Bonding agent applicable to copper foil cladding laminated board with full light shading performance

A technology of copper-clad laminates and adhesives, which is applied in the field of electronic information, can solve problems such as accelerating product penetration, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Additive formula (by weight share):

[0047] Nigrosine Silica powder Acetone

[0048] 11 45 45

[0049] 2) Adhesive formula (by weight):

[0050] Resin Dicyandiamide Dimethylimidazole Dimethylformamide Additive

[0051] 125 2.5 0.2 30 25

[0052] 3) Glue drying:

[0053] Oven temperature setting: 150-210°C,

[0054] Prepreg gluing speed: 12-15m / min.

[0055] 4) Prepreg control parameters:

[0056] Gel time: 115sec Epoxy resin content: 42% (refers to the mass percentage of epoxy resin in the prepreg)

[0057] Resin fluidity: 20.5% Volatile matter: 0.25%

[0058] 5) Number of layers of sheet metal arrangement: 8 pieces of 7628 prepreg (1.6mm)

[0059] 6) Platen parameters:

[0060] Vacuum: -0.097MPa,

[0061] Pressure: 300-450psi,

[0062] Hot plate temperature: 135-220°C,

[0063] Curing time: 50min.

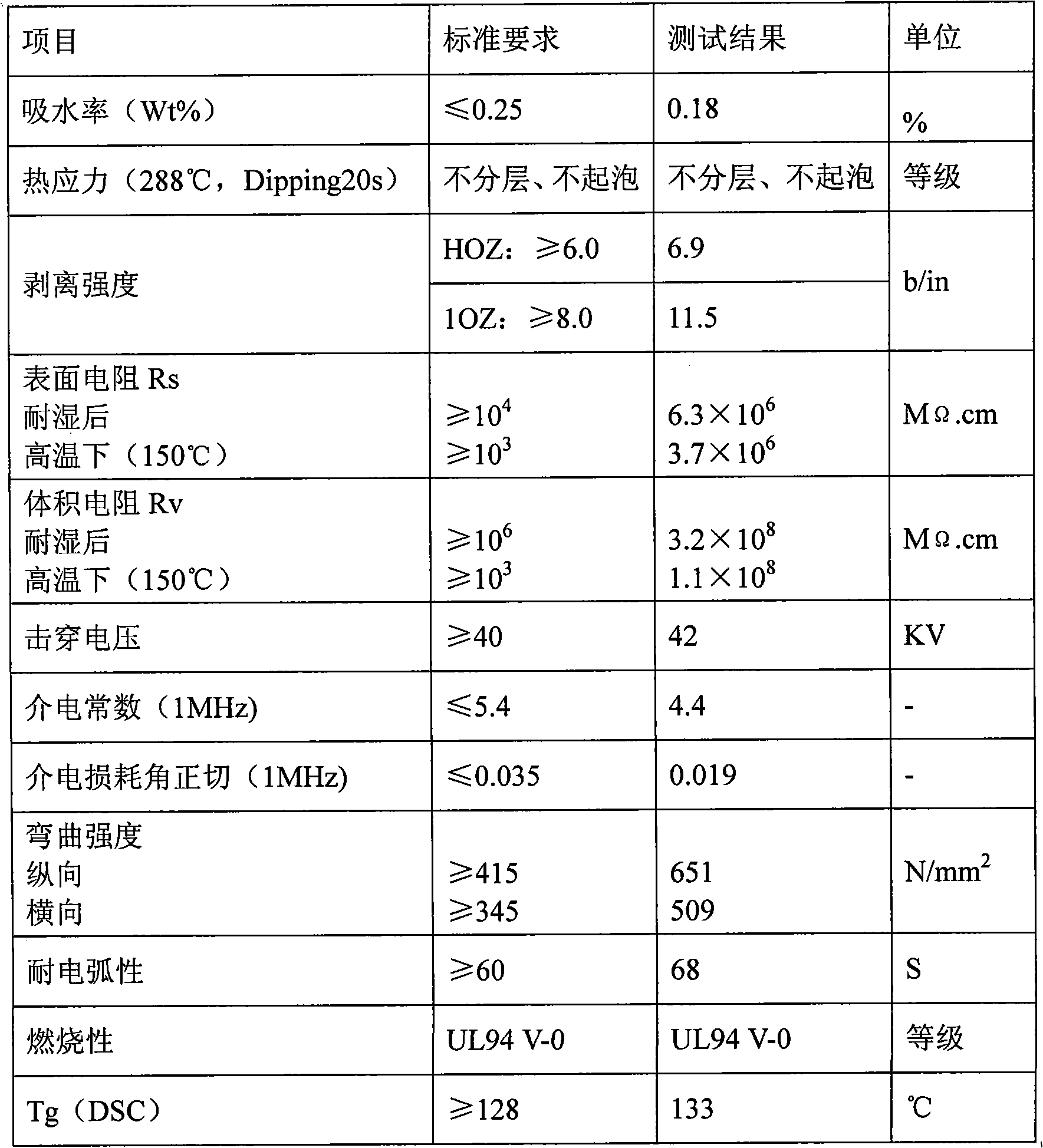

[0064] 7) Product substrate performance parameters

[0065]

