Plate-type concentrated material distributing valve device

A technology for distributing valve and thick material, applied in valve devices, multi-port valves, engine components, etc., can solve the problems of complex structure and unreliable sealing of the two-way thick material reversing valve, and achieve easy and reliable sealing and easy construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in combination with specific embodiments.

[0032] Unless otherwise indicated, the quantities mentioned below can be changed according to needs, for example, the numbers of tie rods, cutting rings, rubber springs, etc. can be changed according to needs.

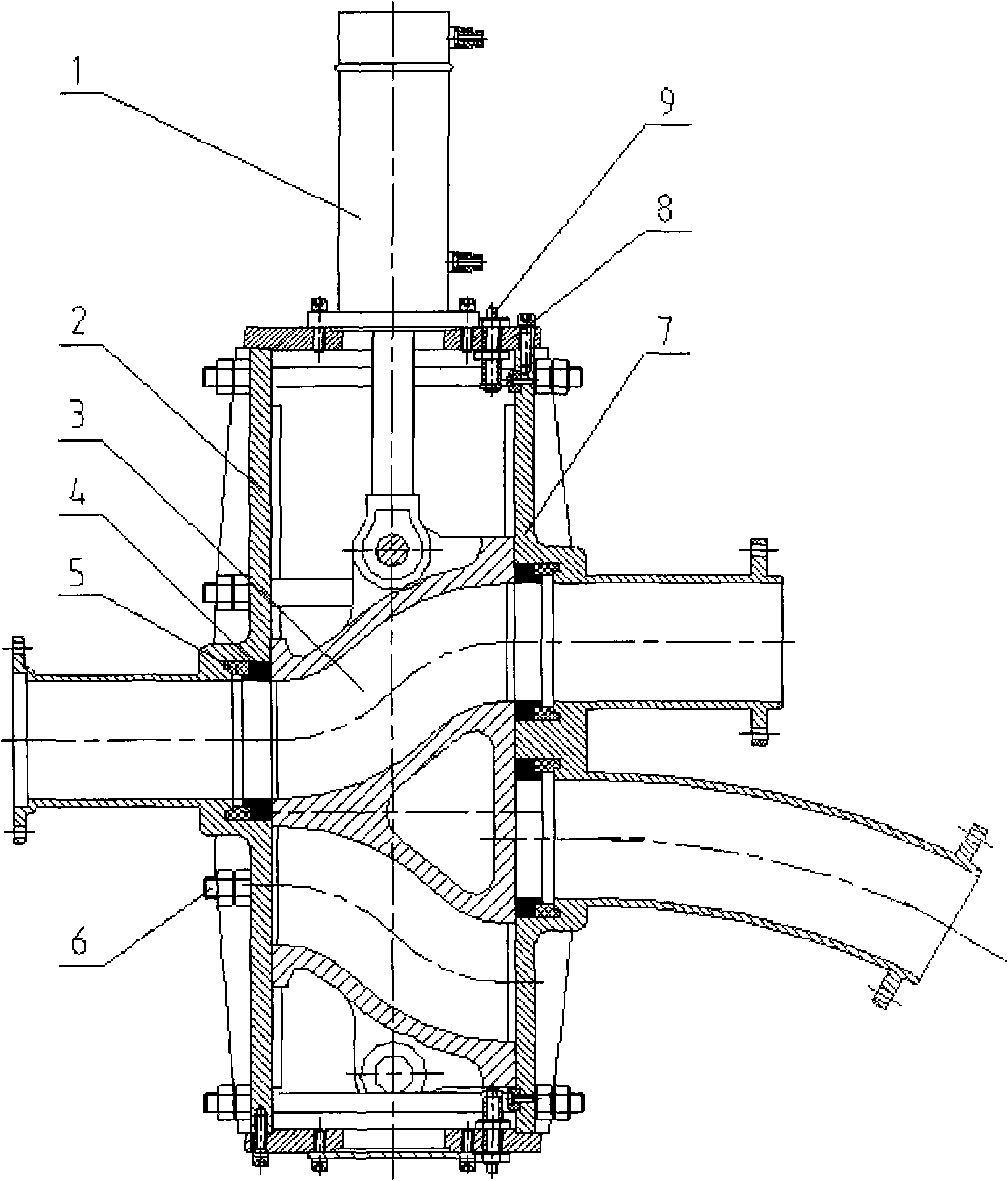

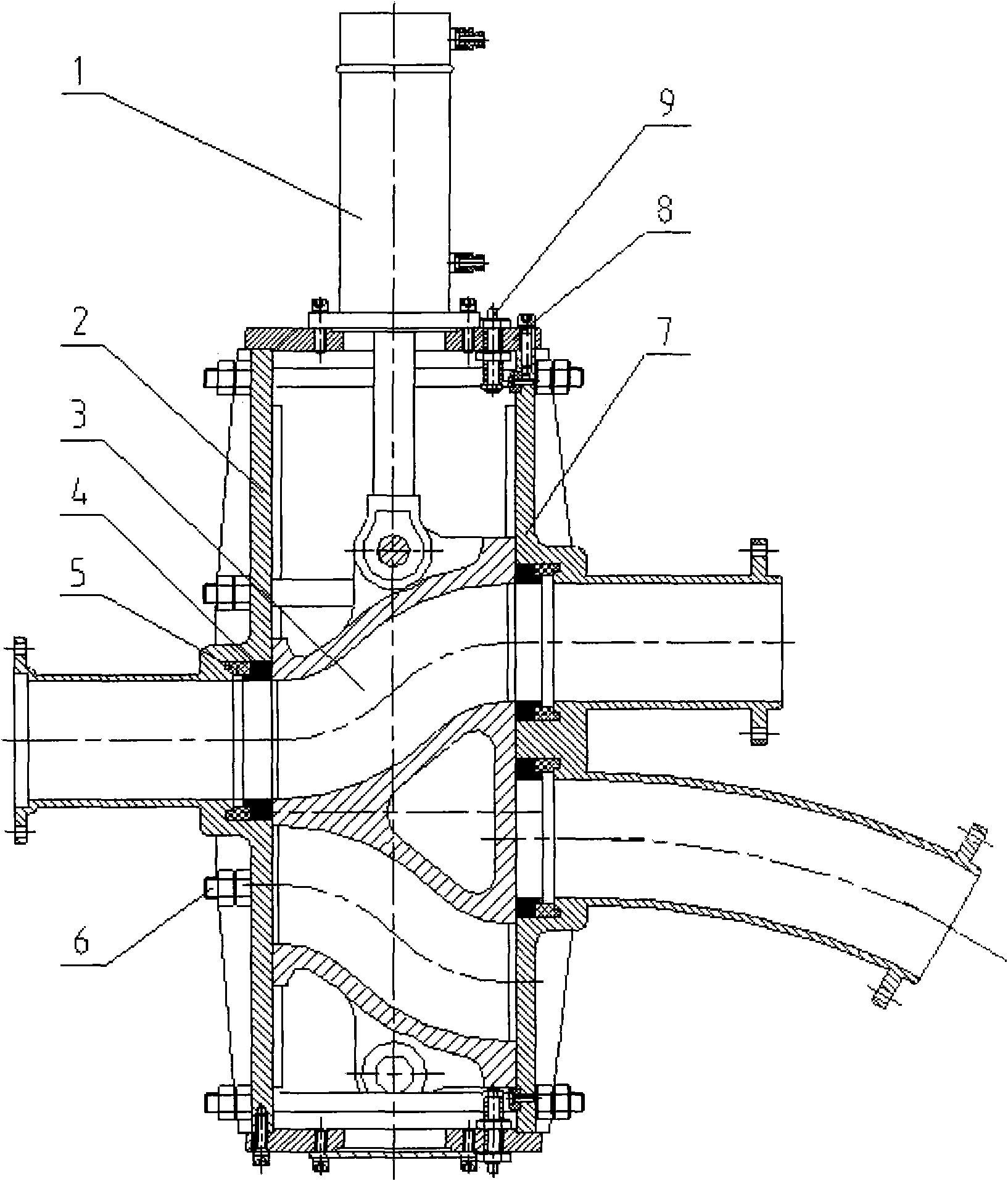

[0033] According to an embodiment of the present invention, the plate-type concentrated material distribution valve device is used to connect a delivery main pipe and one of two branch pipes during the pipeline transportation of concentrated materials, such as figure 1 As mentioned above, the plate-type concentrated material distribution valve device includes a hydraulic cylinder 1, a single tube plate 2, a valve body 3, three cutting rings 4, three rubber springs 5, eight pull rods 6, a double tube plate 7, and two seat plates 8 and proximity switch 9. The single tube sheet 2 has a header pipe, the header pipe has a first end and a second end, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com