Vaporizer, material gas supply system including vaporizer and film forming apparatus using such system

A raw material gas and vaporizer technology, applied in electrical components, gaseous chemical plating, metal material coating process, etc., can solve the problems of no heat supply, low thermal conductivity, low thermal conductivity, etc., achieve simple structure and improve thermal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

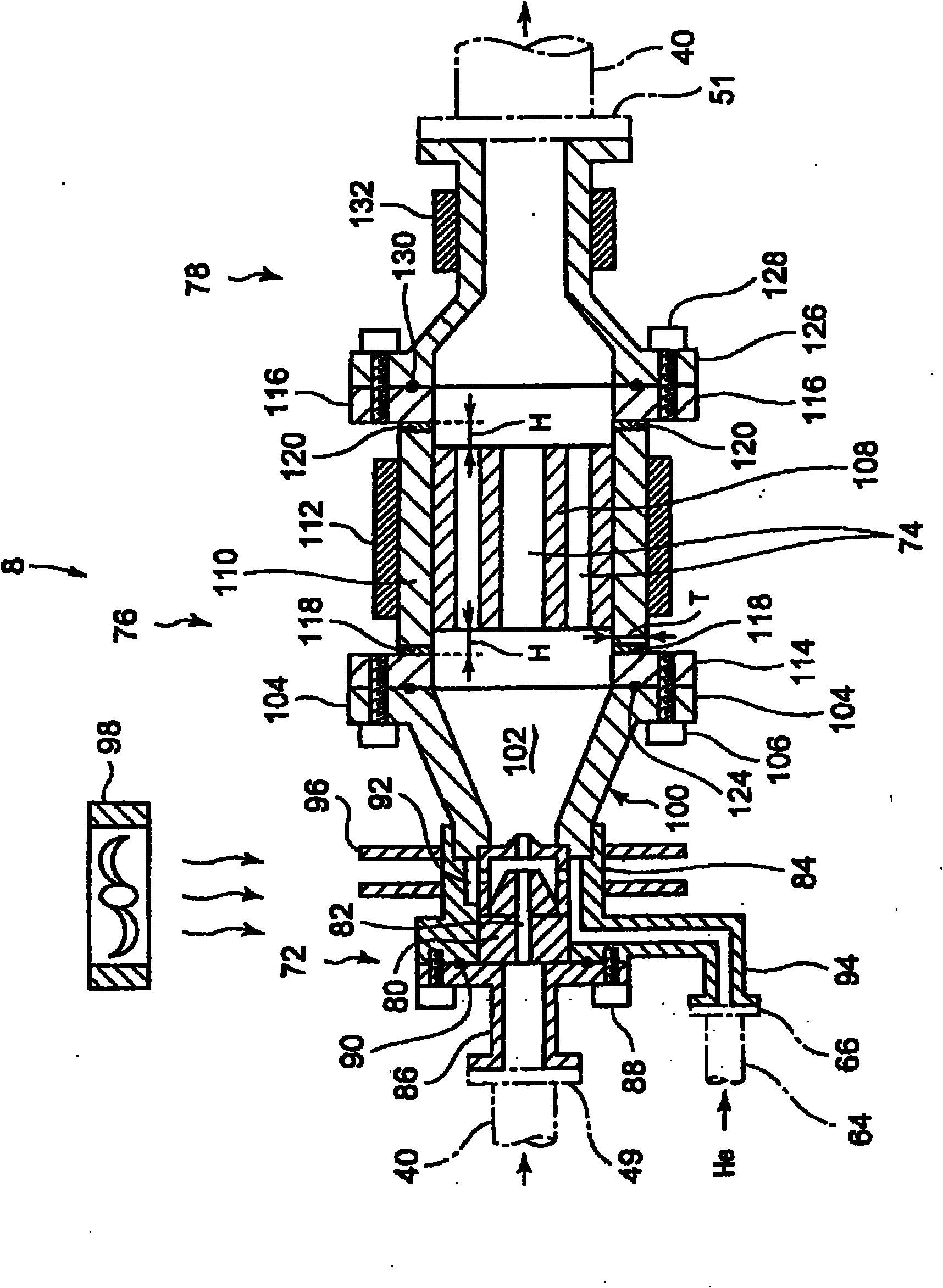

