Vehicle permanent magnetic synchronous motor and stator iron core capable of weakening magnetic resistance moment

A technology for permanent magnet synchronous motors and stator cores, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit stationary components, magnetic circuit shape/style/structure, etc. Accuracy, high-speed and stable operation, system over-current protection device does not have enough time to act, unable to prevent the rise of the armature reaction flux, etc., to improve the rapid response capability, facilitate high-speed operation, and prevent the rise of the armature reaction flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

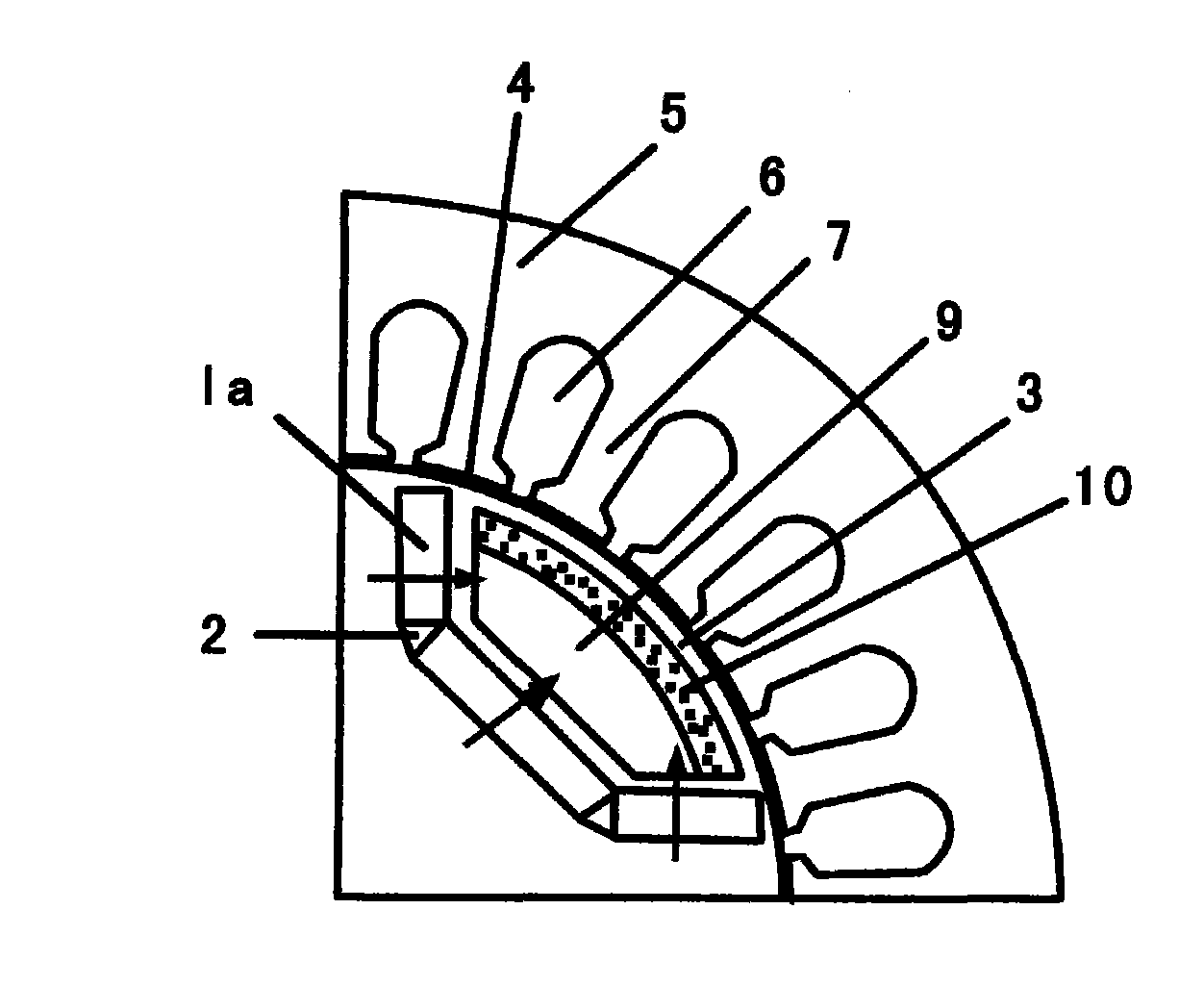

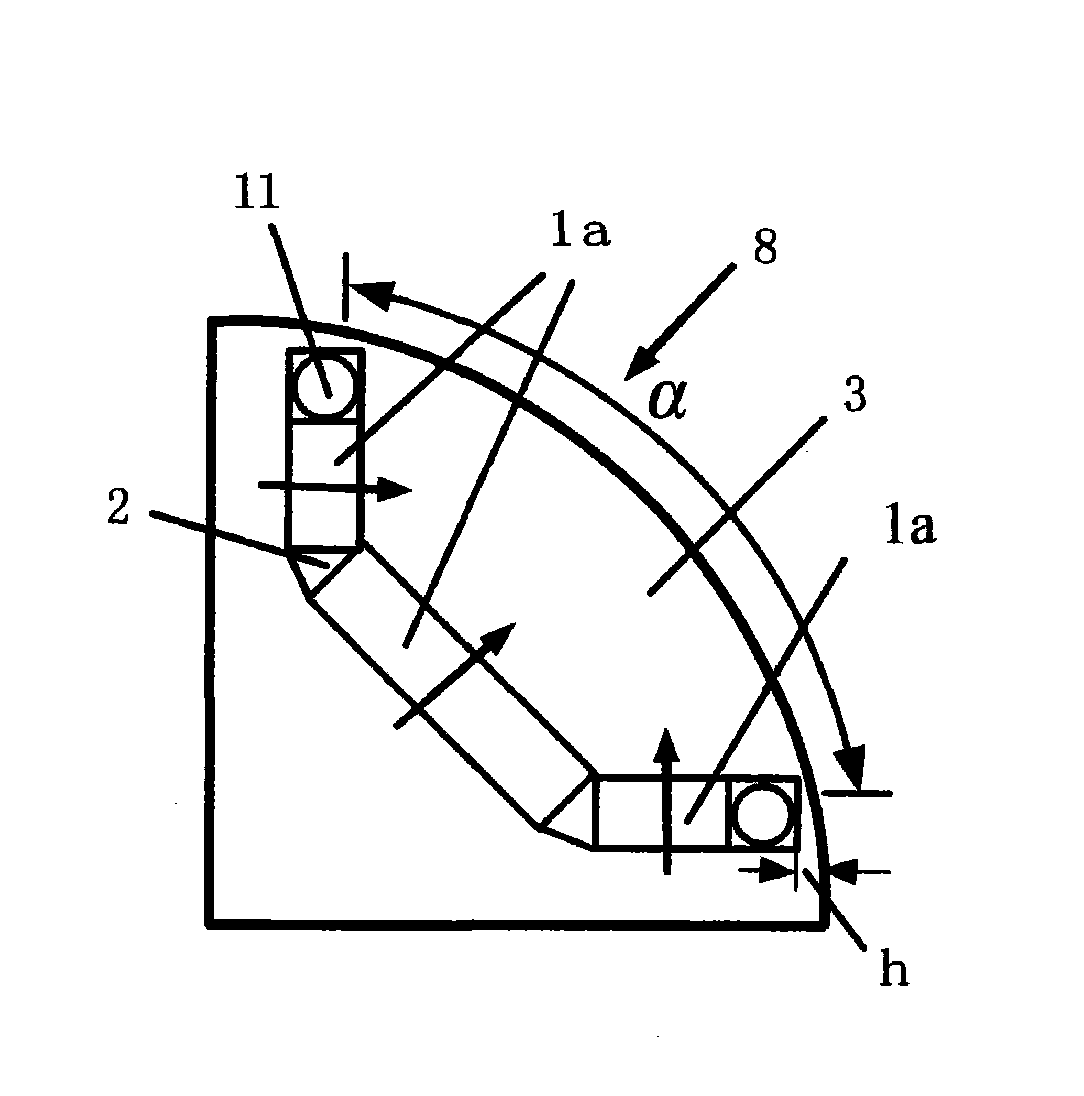

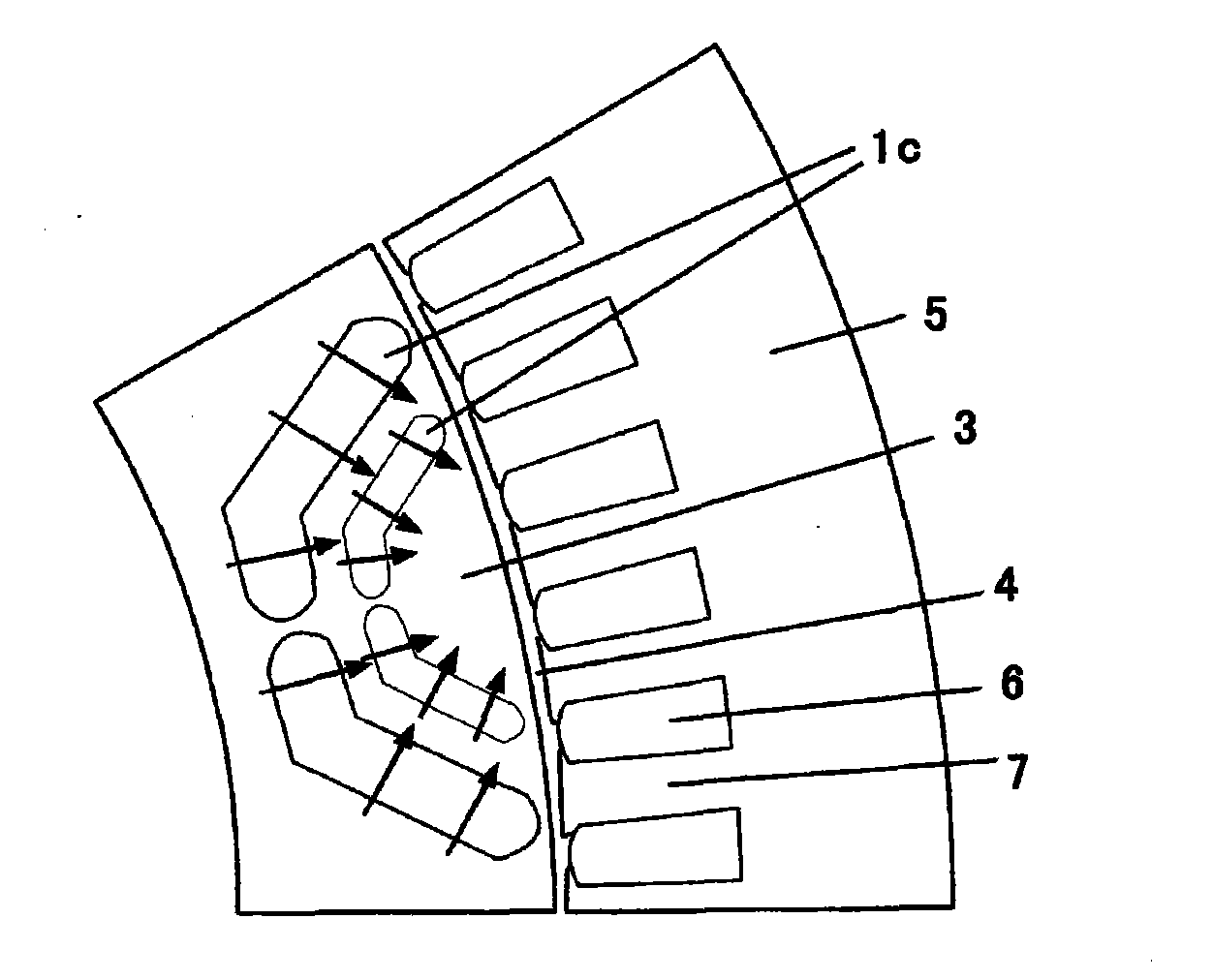

[0034] Such as figure 1 As shown, the present invention provides a permanent magnet synchronous motor for vehicles. A stator and a rotor are installed inside the casing. The stator is composed of a stator core fixed on the inner wall of the casing and a stator winding. The stator core includes a stator yoke 5 , stator slots 6 and stator teeth 7, the rotor is composed of a rotating shaft and a rotor core, and radially magnetized magnetic steel is evenly inlaid in the circumferential direction inside the rotor core, and the magnetic steel and the pole shoes 3 on the outside form permanent magnetic poles, forming The last permanent magnet poles play the role of magnetic concentration, improvement of air gap magnetic field waveform, reduction of torque ripple, and suppression of static and dynamic armature reactions. The magnetic force lines emitted from the surface of the magnetic steel extend to the pole piece and converge at the center of the magnetic pole to form a magnetic po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com