Embodiment 2

[0067] 1) Additive formula (by weight share):

[0068] Nigrosine Silica powder Acetone

[0069] 12 45 45

[0070] 2) Glue mixing formula (by weight):

[0071] Resin Dicyandiamide Dimethylimidazole Dimethylformamide Additive

[0072]125 2.5 0.2 35 20

[0073] 3) Glue drying:

[0074] Oven temperature setting: 150-210°C,

[0075] Prepreg gluing speed: 12-15m / min.

[0076] 4) Prepreg control parameters:

[0077] Gel time: 115sec Epoxy resin content: 45.0%

[0078] Resin fluidity: 20.5% Volatile matter: 0.25%

[0079] 5) Number of layers of sheet metal arrangement: 8 pieces of 7628 prepreg (1.6mm)

[0080] 6) Platen parameters:

[0081] Vacuum degree: -0.097Mpa,

[0082] Pressure: 300-450psi,

[0083] Hot plate temperature: 135-220°C,

[0084] Curing time: 50min.

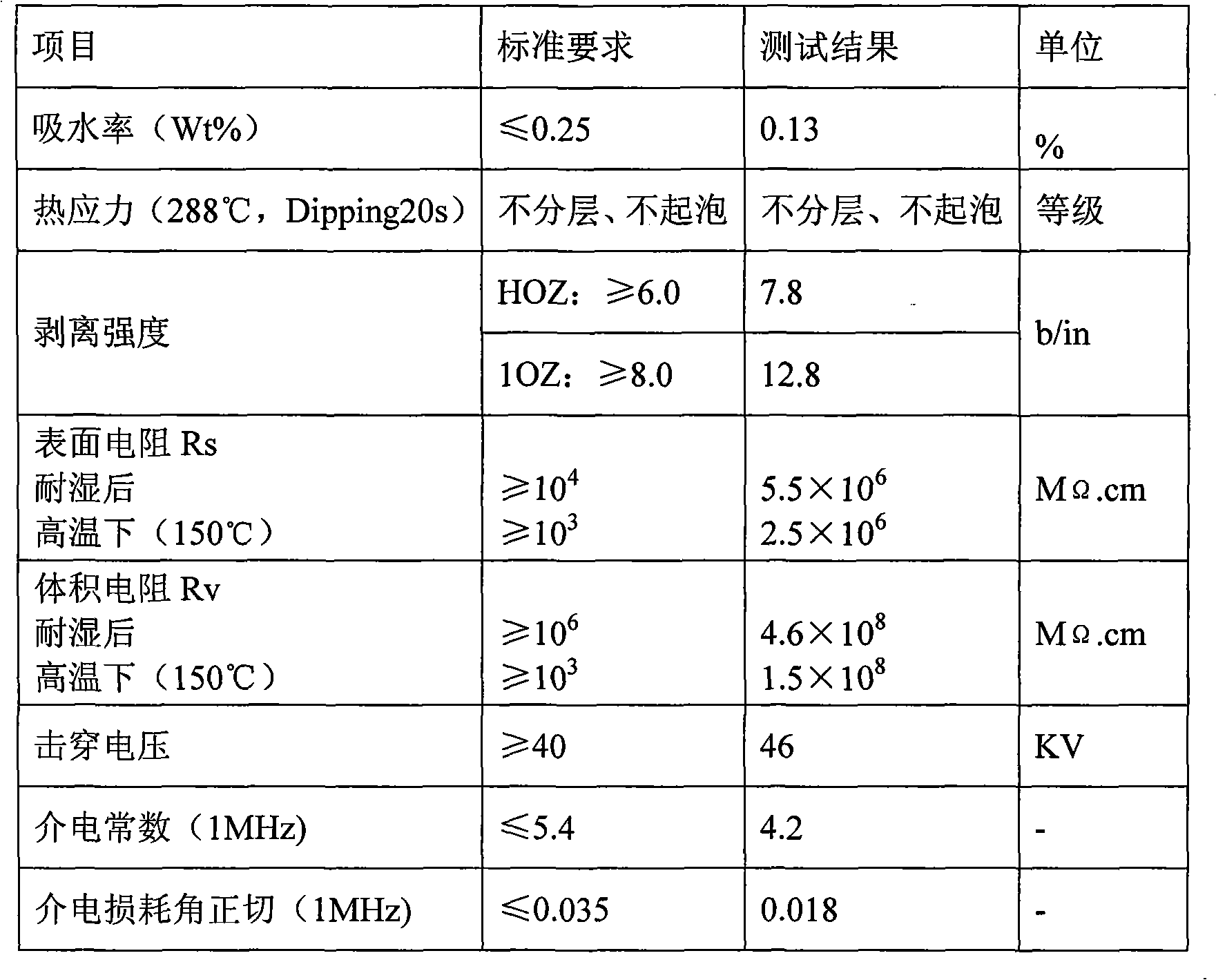

[0085] 7) Product substrate performance parameters

[0086]

