Quartz tuning fork-based nano measuring head and sample surface micro-topography measuring method

A quartz tuning fork, micro-topography technology, used in electromagnetic measuring devices, electrical/magnetic roughness/irregularity measurement, etc., can solve the problem of long contact time between probe and sample, large sample damage, and unsuitable for soft material detection and other problems, to achieve the effect of ensuring spatial resolution, short contact time, and large effective length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

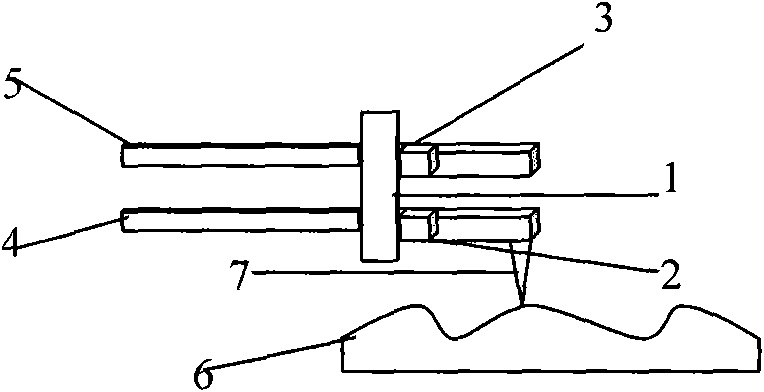

[0022] see figure 1 , the present embodiment adopts quartz tuning fork 1 as the micro force sensor of detection sample microscopic topography, and piezoelectric driver 2 is fixedly installed on a tuning fork arm of quartz tuning fork 1, and piezoelectric sensor 3 is fixedly installed on another tuning fork arm; The vibration direction of the tuning fork 1 is perpendicular to the surface of the sample. On the tuning fork arm near the side where the sample 6 is located, a tungsten probe 7 vertically pointing to the sample surface is fixedly installed, and the tungsten probe 7 forms a light weight on the surface of the sample 6. Knock mode, realize the excitation and frequency tracking of the quartz tuning fork with a phase-locked loop.

[0023] In the specific implementation, the quartz tuning fork 1 is obtained by removing the shell of the CFS308 quartz crystal oscillator, which replaces the silicon material cantilever in the AFM, and works in the tapping mode, which is differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com