Method for preparing super-resolution imaging lens with planar zooming magnification

A technology of super-resolution imaging and magnification, applied in the directions of lenses, optics, instruments, etc., can solve the problems of low imaging quality, small effective area of imaging or lithography, difficult to meet practical applications, etc., and achieve simple and efficient processing methods. , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, making, its concrete making process is as follows:

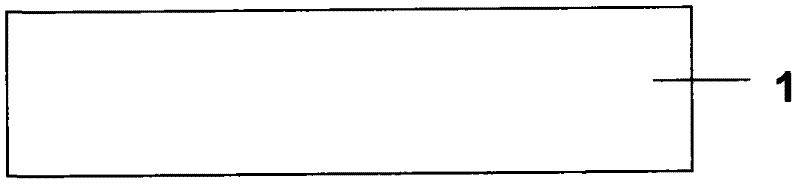

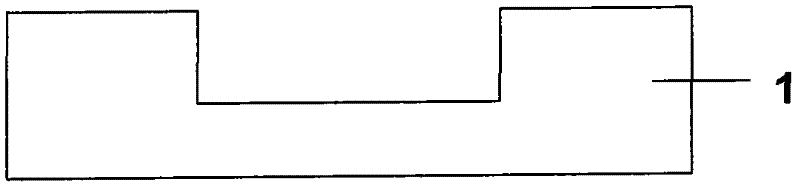

[0027] (1) in such as figure 1 Prepare a circular groove on the flat and clean quartz substrate as shown: figure 2 As shown, the bottom surface of the circular groove is a plane parallel to the substrate surface, the diameter of the upper bottom of the circular groove is 1 micron, the diameter of the lower bottom is 1 micron, and the depth is 0.5 micron.

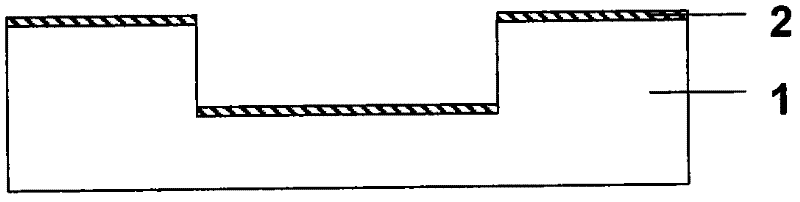

[0028] (2) if image 3 As shown, a layer of silver film is deposited on the substrate by vapor deposition, and the thickness of the silver film is 15 nanometers.

[0029] (3) if Figure 4 As shown, the method of spin coating is used to coat a layer of PMMA on the substrate, and the PMMA layer will form an arc surface in the groove under the effect of surface tension, and the PMMA is solidified after heating; the thickness of the sol layer in the groove is 15- According to the principle of minimum surface energy, the thickness distribution of the P...

Embodiment 2

[0031] Embodiment 2, making, its concrete making process is as follows:

[0032] (1) Prepare a 100*100 orthogonal array of circular grooves on a flat and clean quartz substrate; the distance between the centers of two adjacent circular grooves in each row or column is 5 microns; each circle The bottom surfaces of the circular grooves are all planes parallel to the surface of the substrate. The diameter of the upper bottom of the circular groove is 1.5 microns, the diameter of the lower bottom is 1.5 microns, and the depth is 0.6 microns.

[0033] (2) A gold film layer is deposited on the substrate by vapor deposition, and the thickness of the gold film layer is 20 nanometers.

[0034] (3) adopt the method for spin coating to coat one deck curable X-sol layer on the substrate, the X-sol layer can form arc surface in the groove under the effect of surface tension, X-sol layer solidifies after ultraviolet light irradiation; The thickness of the X sol layer in the groove is 15-50...

Embodiment 3

[0036] Embodiment 3, making, its concrete making process is as follows:

[0037] (1) Prepare a 10*10 array of square grooves arranged orthogonally on a flat and clean K9 glass substrate; the distance between the centers of two adjacent circular grooves in each row or column is 3 microns; each square The bottom surfaces of the grooves are all planes parallel to the surface of the substrate. The side length of the upper bottom of the square groove is 2 microns, the side length of the lower bottom is 1.5 microns, and the depth is 1 micron.

[0038] (2) Deposit a layer of silver film on the substrate by magnetron sputtering, the thickness of the silver film is 20 nanometers.

[0039] (3) A layer of SOG is coated on the substrate by spin coating, and the SOG layer will form an arc surface in the groove under the action of surface tension. After heating, SOG is converted into SiO 2 and solidified; SiO in the groove 2 The thickness of the layer is 15-50 nm, where according to the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com