[0087]

Embodiment 3

[0089] 1) Additive formula (by weight share):

[0090] Nigrosine Silica powder Acetone

[0091] 11 40 40

[0092] 2) Glue mixing formula (by weight):

[0093] Resin Dicyandiamide Dimethylimidazole Dimethylformamide Additive

[0094] 125 3 0.3 30 30

[0095] 3) Glue drying:

[0096] Oven temperature setting: 150-210°C,

[0097] Prepreg gluing speed: 12-15m / min.

[0098] 4) Prepreg control parameters:

[0099] Gel time: 115sec Epoxy resin content: 45.0%

[0100] Resin fluidity: 20.5% Volatile matter: 0.25%

[0101] 5) Number of layers of sheet metal arrangement: 8 pieces of 7628 prepreg (1.6mm)

[0102] 6) Platen parameters:

[0103] Vacuum degree: -0.097Mpa,

[0104] Pressure: 300-450psi,

[0105] Hot plate temperature: 135-220°C,

[0106] Curing time: 50min.

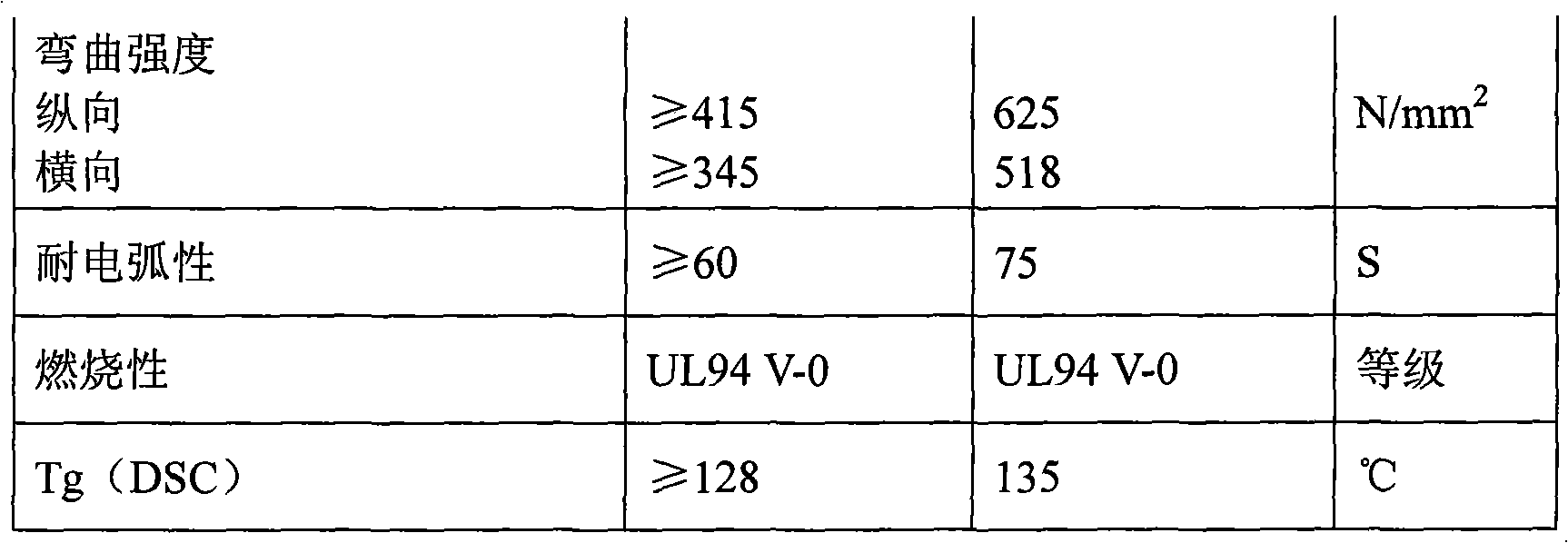

[0107] 7) Product substrate performance parameters

[0108]

[0109]

[0110] The epoxy glass cloth-based copper clad laminate substrate has a light transmittance of <0.1% in the visible light region...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com