Device for removing zinc dross in galvanized wire zinc pot

A cleaning device and galvanizing line technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems of toxic dust volatilization of zinc liquid, unsafe factors, splashing of zinc liquid, etc., and reduce labor costs The effect of improving strength, improving product quality, and eliminating unsafe hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

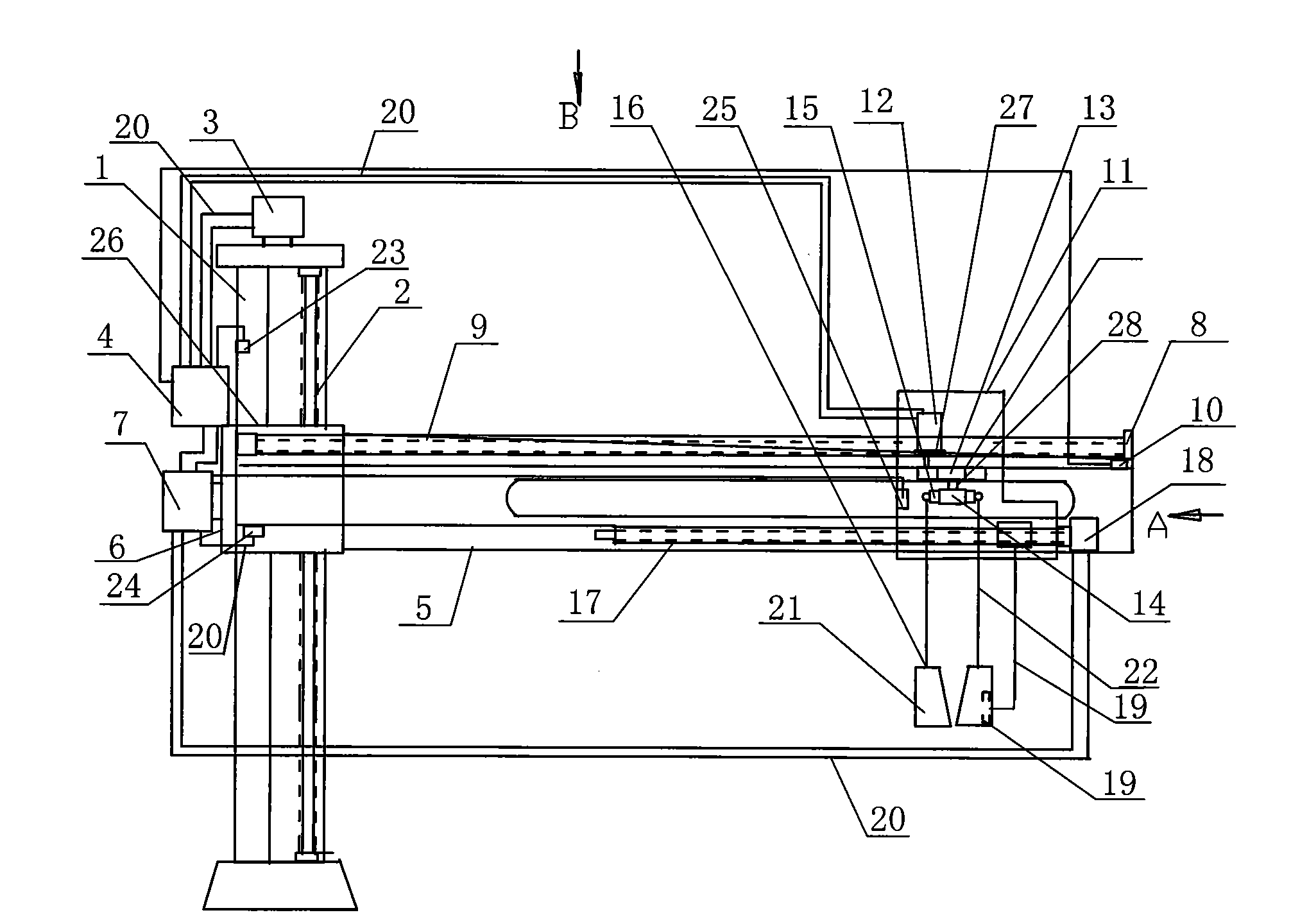

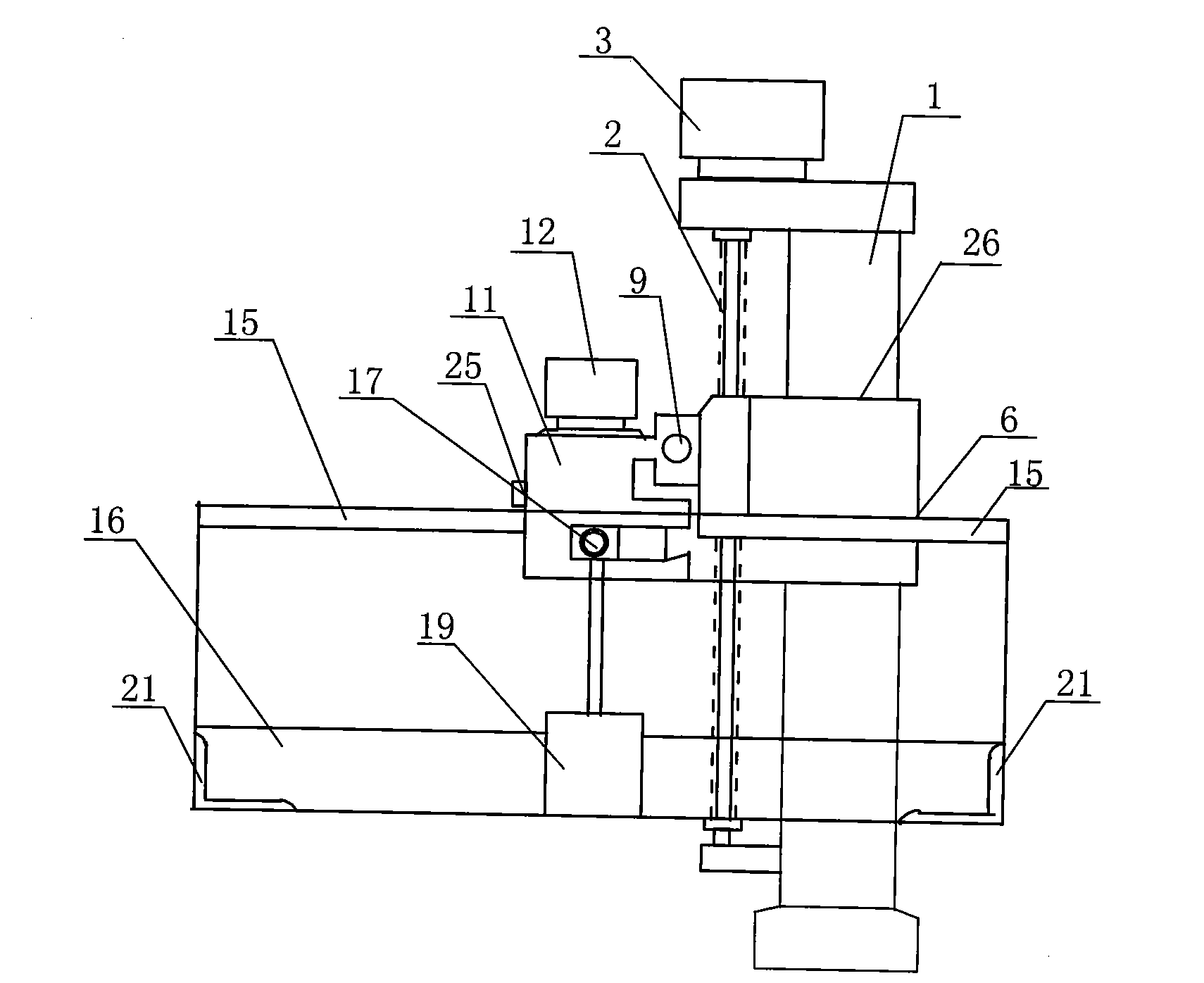

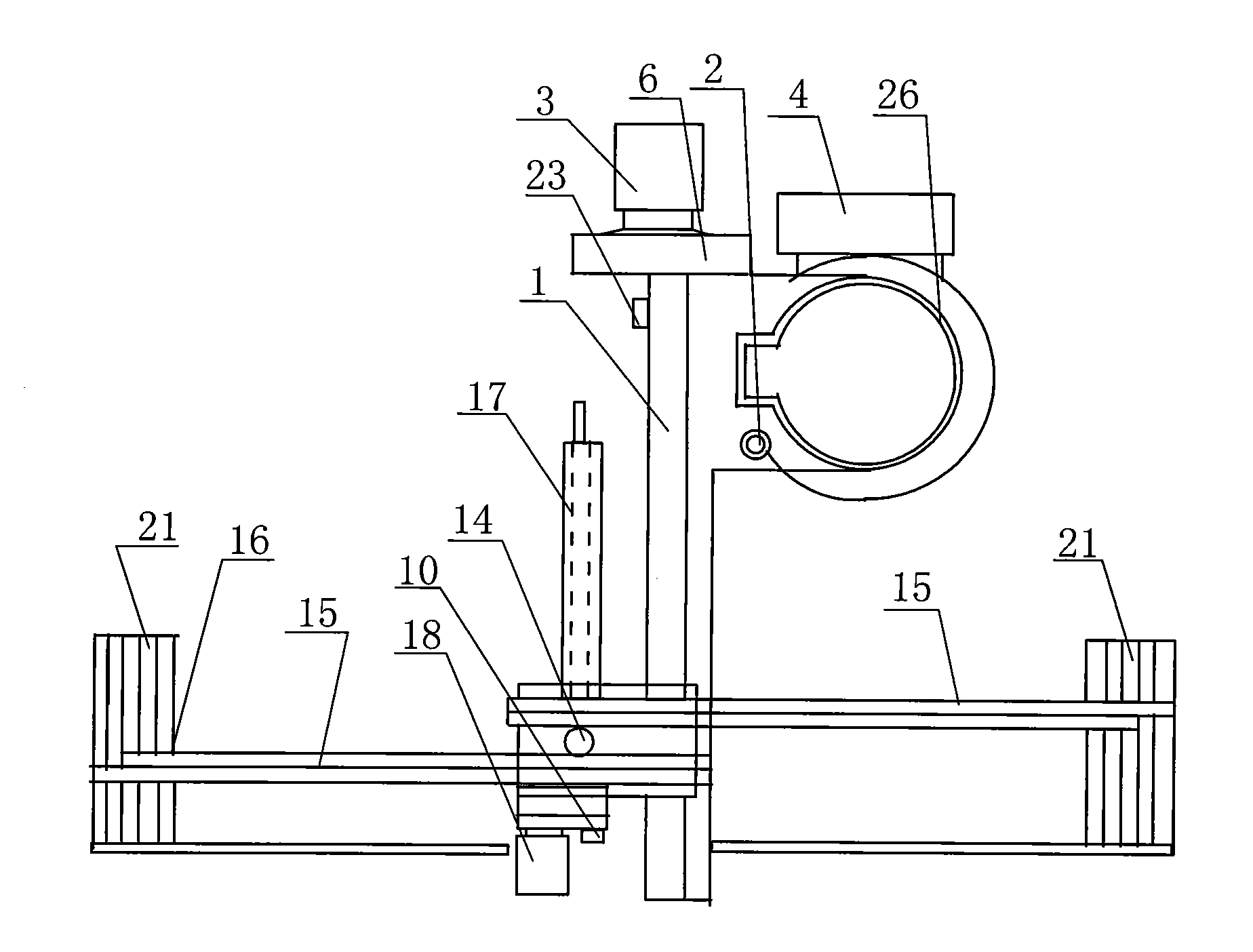

[0021] A device for removing zinc slag in a galvanizing pot of a galvanizing line, which includes a pillar 1, a guide screw 2 connected to the pillar 1, a lifting motor 3, a cantilever structure, a slag removing mechanism, a PLC controller 4 and a slag pushing mechanism;

[0022] Connect the pillar 1 to the ground through anchor bolts or bases or pouring cement, and connect the processed guide screw 2 with the matching internal thread processed on the pillar 1 through the thread; install it at the position set on the pillar 1 The upper limiter 23 of the cantilever fixed end 6; the lifting motor 3 is installed on the upper end surface of the pillar 1;

[0023] Cantilever mechanism: process the cantilever fixed end 6, and longitudinally process the lifting hole 26 matching the diameter of the pillar 1; process the cantilever beam 5, and connect the cantilever beam 5 to the cantilever fixed end 6 by welding; at the cantilever fixed end The end of 6 is connected with the cantileve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com