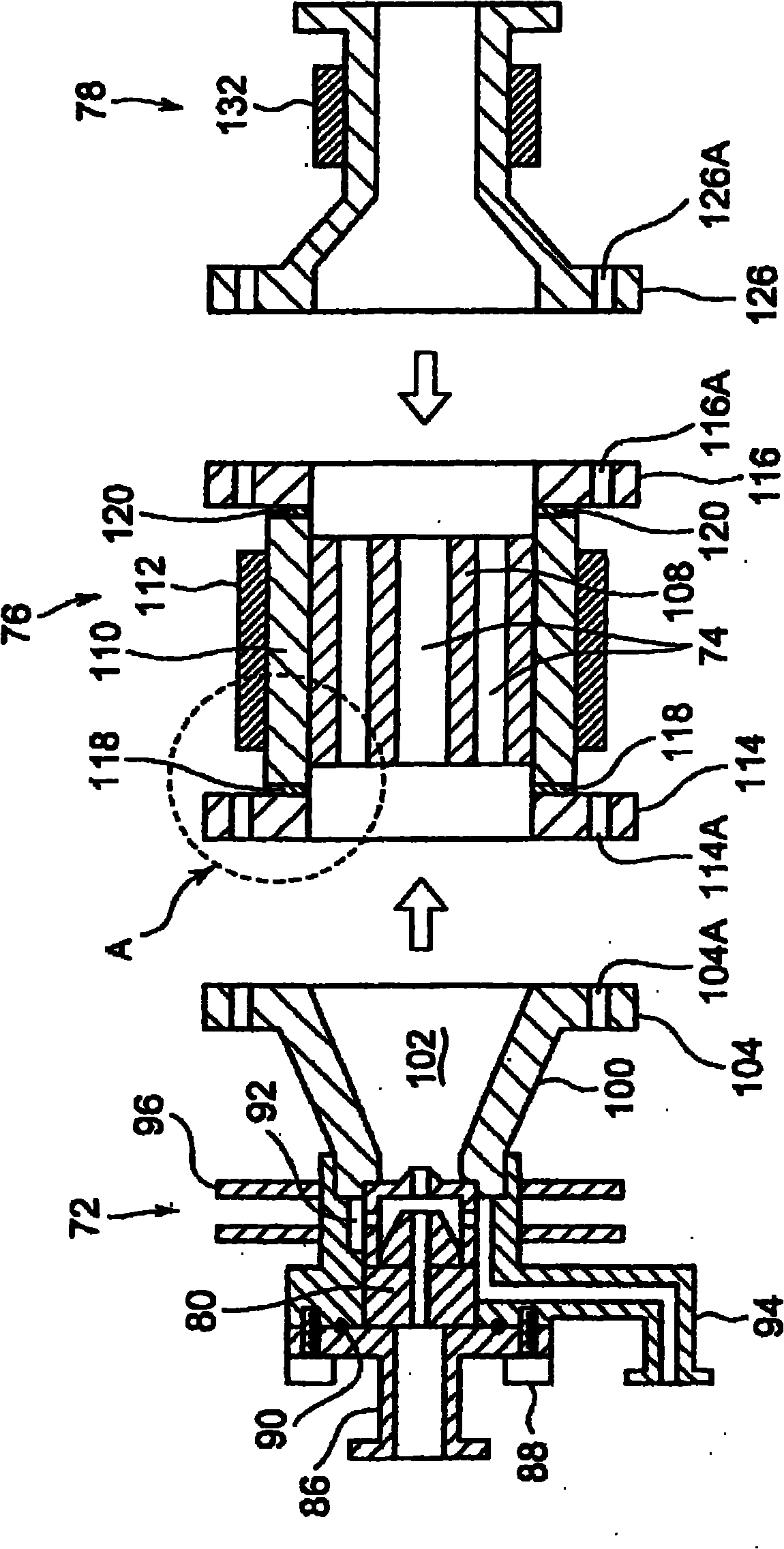

[0031] A preferred embodiment of the present invention will be described below with reference to the drawings. And in the following embodiments, for the use of tantalum pentaethoxide [Ta(OC 2 h 5 ) 5 ] (hereinafter also referred to as [PET]) as a liquid raw material, and using O 2 The gas is used as an oxidizing gas to describe an example in which a tantalum oxide film is formed on an object to be processed.

