Device for testing metal melt electrical resistivity and testing method therefor

A metal melt and testing method technology, applied in the direction of measuring device, measuring resistance/reactance/impedance, measuring electrical variables, etc., can solve the problems of easy oxidation pollution of test samples, low measurement accuracy, complicated operation, etc., and achieve simple structure , good heat resistance, and the effect of increasing the applicable temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

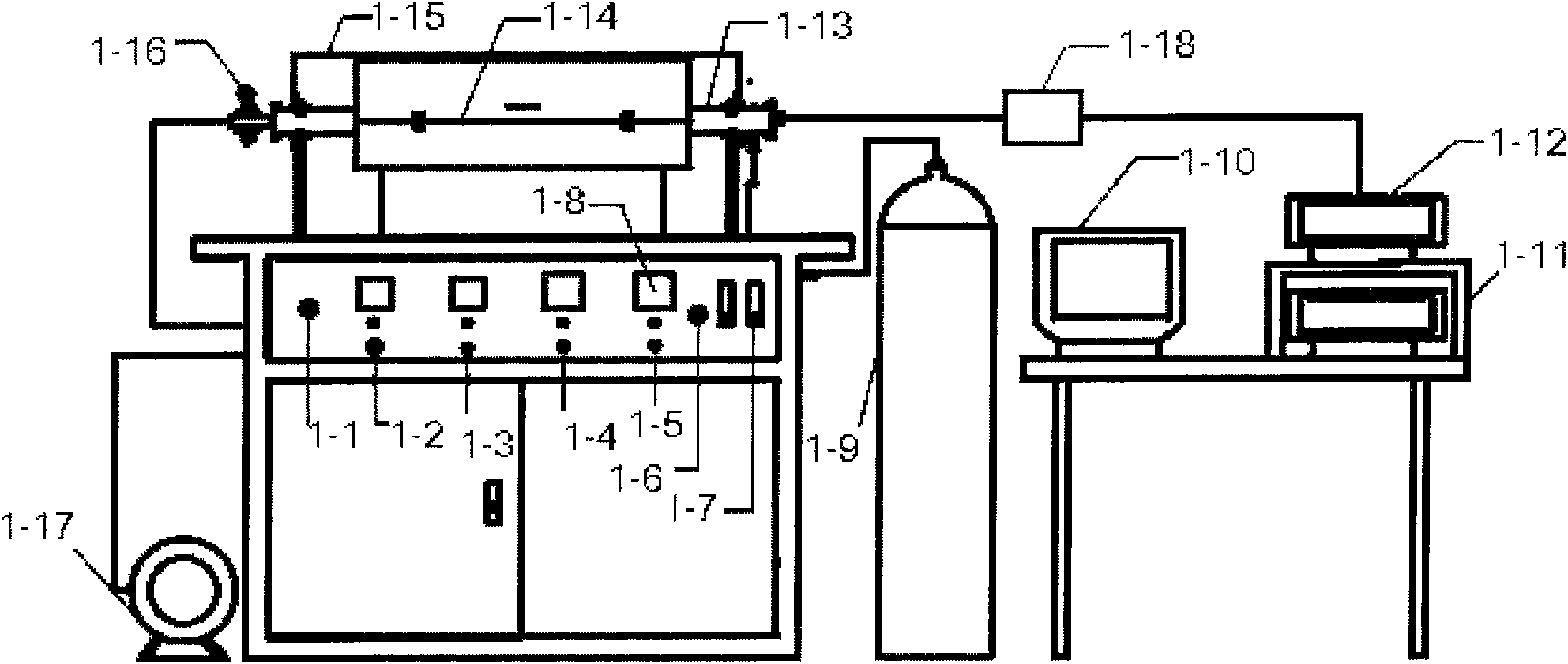

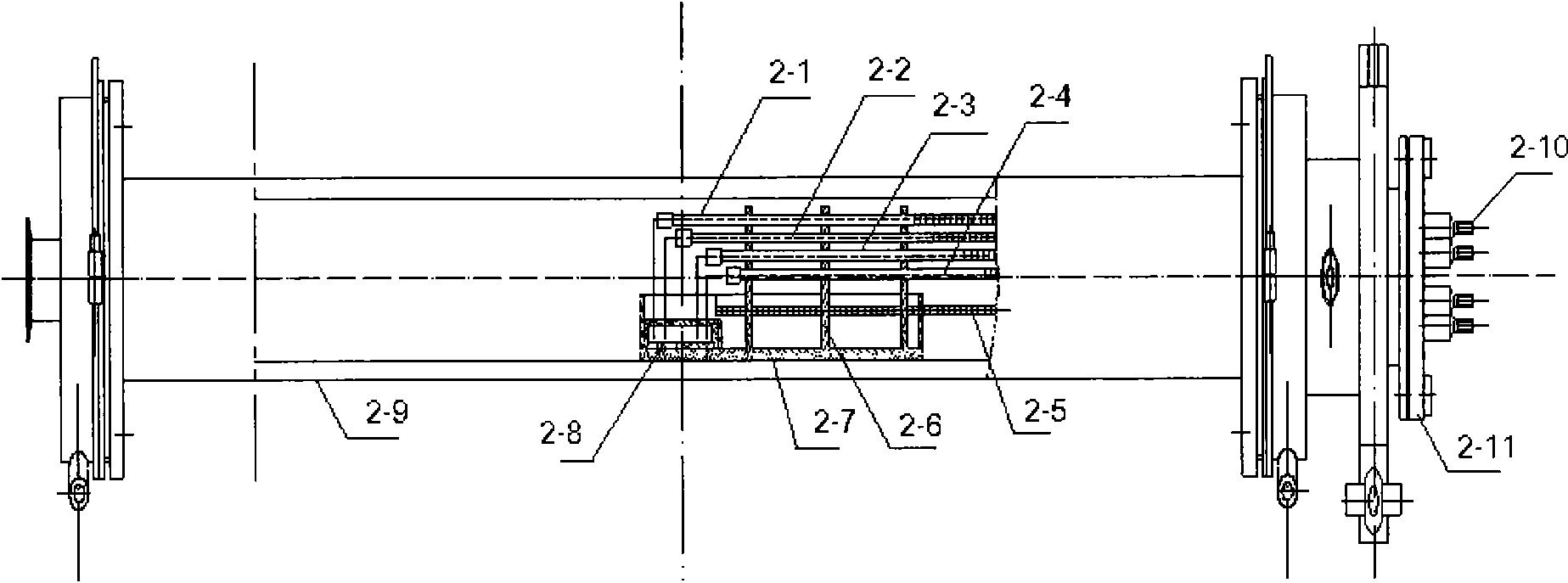

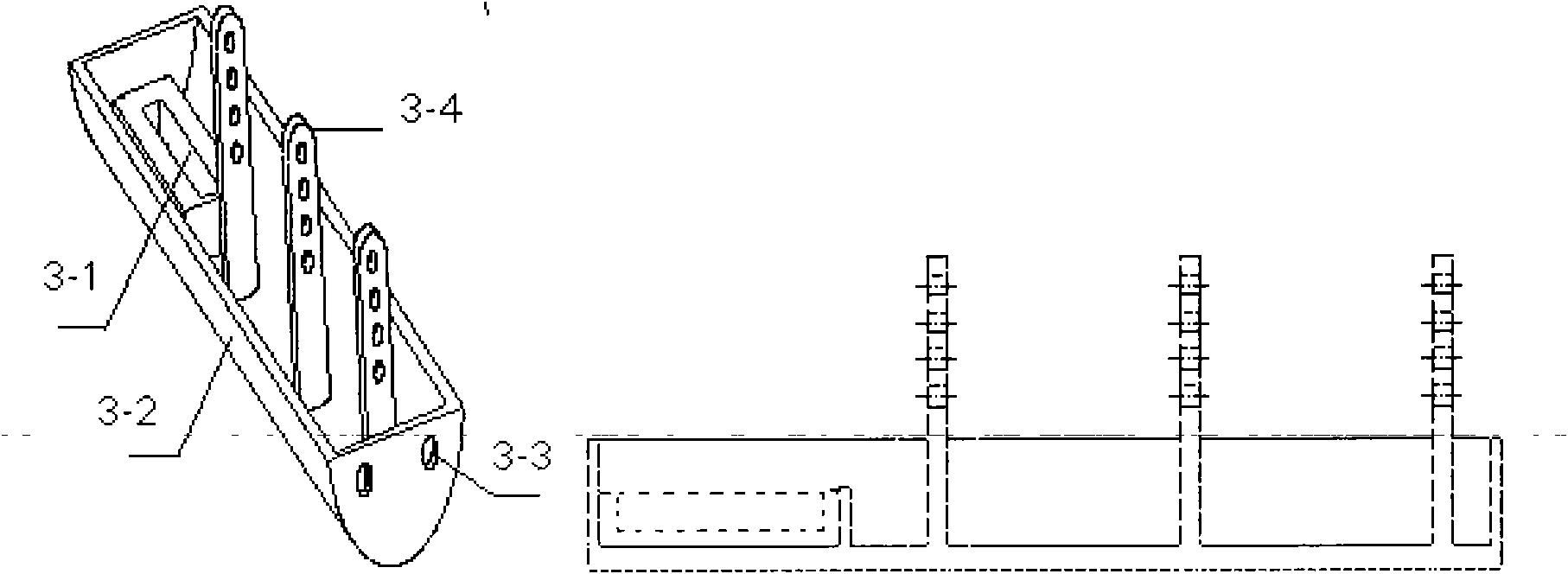

[0042] Refer to the attached figure 2, which shows a device for testing the resistivity of a molten metal, including a sample positioning device, a gas protection system with a heating device for accommodating the sample positioning device to form an airtight protection, and the An electrical performance testing system for performing electrical performance tests on samples, wherein the electrical performance testing system includes four electrodes 2-1, 2-2, 2-3, 2-4 and thermocouples 2-5, and the sample positioning device includes a belt A crucible 2-8 for accommodating a sample with a cover and a ceramic boat 2-7 as a carrier of the crucible, wherein the crucible is positioned at a predetermined position of the ceramic boat, and the cover is provided for the The holes for positioning the four electrodes on the cover plane, the ceramic boat is provided with holes 3-3 for thermocouple positioning, and the ceramic boat is provided with brackets 2-6 for fixing and positioning th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com