Polymer gel structure and method for producing same

A gel structure, polymer technology, used in chemical instruments and methods, other household appliances, synthetic resin layered products, etc., can solve problems such as inability to maintain lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0066] An understanding of various aspects of the invention can be gained by illustrating the examples provided below, although the invention is not limited thereby.

example 1

[0067] Example 1: Preparation of polymer gel structures

[0068] Preparation of the first polymer component :

[0069] By mixing 10 g of acrylic acid (AAc, Wako Pure Chemical Industries, Ltd., Osaka, Japan), 20 g of distilled water, 0.4 g of NK Ester A-400 (Shin Nakamura Chemical Co., Ltd., Fukui, Japan) and 0.014 g of IRGACURE 2959 (Basel, Switzerland) A trade name of Ciba Specialty Chemicals Co., Ltd.) to prepare an aqueous solution of a UV-curable monomer (ie, the first monomer solution or the first solution). NK-Ester A-400 refers to the diacrylate ester of polyethylene glycol having an average molecular weight of about 400. IRGACURE 2959 refers to the photoinitiator 1-[4-(2-hydroxyethoxy)-phenyl]-2-hydroxy-2-methyl-1-propan-1-one for UV curing. Nitrogen (N 2 ) to sweep the first solution, and then apply it to the film-forming tool.

