Method for preparing transmission electron microscope detecting sample wafer

An electron microscope and sample technology, which is applied in the fields of material analysis and semiconductor manufacturing, can solve the problems of the polymer mask 10 destroying the extra carbon-containing layer, etc., and achieve the effect of increasing the protection ability, reducing the error and improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Figure 4 It is a flowchart of a method for preparing a TEM detection sample in an embodiment of the present invention. In combination with this figure, the method includes:

[0026] Step 1, provide initial TEM detection samples;

[0027] The initial TEM inspection sample is obtained after dicing the wafer.

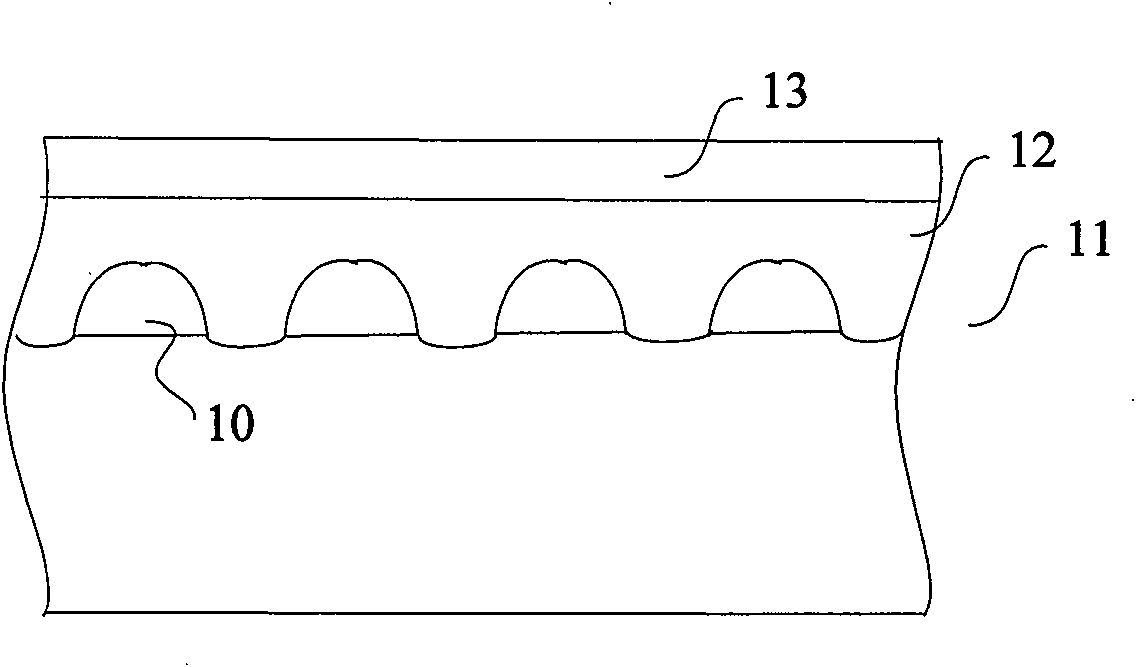

[0028] Step 2, depositing a barrier layer on the initial TEM detection sample;

[0029] The barrier layer can be made of various materials, such as platinum (Pt), platinum-palladium (Pt-Pd) alloy, palladium (Pd), gold (Au) or chromium (Cr), etc.; the barrier layer is usually deposited by physical vapor deposition Process (PVD) deposition, of course, if the deposition of the barrier layer can be achieved and the conventional requirements for sample preparation are met, other processes can also be used;

[0030] In order to realize effective protection for the initial TEM detection sample, it should be ensured that the barrier layer completely covers the surface o...

