Method for preparing multilayer raised compound film

A composite film layer and film layer technology, which is applied in the direction of manufacturing microstructure devices, microstructure technology, microstructure devices, etc., to achieve the effects of improving preparation speed, reducing errors, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

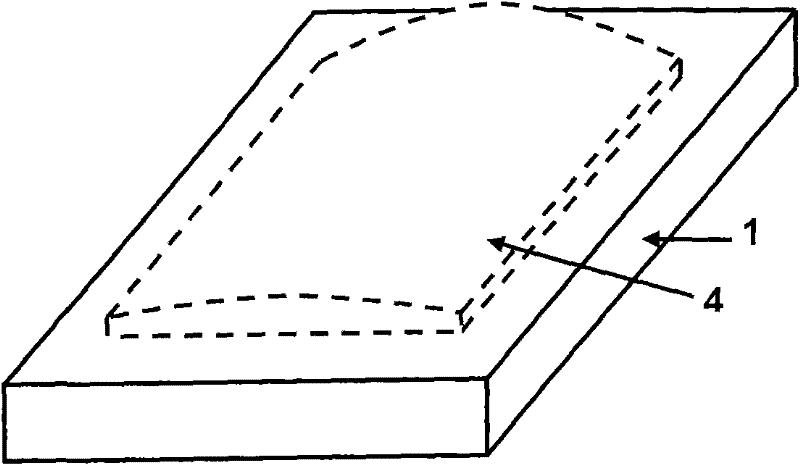

[0037] Embodiment 1 is to make a width of 8 microns and a length of 200 microns by the method of the present invention, which is composed of the first and third layers of silver and the second layer of silicon dioxide embossed structure film alternately. The manufacturing process is as follows:

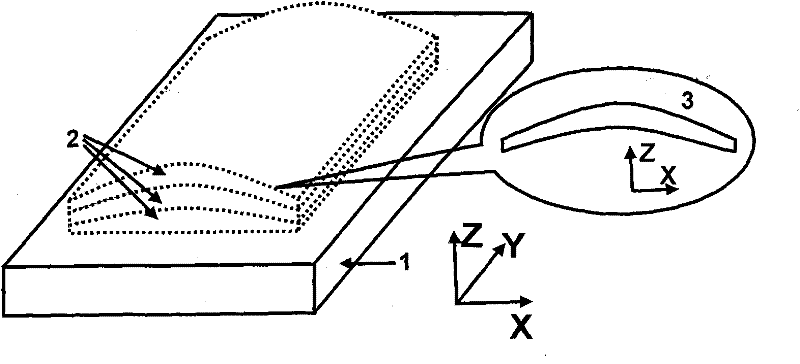

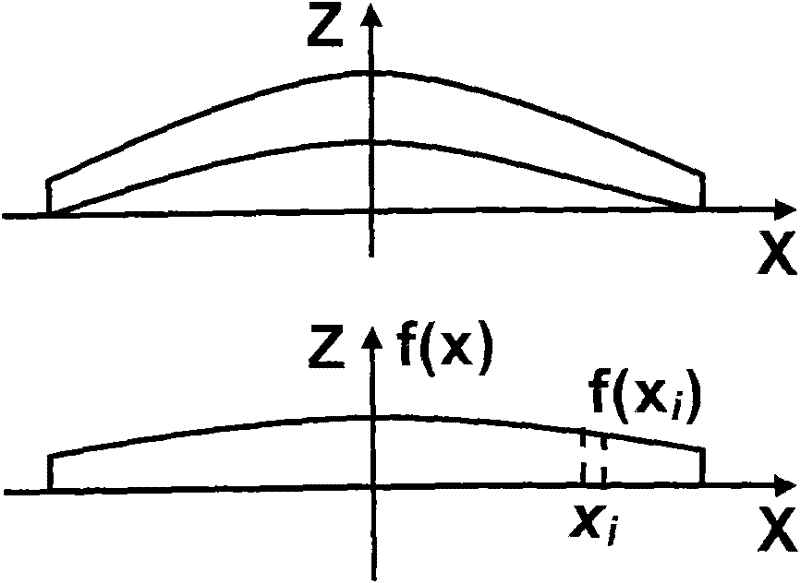

[0038] (1) As shown in Figure 1, the thickness distribution function of the film layer can be obtained by subtracting the function of the upper interface of any film layer of the super lens to be prepared by subtracting the function of the lower interface, so that the thickness of each film layer is obtained Distribution function;

[0039] Let the upper interface function of the i-th layer be f i (x), (i=1, 2, 3), where x is the moving direction of the mask, and the function of the interface on the substrate is f 0 (x)=0; the lower interface of the i-th film layer is the upper interface of the i-1th film layer, so the lower interface function of the i-th film layer and the upper inte...

Embodiment 2

[0047] Embodiment 2 is to make a SiO with a width of 20 microns and a length of 300 microns by the method of the present invention. 2 The two-layer optical lens composed of GaN and its production process is as follows:

[0048] (1) Subtracting its lower interface function from the upper interface function of any film layer of the super lens to be prepared can obtain the thickness distribution function of the film layer, so that the thickness distribution function of each layer film layer is obtained;

[0049] Let the upper interface function of the i-th layer be f i (x), (i=1, 2), where x is the moving direction of the mask, and the function of the interface on the substrate is f 0 (x)=0; the lower interface of the i-th film layer is the upper interface of the i-1th film layer, so the lower interface function of the i-th film layer and the upper interface function f of the i-1-th film layer i-1 (x) are equal;

[0050] Then the thickness distribution function g of the i-th f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com