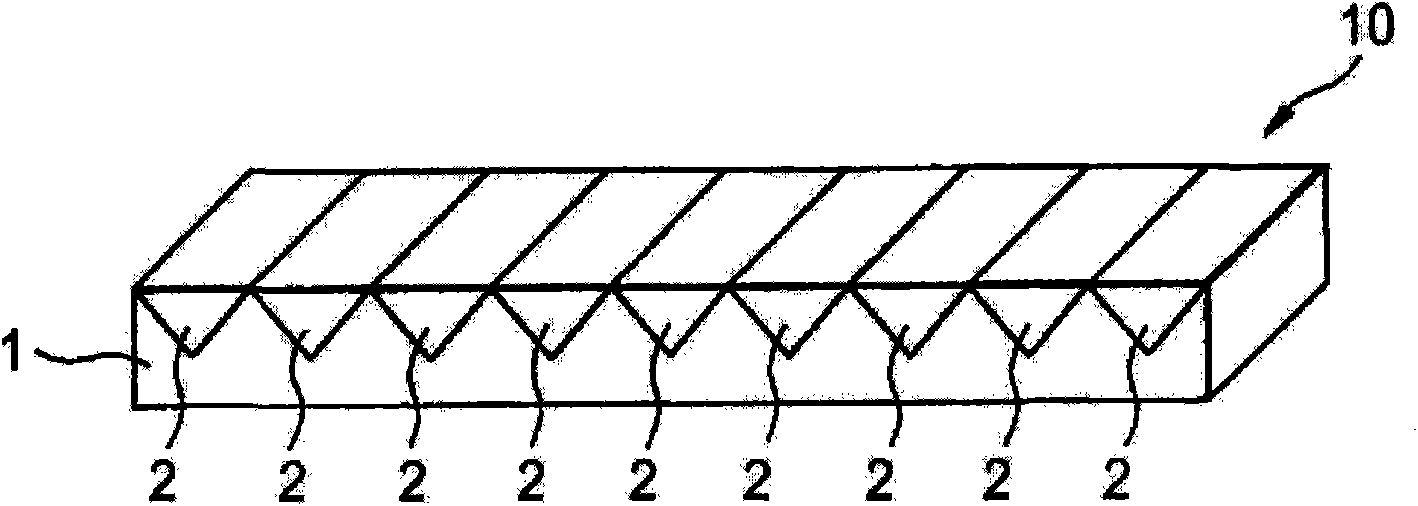

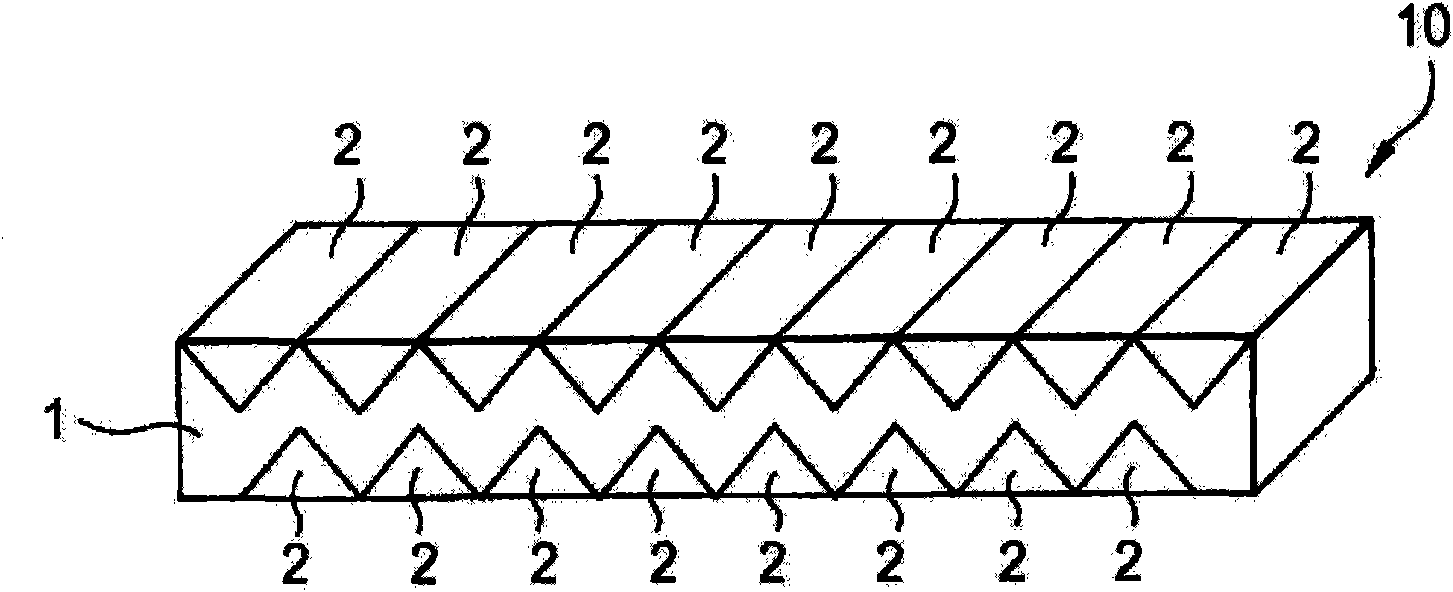

[0070] The film-forming tool is a pyramidal die made of polypropylene. The pyramid shape in the film-forming tool had a length of 1...

example 2

[0074] Example 2: Add polyethylene glycol

[0075] Preparation of the first polymer component :

[0076] By mixing 1.8 grams of 2-acrylamido-2-methylpropanesulfonic acid (AMPS, Toagosei Co., Ltd., Tokyo, Japan, Toagosei Co., Ltd.), 10.8 grams of distilled water, and 0.088 grams of N,N-methylenebisacrylamide ( MBAA, Wako Pure Chemical Industries, Ltd., Osaka, Japan) and 0.014 g of IRGACURE 2959 (trade name of Ciba Specialty Chemicals, Basel, Switzerland) were used to prepare an aqueous solution of UV-curable monomers. To increase the viscosity of the aqueous solution, 0.4 g of polyethylene glycol (PEG, average molecular weight = 500,000, Wako Pure Chemical Industries, Ltd., Osaka, Japan) was also added. use N 2 The second solution is purged with gas. The second solution was then coated onto a film forming tool, laminated to PET film, and UV treated as described in Example 1. The first polymer component was then removed from the film-forming tool, resulting in a first la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com