Gas and combustion air mixing device of combustion system

A combustion system and combustion-supporting air technology, applied in burners, combustion methods, combustion types, etc., can solve the problems of slow flame propagation, failure to achieve energy conservation and environmental protection, and insufficient combustion of gas, and improve the propagation speed and combustion temperature. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

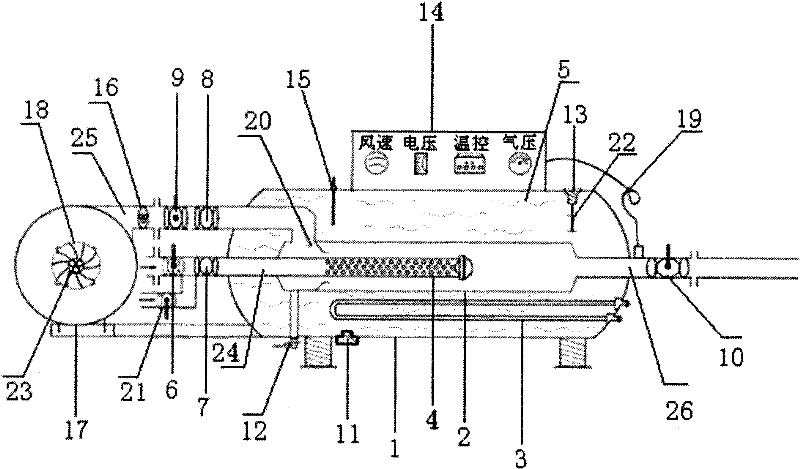

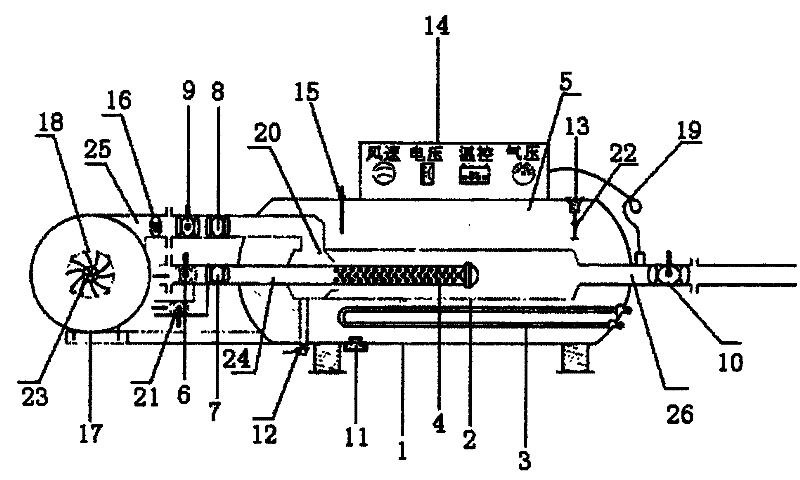

[0020] The mixing device of gas and combustion-supporting air in the combustion system of this embodiment includes a main body chamber 1 carrying a heat-conducting medium 5, an oxygen gasification mixing chamber 2 for mixing oxygen and fuel gas is installed in the main body chamber 1, and an oxygen gasification mixing chamber 2 There is a gas spray pipe 4 inside, and the gas spray pipe 4 is externally connected to a gas flow control device. One end of the oxygen gasification mixing chamber 2 is connected to a mixed gas output pipeline 26, and the other end is connected to a pipeline for preventing the mixed gas from backflowing to form pressure and blocking oxygen intake. The check throat pipe 20 is externally connected with an oxygen-enriched flow control device; the gas flow control device includes a main gas supply pipe 24 communicating with the gas spray pipe 4, and the main gas supply pipe 24 is internally equipped with a The main gas control solenoid valve 6 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com