Embodiment

[0041] Taking the production of the TEM detection sample of the background technology as an example, the preparation process of this embodiment includes:

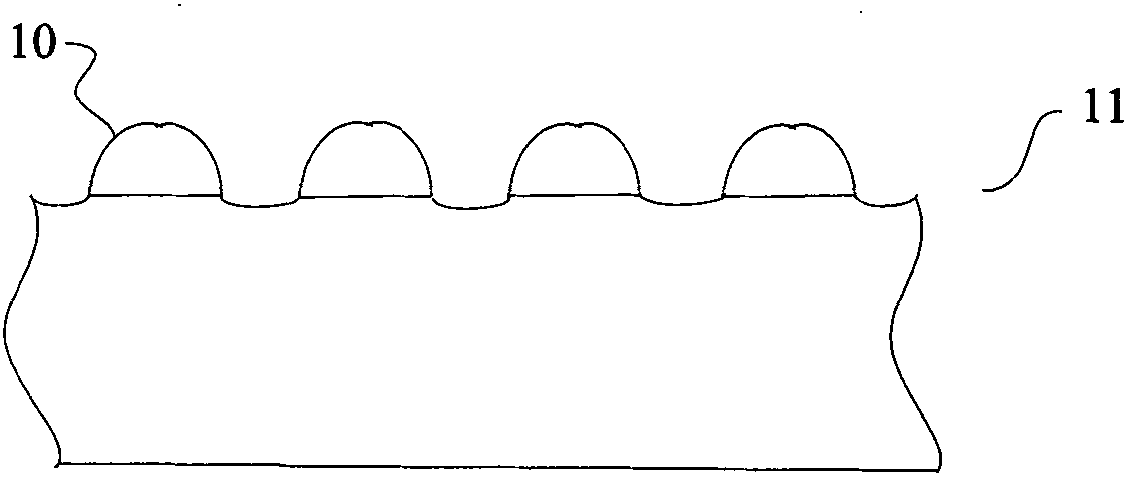

[0042] refer to Figure 5A , provide an initial TEM detection sample 51, the initial TEM detection sample 51 includes a Polymer mask 50; obtain the initial TEM detection sample 51 after dicing the wafer. .

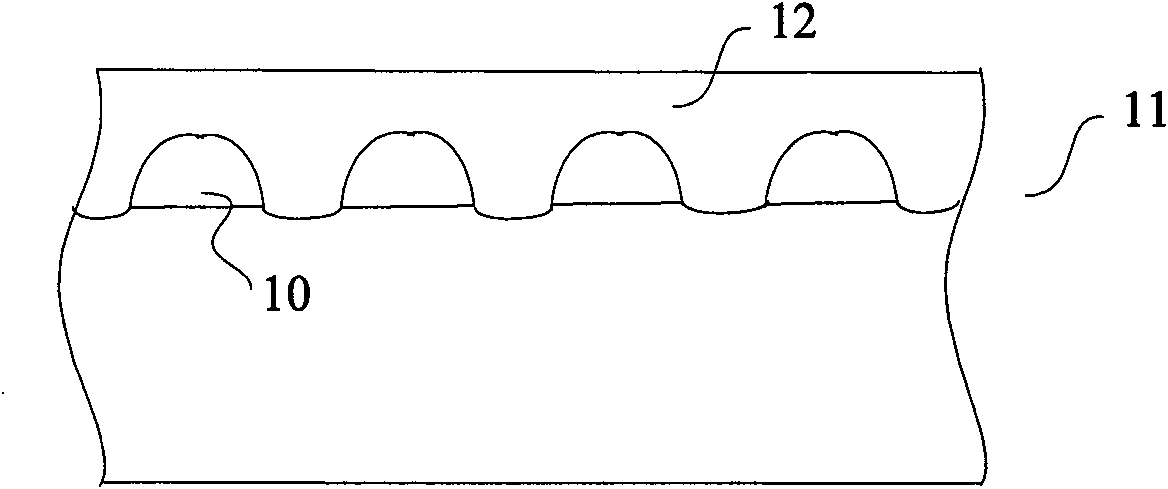

[0043] refer to Figure 5B , depositing a barrier layer 52 on the initial TEM detection sample 51;

[0044] In this embodiment, a Pt layer with a thickness greater than 20 nanometers is deposited as the barrier layer 52 by using PVD technology, and the specific process conditions include: a DC voltage of 0.4 kV, a vacuum pressure of 6 pascals, and a sample distance of 30 mm. represents the distance from the initial TEM detection sample 51 to the Pt target, and the Pt target is used to sputter Pt particles to form the barrier layer 52 on the initial TEM detection sample 51 . Based on the above process conditions, tho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com