Tunneling field-effect transistor and manufacturing method thereof

A technology of tunneling field effect and manufacturing method, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of reduced driving current and increased leakage current of tunneling transistors, and achieves increased driving current and reduced leakage current. Effect of small, reduced alignment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

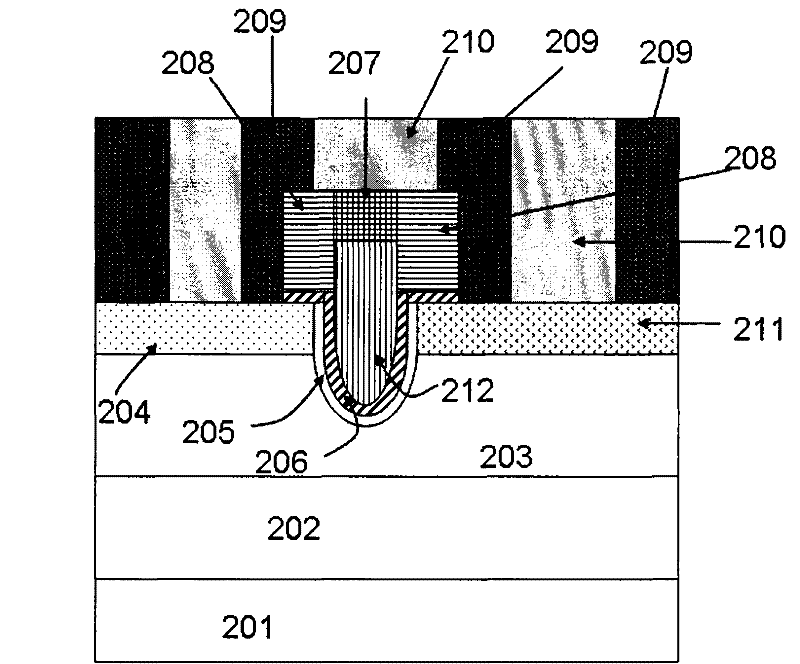

[0062] figure 2 It is an embodiment of the semiconductor recessed channel tunneling device disclosed in the present invention, and it is a cross-sectional view along the channel length direction of the device. This device has a gate stack region, a source region, a drain region, and a substrate region. The gate stack region is composed of an insulating layer 205, an insulating layer 206, a conductor layer 207 and a conductor layer 212. The insulating layer 205 is thermally oxidized grown or deposited silicon dioxide. The insulating layer 206 is a high dielectric constant medium. The conductive layer 207 is polysilicon, and the conductive layer 212 is a metal layer. The sidewall 208 of the gate stack area is an insulator such as Si 3 N 4 They insulate the gate conductor layer from the other conductor layers of the device. The doping type of the source doping region 211 is generally opposite to the doping type of the drain doping region 204, and is generally the same as the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com