Silicate yellow longpersistent phosphor and preparation method thereof

A phosphor and long afterglow technology, applied in the field of materials, can solve the problems of not long enough afterglow time, not meeting the needs of practical applications, etc., and achieve the effects of simple preparation method, improved afterglow time, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

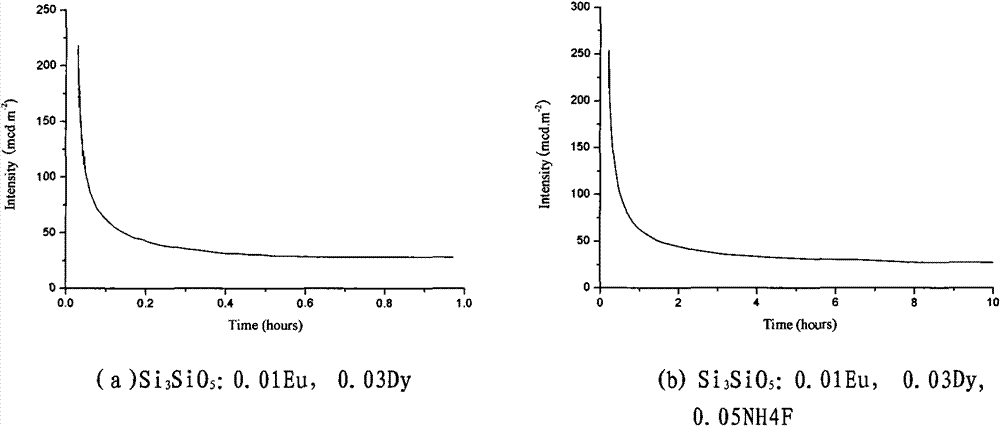

[0016] Preparation of Sr 2.96 SiO 5 :0.01Eu, 0.01Dy, 0.05NH 4 F, accurately weigh SrCO according to the chemical dosage ratio 3 4.3698g, SiO 2 0.6008g, Eu 2 o 3 0.0176g, Dy 2 o 3 0.0186g, NH 4 F0.0185g, after grinding the above raw materials evenly, put them into a corundum crucible, compact and cover, put the cover down into a large crucible with carbon powder, bury the corundum crucible with carbon powder, and then put the large crucible Covered and placed in a high-temperature furnace, calcined at 1200°C-1350°C for 6 hours, and cooled to room temperature to obtain Sr 2.96 SiO 5 :0.01Eu, 0.01Dy, 0.05NH 4 F yellow long afterglow phosphor, the excitation source is removed after ultraviolet light excitation, and the afterglow can be observed by human eyes for more than 7 hours in a dark room.

