Method for constructing maintainable tunnel waterproof system

A construction method and tunnel technology, which is applied in tunnels, tunnel linings, earthwork drilling, etc., can solve problems such as large damage to tunnel structures, unsatisfactory waterproof effects, and difficulty in guaranteeing treatment effects, and achieve low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

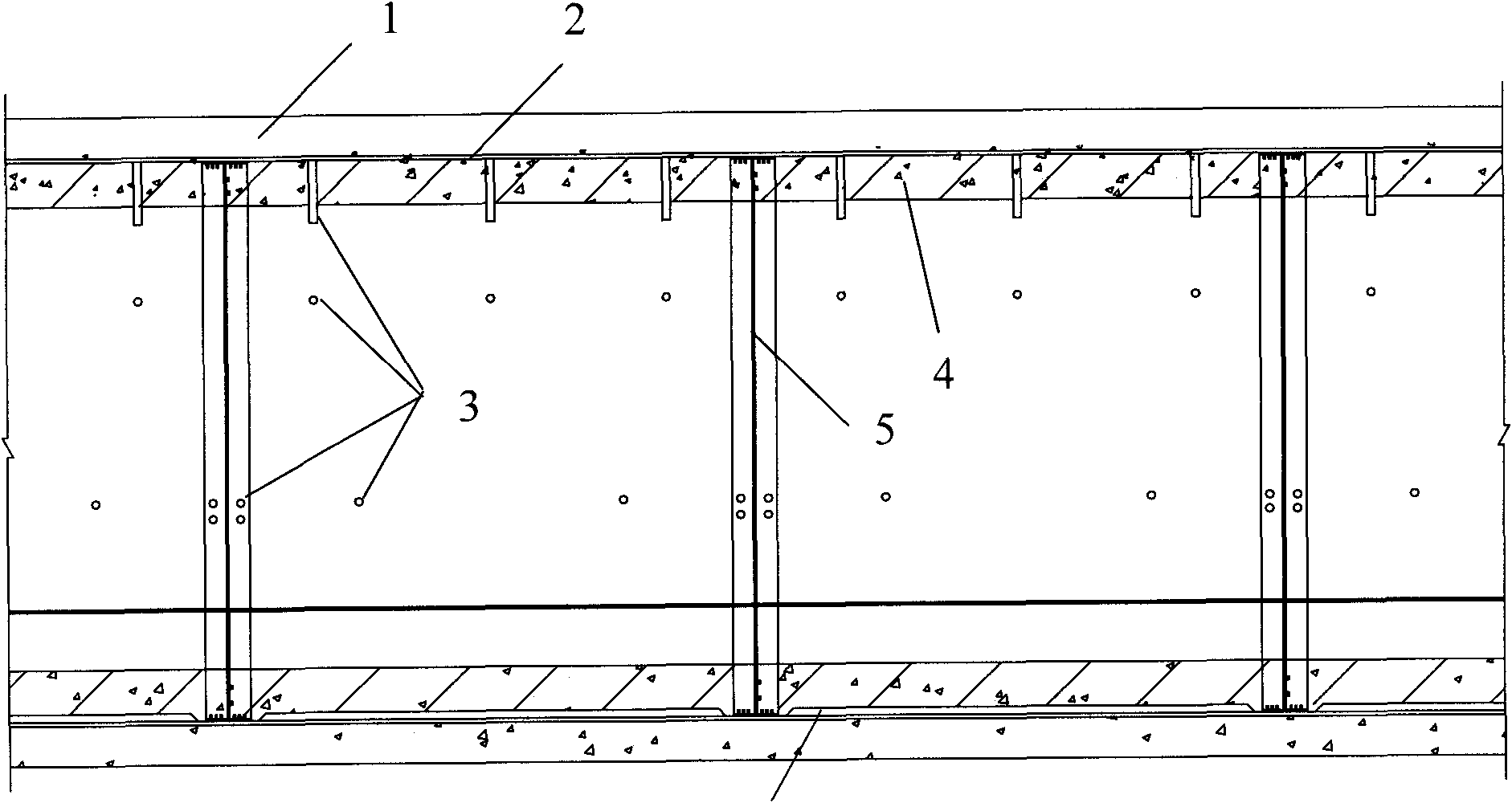

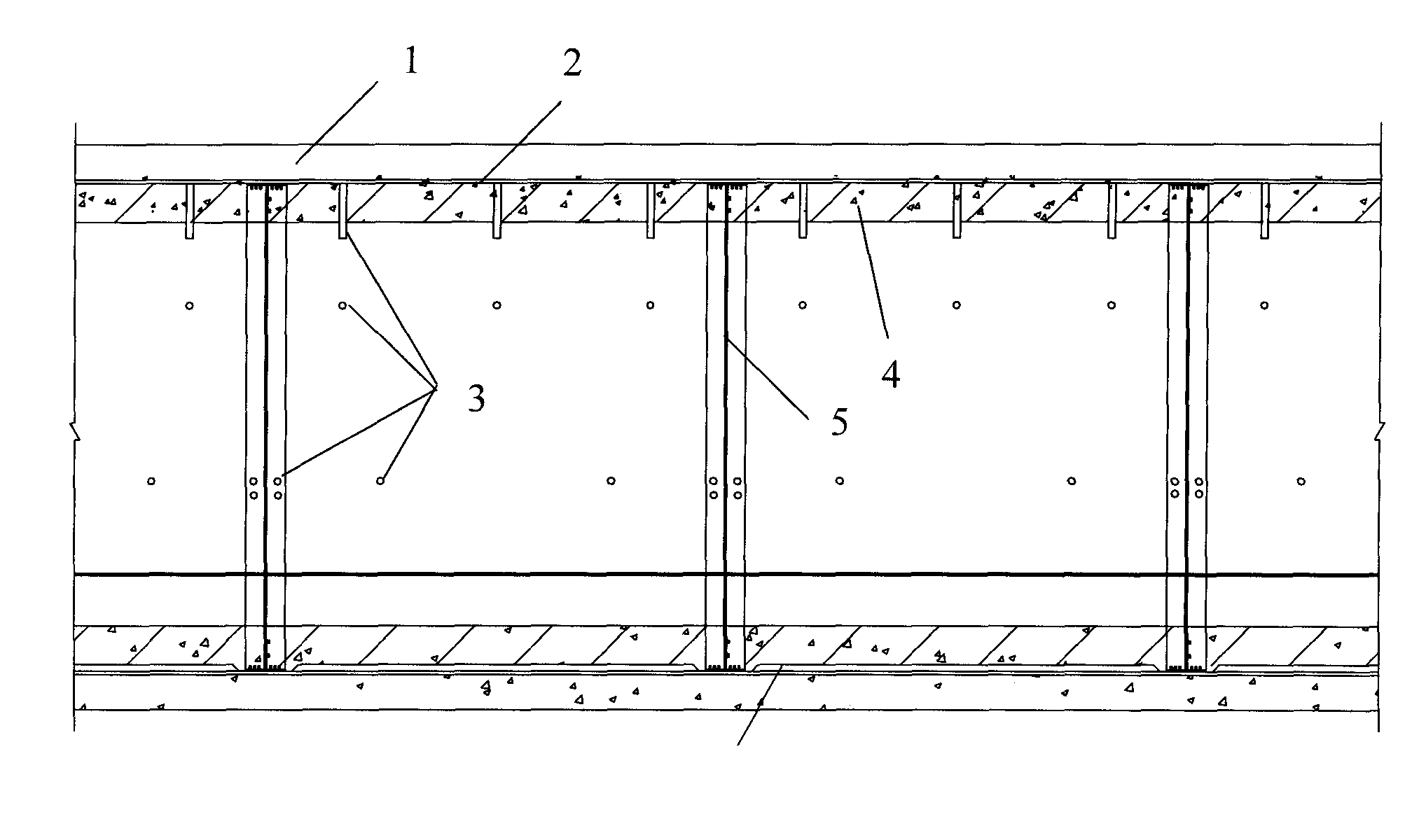

[0014] like figure 1 As shown, the maintainable tunnel waterproof system construction method provided by the present invention includes the following steps in order:

[0015] 1) First, spray a layer of shotcrete layer 1 on the surrounding rock of the tunnel using traditional methods, lay a waterproof layer 2 with a buffer function, and then use the lining of each mold as a waterproof partition, in the middle of each partition and adjacent partitions A plurality of grouting pipes 3 are pre-embedded outside the waterproof layer 2 in the radial direction at the adjacent parts;

[0016] 2) Then pour a layer of molded concrete layer 4 outside the waterproof layer 2 in each partition, thereby forming a circumferential construction joint 5 between the molded concrete layers 4 of adjacent partitions, and simultaneously make all the grouting pipes The grouting nozzle of 3 is located outside the molded concrete layer 4;

[0017] 3) Finally, the above-mentioned circumferential construc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com