Combination deashing wear-resisting device of boiler

A soot cleaning device and anti-wear technology, which is applied in the directions of damage protection, removal of solid residue, and treatment of combustion products, can solve problems such as insufficient research on boiler anti-wear, achieve the effects of reducing wear and ensuring heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

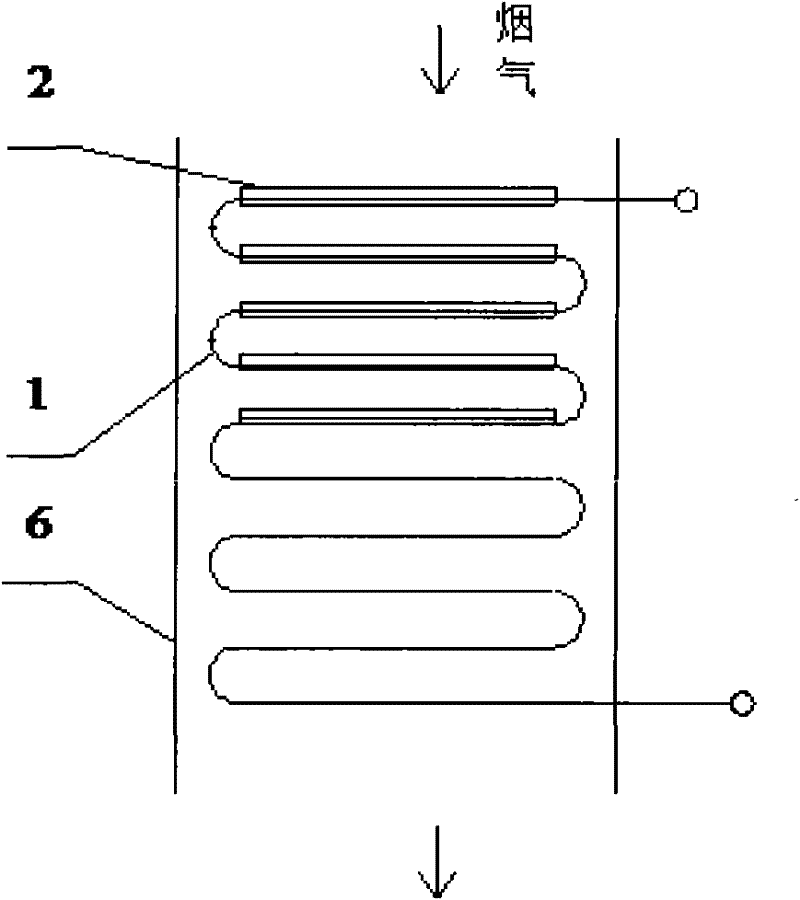

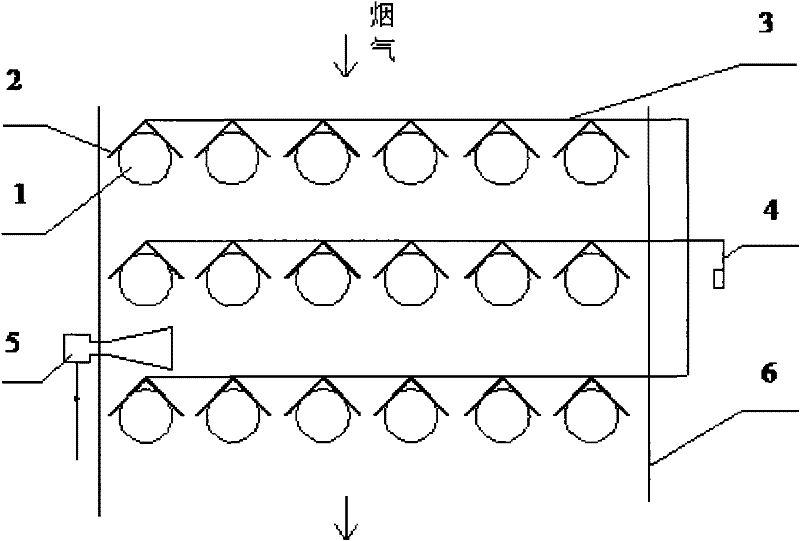

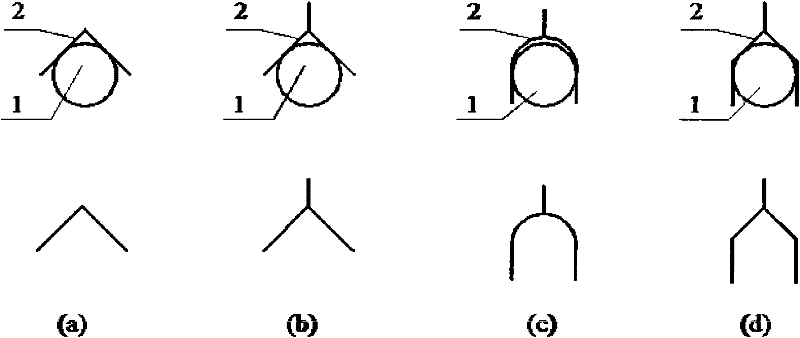

[0015] A composite dust removal and anti-wear device for a boiler according to the present invention includes a wear-resistant cover plate 2 , a connecting plate 3 , a vibrating dust removal device 4 and a shock wave dust removal device 5 . The anti-wear cover plate 2 is set on the windward side of the horizontal heat exchange tube 1 on the heating surface of the boiler, that is, the side where the flue gas of the heat exchange tube comes from. There are more than two anti-wear cover plates 2, usually one horizontal heat exchange tube 1 corresponds A wear-resistant cover 2. The flue gas flowing through the heat exchanger has a high dust concentration and a high flow velocity. On the one hand, it is easy to wear the heat exchange tubes, and on the other hand, it is easy to deposit on the heat exchange tubes. Therefore, the wear-resistant cover plates 2 are mainly arranged in the first few rows (with The flue gas flow direction is defined as front and rear) on the windward side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com