Permanent magnet liquid cooling retarder for vehicle

A technology of retarder and permanent magnet, which is applied in the direction of cooling/ventilation device, magnetic circuit static parts, magnetic circuit shape/style/structure, etc. Problems such as braking torque and poor heat dissipation effect of air cooling, etc., achieve the effect of simple action, good heat dissipation effect and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

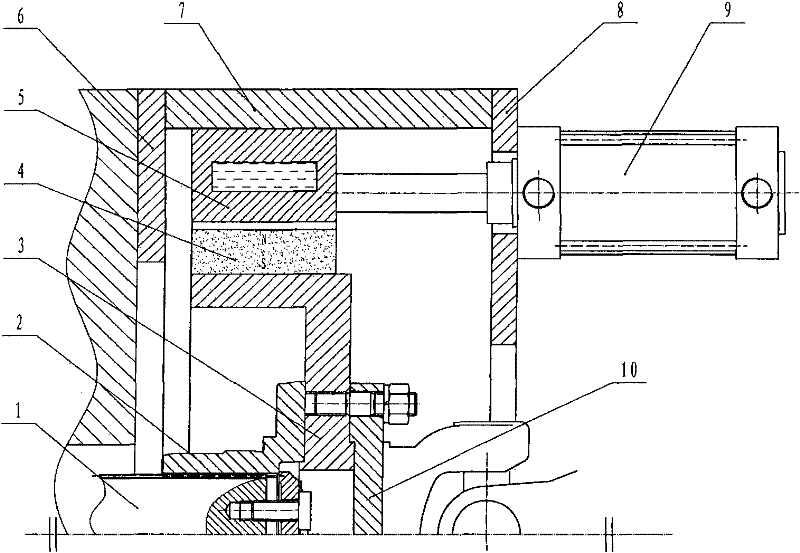

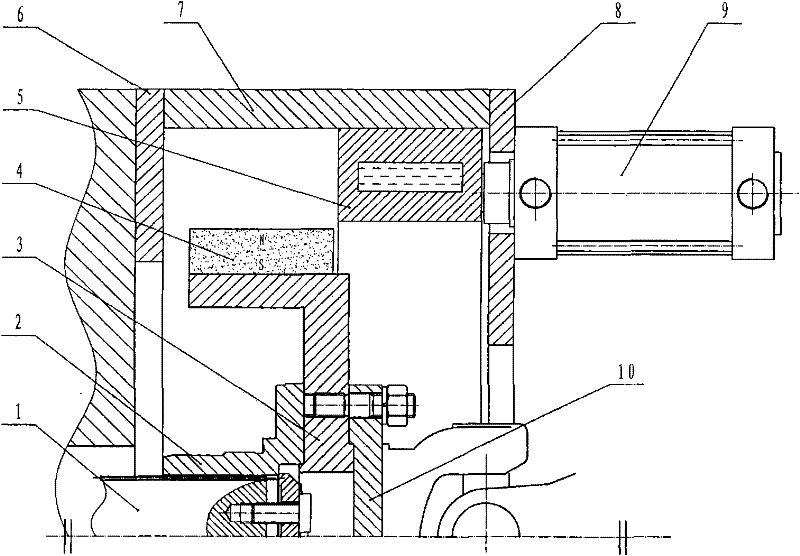

[0027] Embodiment 1 of the present invention is used for retarder to install the structure of gearbox rear body, as figure 1 with figure 2 . The left end cover 6 of the retarder is used for connecting and positioning the retarder and the gearbox, the outer shell 7 is fixed with the left end cover 6 of the retarder, and the right end cover 8 of the retarder is fixed with the outer shell 7. The stator 5 is provided with a water channel for cooling, and 1-2 cylinders 9 are fixed on the right end cover 8 of the retarder, and the pistons of the cylinders 9 are fixed with the stator 5 . 12-20 tile-shaped permanent magnets 4 are evenly distributed on the magnet holder 3 along the circumference, and the outer diameter of the permanent magnets 4 and the inner diameter of the stator drum 5 maintain a gap of 0.5-2.0 mm. The transmission output shaft 1 transmits power to the magnet holder 3 through the output shaft flange 2, and then transmits power to the automobile transmission shaft...

Embodiment 2

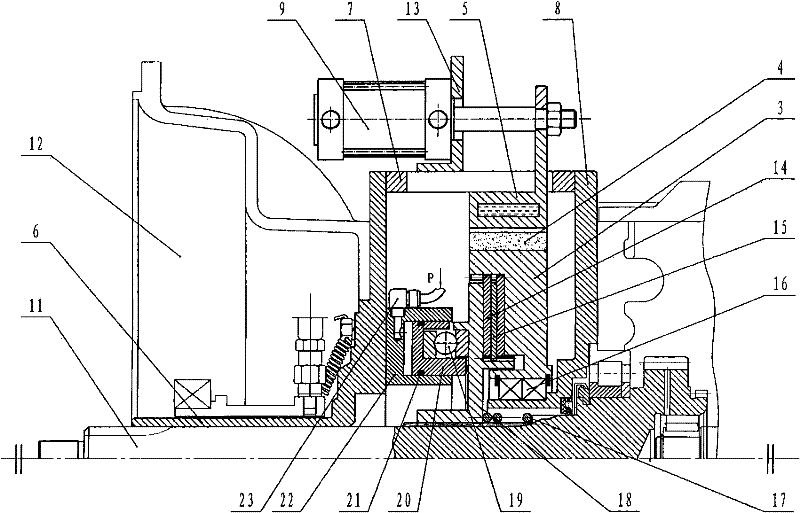

[0037] Embodiment 2 of the present invention is used for the structure that the speed retarder is installed between the gearbox and the clutch, such as image 3 . The left end cover 6 of the retarder is fixed to the clutch housing 12, the cylinder bracket 13 is fixed on the circumference of the casing 7, 1-2 cylinders 9 are fixed on the cylinder bracket 13, the casing 7 is fixed to the right end cover 8 of the retarder, and the right end of the retarder The cover 8 is fixed on the gearbox front body. There is a square groove on the circumference of the casing 7, and the boss protruding from the stator 5 is fixed with the piston of the cylinder 9 through a nut, and the piston can push and pull the stator 5 axially. Figure 8 or Figure 9 way to connect. 12-20 tile-shaped permanent magnets 4 are evenly distributed on the magnet holder 3 along the circumference, and the outer diameter of the permanent magnets 4 and the inner diameter of the stator drum 5 maintain a gap of 0.5-...

Embodiment 3

[0042] Embodiment 3 of the present invention is used to install the structure in the middle of the transmission shaft for the retarder, and is particularly suitable for being installed on automobiles with longer transmission shafts, such as Figure 5 . Divide the transmission shaft of ordinary automobiles into two sections, and install the retarder structure in the middle. The independent shaft flange 25 is connected with the drive shaft universal joint 24 at the transmission output end, and the two ends of the independent shaft 26 are respectively connected with an independent shaft flange 25 . Through the positioning bearing 16, the left end cover 6 of the retarder and the right end cover 8 of the retarder are coaxial with the independent shaft 25, and are fixed into a whole with the shell 7, and the shell 7 is fixed on the vehicle frame. The magnet holder 3 is fastened to the independent shaft 26 and rotates together with the independent shaft 26 . 12-20 tile-shaped perma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com