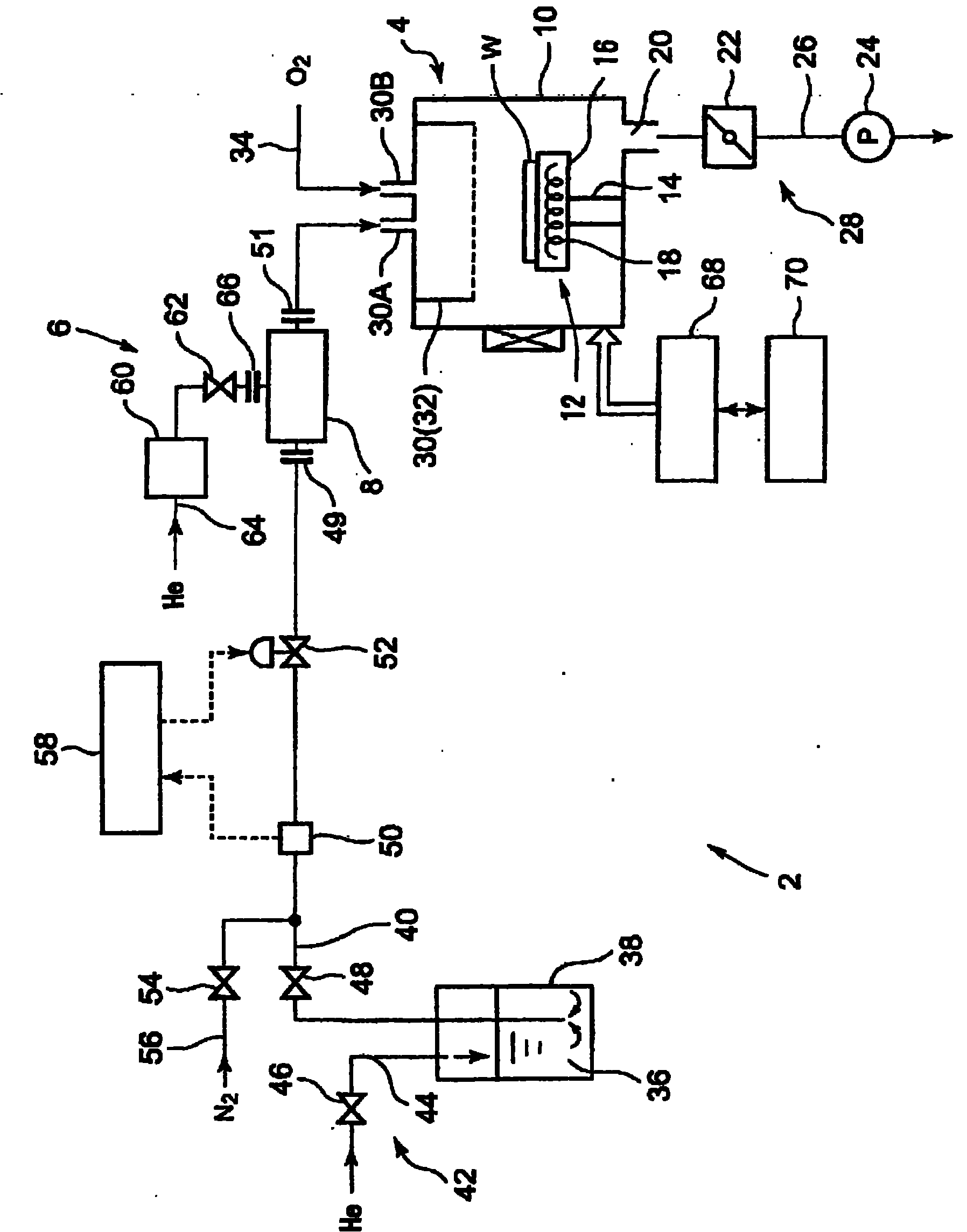

[0032] like figure 1 As shown, the film forming apparatus 2 of the present embodiment includes a film forming apparatus main body 4 as a gas use type, and a source gas supply system 6 for supplying a source gas to the film forming apparatus main body 4 . The film-forming apparatus main body 4 performs film-forming processing on a semiconductor wafer W as an object to be processed. A vaporizer 8 is provided in the raw material gas supply system 6 .

[0033] First, the film formation apparatus main body 4 will be described. like figure 1 As shown, the film forming ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com