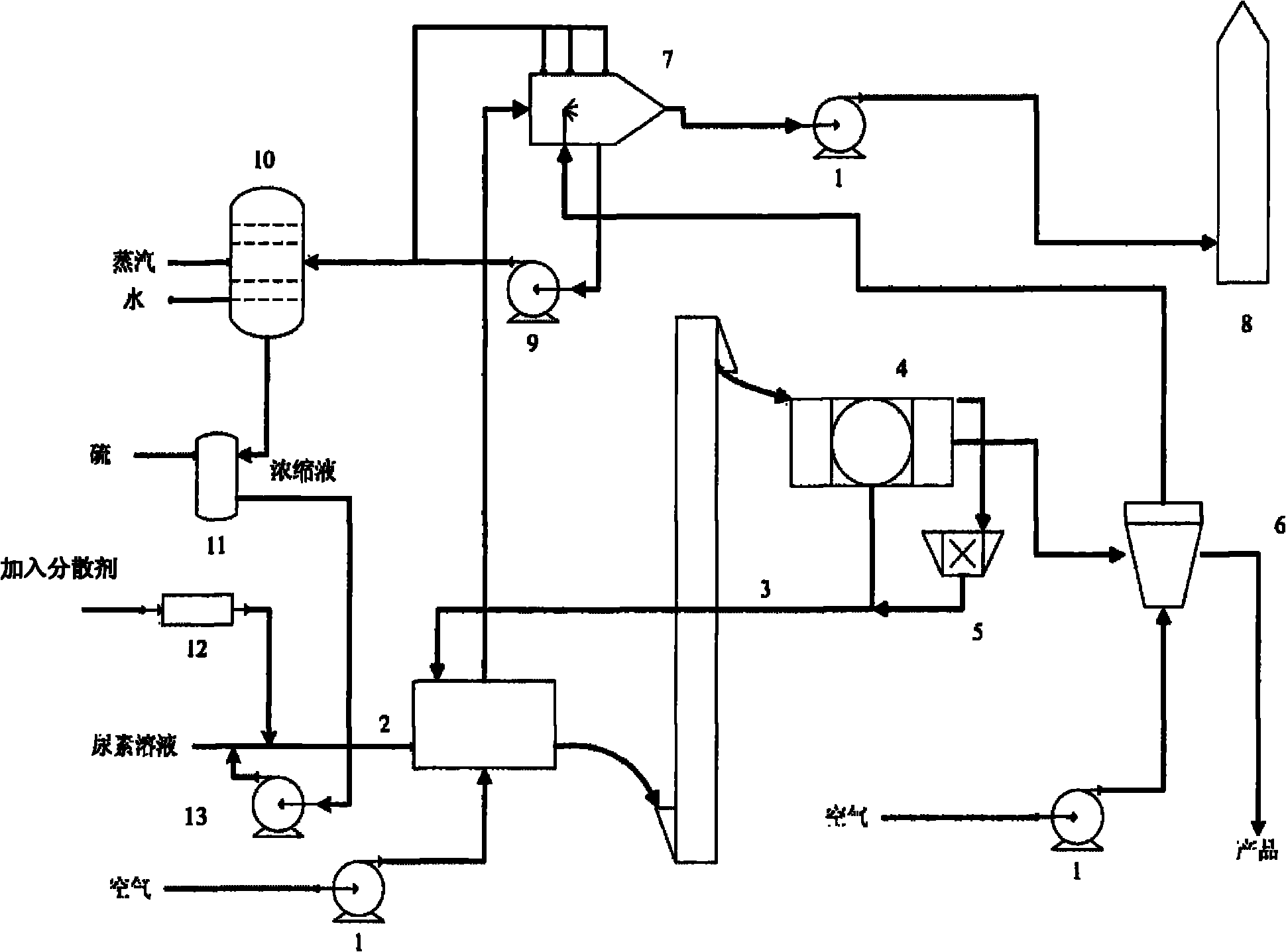

[0057] In the original large granular urea production process (see figure 1 ) on the basis of adding sulfur part, dispersant to add pump, and evaporator to form the system for preparing sulfur-containing large-grained urea according to the present invention.

[0058] The vulcanizing part includes a stirring tank 11 (including an outlet regulating valve), a vulcanizing pump 13, and the dispersant adding pump is a metering pump 12. The added equipment is shown in Table 1:

[0059] Table 1 The newly added equipment of the system of the present invention

[0060] device name

quantity

Remark

sulfur stirred tank

1

Atmospheric operating conditions

Sulfurizing pump (suitable for suspended material liquid)

1+1 (one of

Standby)

The pressure head (that is, the head of the pump) is higher than

Metering pumps

1

Dispersant dosage control

1

Simple flow control loop ...

Embodiment 2

[0074] The system for preparing sulfur-containing large granular urea described in Example 1 was used to prepare sulfur-containing large granular urea with a sulfur content of 10%.

[0075] The sulfur powder is melted in the stirring tank 11 (temperature 135° C.), and the outlet regulator of the stirring tank 11 is used to control the added mass to be 10% of the total mass, and the sulfur adding pump 13 is added to the pipeline for transporting the urea melt to be granulated Middle: adopt commercially available liquid dispersant and control its adding mass to be 0.1% of the total mass by metering pump 12, add in the pipeline that transports the urea melt to be granulated. Then the urea melt to be granulated mixed with sulfur melt and dispersant enters the fluidized bed granulator 2 for granulation, and the obtained urea granules pass through the bucket elevator 3 and enter the sieving machine 4 to be sieved (2-4 mm), and the particle size is qualified The large particle urea i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com