Embedded type integrated monitoring and maintenance system of concrete block forming production line

A concrete block and maintenance system technology, applied in the general control system, control/regulation system, closed-circuit television system, etc., can solve the problem of no video acquisition and audio acquisition and processing, inability to acquire on-site video and audio signals, and Ethernet transmission congestion and other problems, to achieve the effect of complete functions, wide application and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

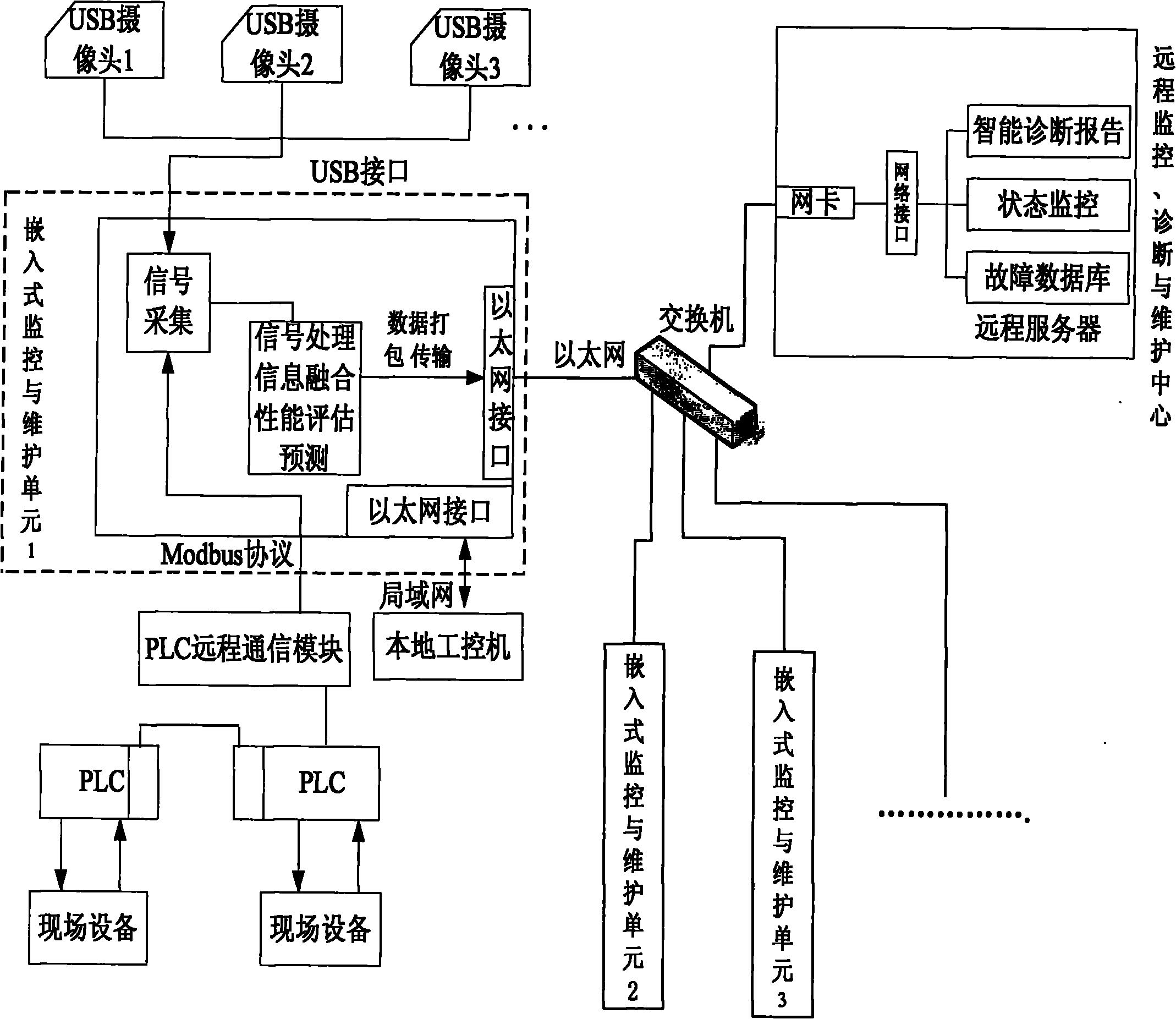

[0013] combine figure 1 , based on the overall design of the embedded integrated monitoring and maintenance system as figure 1 As shown, the embedded integrated monitoring and maintenance system of the concrete block forming production line of the present invention, the system is based on the network function structure of the B / S mode, the on-site signal acquisition module is connected with the embedded monitoring and maintenance unit, and the embedded monitoring and maintenance unit Connected with the remote monitoring, diagnosis and maintenance center, the embedded monitoring and maintenance unit, on the one hand, can realize the collection, compression and transmission of other kinds of information, and realize the diversification of information; on the other hand, it replaces the control system composed of PLC The on-site host computer in the system prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com