Method for hydrogenating itaconic acid

A technology for hydrogenating itaconic acid and itaconic acid, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as large water consumption, and achieve the effects of reducing costs and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

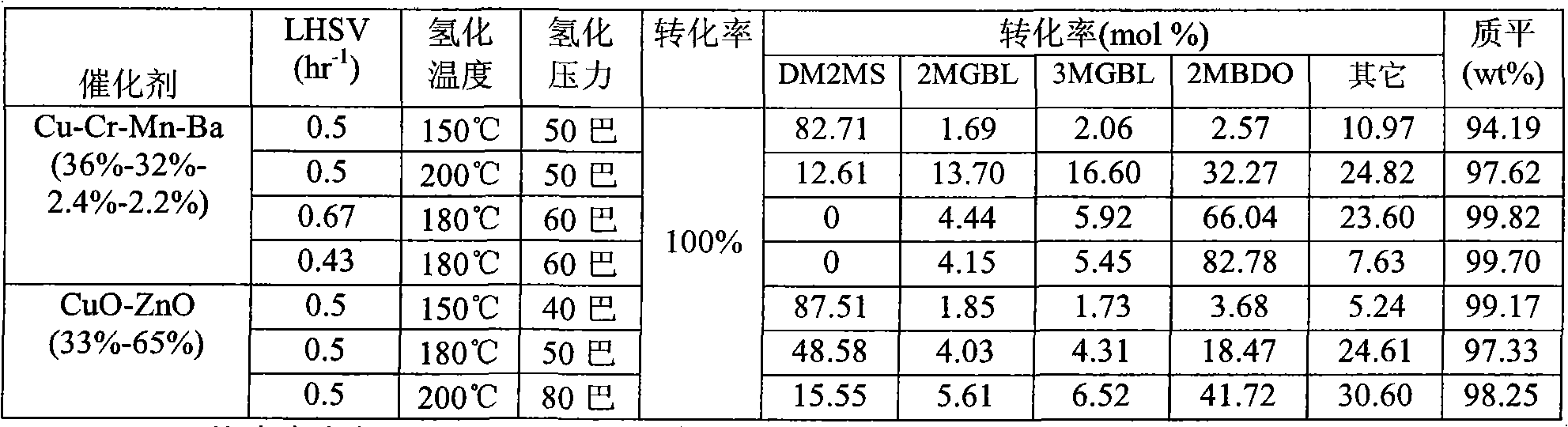

Image

Examples

Embodiment 1

[0011] Embodiment 1, esterification itaconic acid

[0012] Take 50 g of itaconic acid (Aldrich manufacturer and product model I-2920-4), 247 g of methanol, and 3.68 g of p-toluenesulfonic acid in an autoclave reactor, and spontaneously generate 5 bar at a reaction temperature of 150 ° C. After reacting under pressure for 1 hour, the molar yield of dimethyl itaconate was 92.10% with gas chromatographic analysis of crude product composition, and the dimethyl itaconate of 53.21g was obtained through distillation, and the productive rate was 87.53%. The boiling point of dimethyl itaconate is 210°C.

Embodiment 2

[0013] Embodiment 2, esterification itaconic acid

[0014] Take 50 g of itaconic acid (Aldrich manufacturer and product model I-2920-4), 177 g of ethanol, and 3.68 g of p-toluenesulfonic acid in an autoclave reactor, and spontaneously generate 3 bar at a reaction temperature of 100 ° C. After reacting under pressure for 3 hours, the molar yield of diethyl itaconate was 74.69% with gas chromatographic analysis of the crude product composition, and the diethyl itaconate of 50.98g was obtained through distillation, and the yield was 71.26%. The boiling point of diethyl itaconate is 235°C.

Embodiment 3

[0015] Embodiment 3, esterification itaconic acid

[0016] Take 50 g of itaconic acid (Aldrich manufacturer and product model I-2920-4), 352 g of ethanol, and 3.68 g of p-toluenesulfonic acid in an autoclave reactor, and spontaneously generate 3 bar at a reaction temperature of 100 ° C. After reacting under pressure for 3 hours, the molar yield of diethyl itaconate was 91.98% with a gas chromatographic analysis of the crude product composition, and the diethyl itaconate of 61.62g was obtained through distillation, and the yield was 86.11%. The boiling point of diethyl itaconate is 235°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com