Embodiment 2

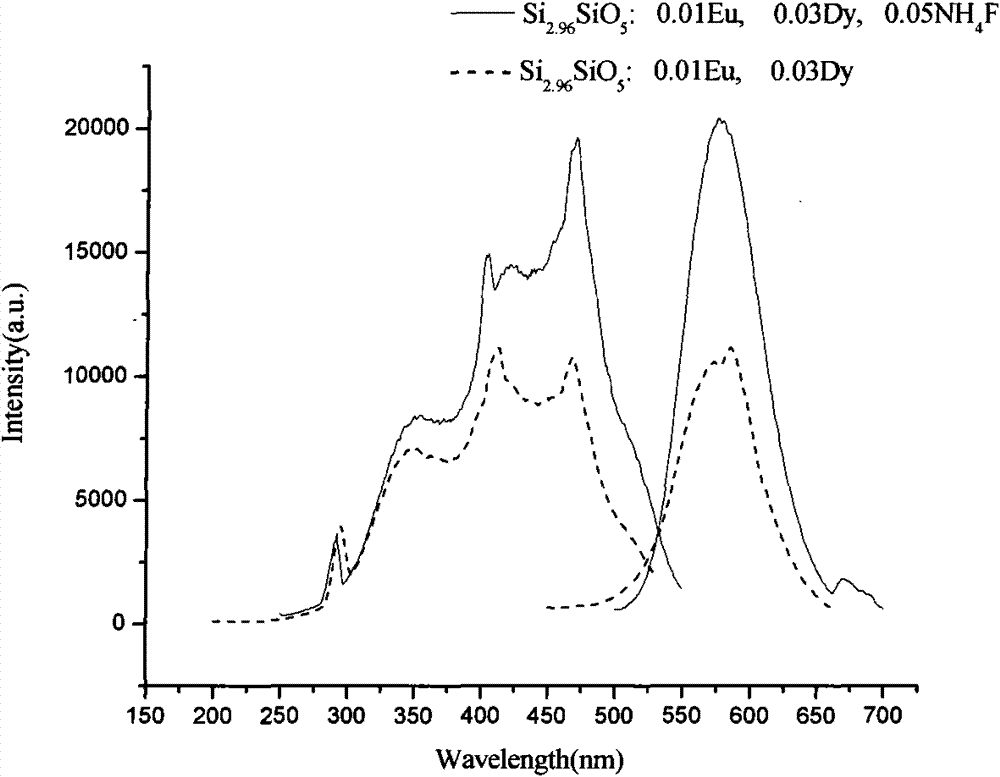

[0018] Preparation of Sr 2.96 SiO 5 :0.01Eu, 0.03Dy, 0.05NH 4 F, accurately weigh SrCO according to the chemical dosage ratio 3 4.3698g, SiO 2 0.6008g, Eu 2 o 3 0.0176g, Dy 2 o 3 0.0559g, NH 4 F0.0185g, after grinding the above raw materials evenly, put them into a corundum crucible, compact and cover, put the cover down into a large crucible with carbon powder, bury the corundum crucible with carbon powder, and then put the large crucible Covered and placed in a high-temperature furnace, calcined at 1200°C-1350°C for 6 hours, and cooled to room temperature to obtain Sr 2.96 SiO 5 :0.01Eu, 0.03Dy, 0.05NH 4 F yellow long afterglow phosphor, the excitation source is removed after ultraviolet light excitation, and the afterglow can be observed by human eyes for more than 10 hours in a dark room.

Embodiment 3

[0020] Preparation of Sr 2.96 SiO 5 :0.01Eu, 0.03Dy, 0.05BaF 2 , accurately weigh SrCO according to the stoichiometric ratio 3 4.3698g, SiO 2 0.6008g, Eu 2 o 3 0.0176g, Dy 2 o 3 0.0559g, BaF 2 0.0877g, after grinding the above raw materials evenly, put them into a corundum crucible, compact and cover, put the cover down into a large crucible with carbon powder, bury the corundum crucible with carbon powder, and then add the large crucible Put the cover into a high-temperature furnace, calcinate at 1200°C-1350°C for 6 hours, and cool to room temperature to obtain Sr 2.96 SiO 5 :0.01Eu, 0.03Dy, 0.05BaF 2 Yellow long afterglow phosphor, the excitation source is removed after ultraviolet light excitation, and the afterglow can be observed by human eyes for more than 12 hours in a dark room.

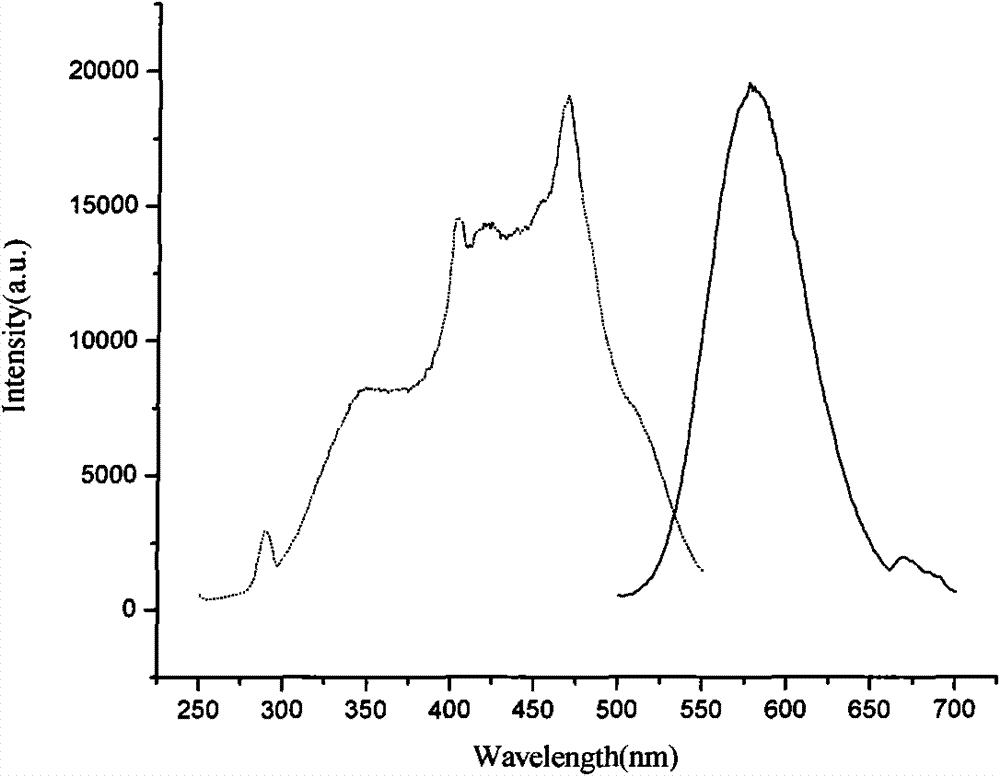

[0021] image 3 Shown as Sr 2.96 SiO 5 :0.01Eu, 0.03Dy, 0.05BaF 2 Excitation and emission spectra of phosphors. Figure 4 Shown as Sr 2.96 SiO 5 :0.01Eu, 0.03Dy, 0.05BaF 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com