Manufacturing method of ring-shaped titanium alloy high-pressure cylinder

A technology for high-pressure gas cylinders and manufacturing methods, which is applied in the direction of pressure vessels, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc. It can solve problems such as no relevant reports on actual manufacturing technology, achieve convenient disassembly, and improve production efficiency , the effect of reducing the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

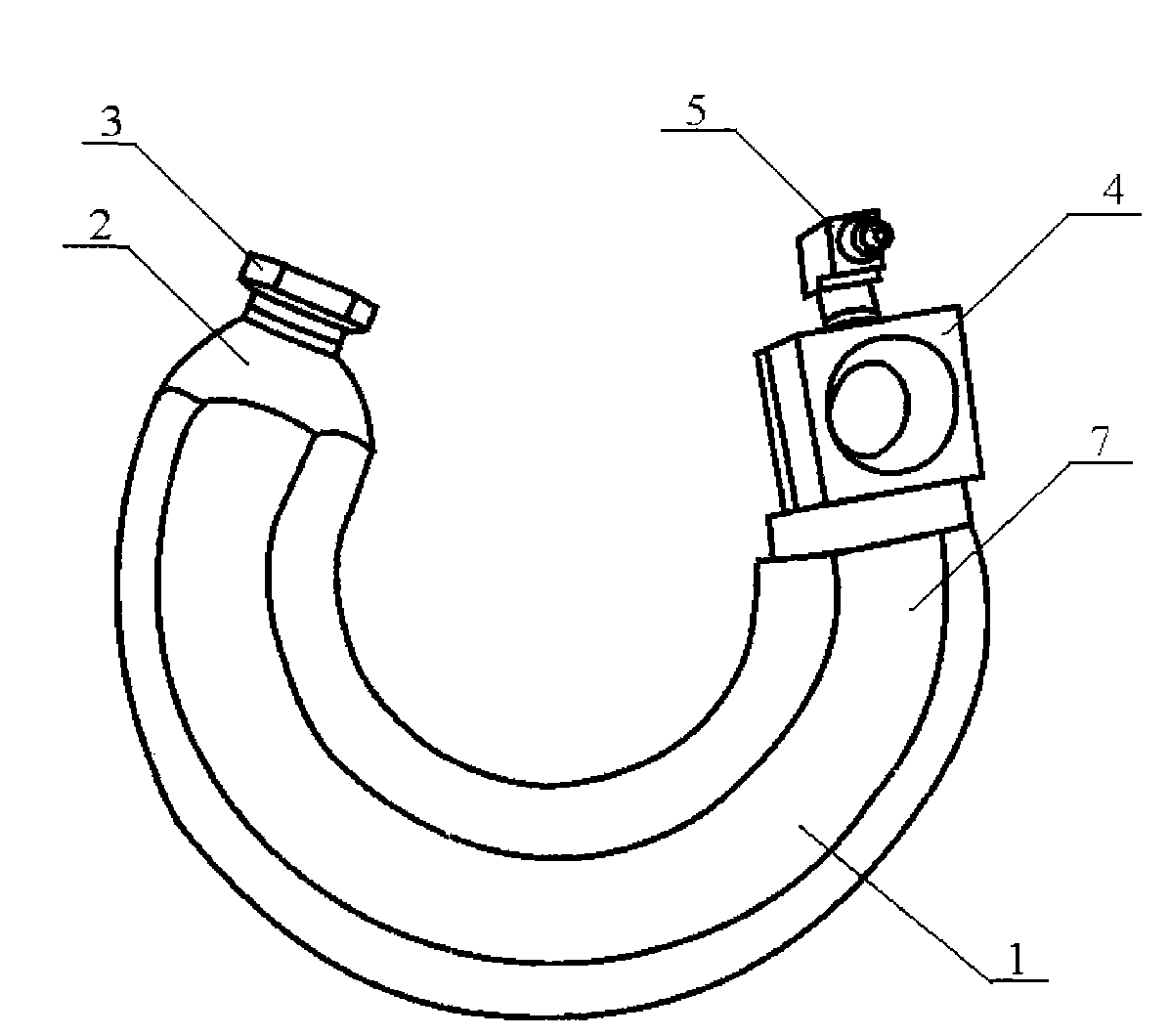

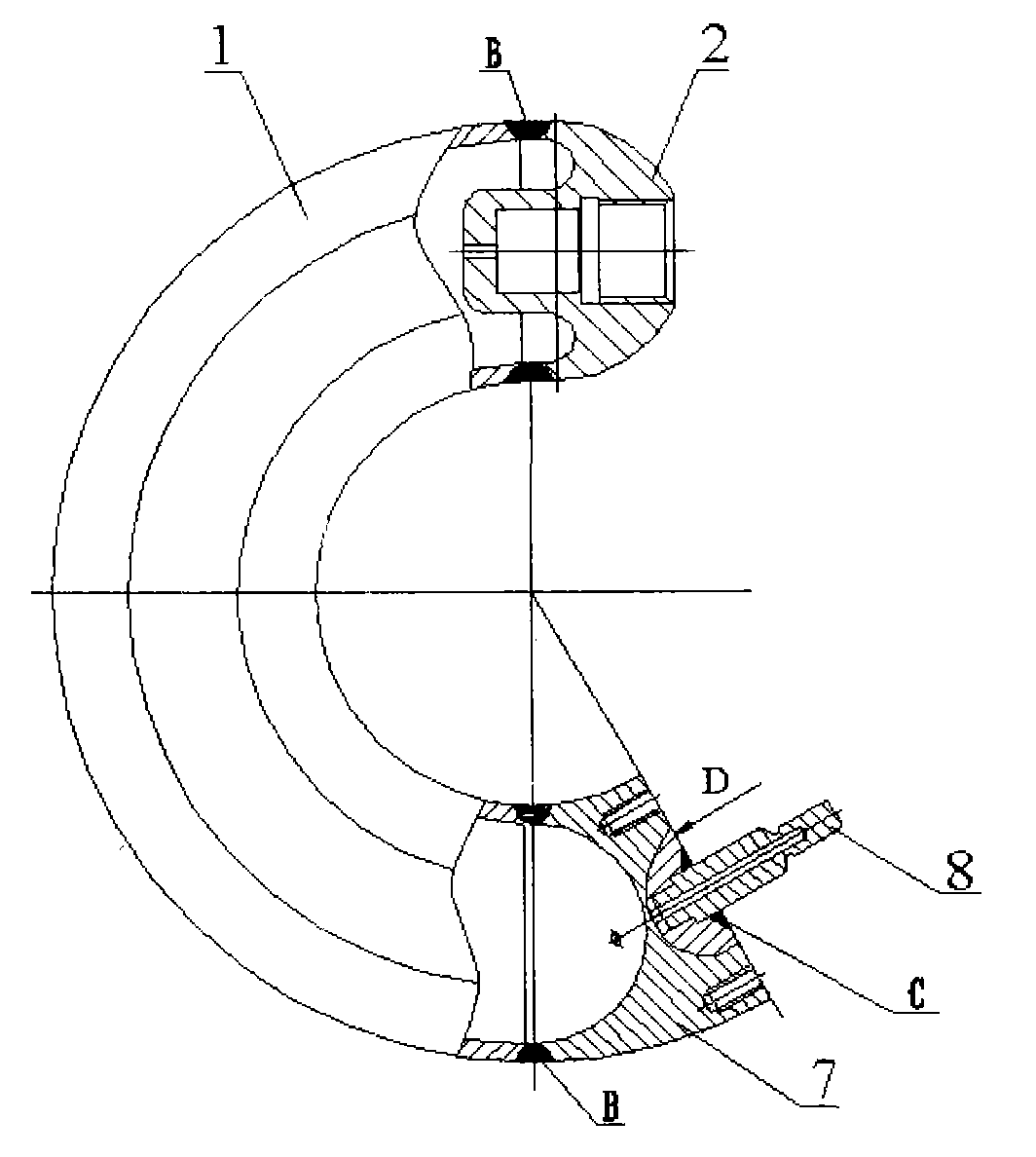

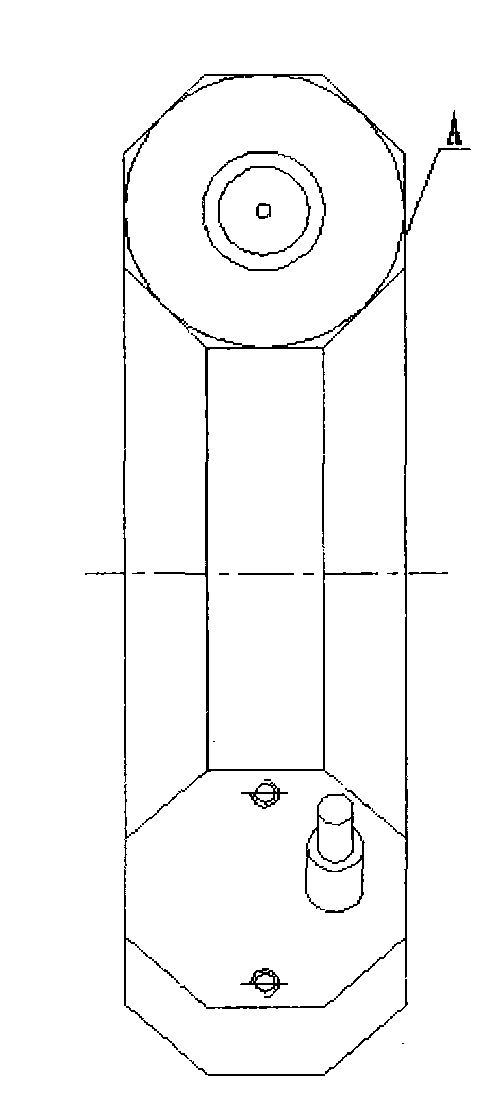

[0050] A ring-shaped titanium alloy high-pressure gas cylinder of the present invention, the material of the gas cylinder is TC4 alloy, the storage gas is nitrogen, the working pressure is 66MPa, the shape of the bottle body is a semi-circular structure, and it is equipped with a bottle head 7, a bottle tail 2 and an adapter block The manufacturing process of exhaust nozzle 5, bottle head exhaust nozzle 8 and other devices is as follows:

[0051](1) Material solution treatment: 940-960°C, heat preservation for 30 minutes, water quenching.

[0052] (2) Processing of the inner and outer rings of gas cylinders: use a whole piece of circular TC4 alloy material to process the inner and outer semi-circular rings that meet the size requirements, and finish the hollow part inside the bottle body to the required size; in the thickness direction of the inner and outer rings A 2mm machining allowance is reserved on the whole to ensure that after welding, the influence of high temperature...

Embodiment 2

[0065] The same manufacturing method as in Example 1 was adopted, that is, the material was subjected to solution treatment first, then processed and welded, and protective tooling equipment was used to manufacture a gas cylinder with a diameter of 40 mm, a wall thickness of 5 mm, and a working pressure of 40 MPa. The weld seam has passed the penetration and radiographic inspection, and the grade I is qualified, and the finished gas cylinder has passed the air tightness test and blasting test. The toughness of the material is good, the tested material strength reaches 1100Mpa, and the elongation rate is above 8%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap