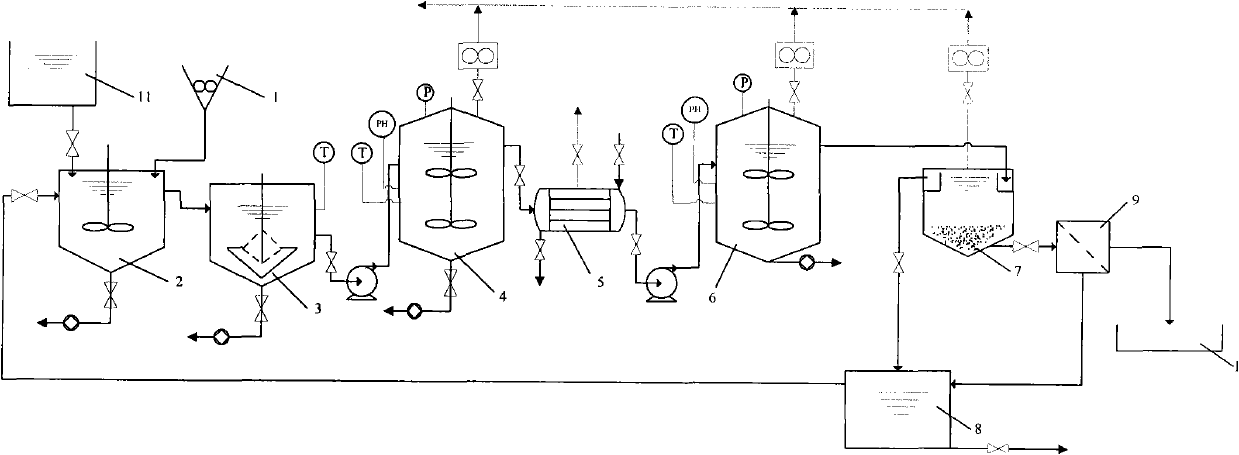

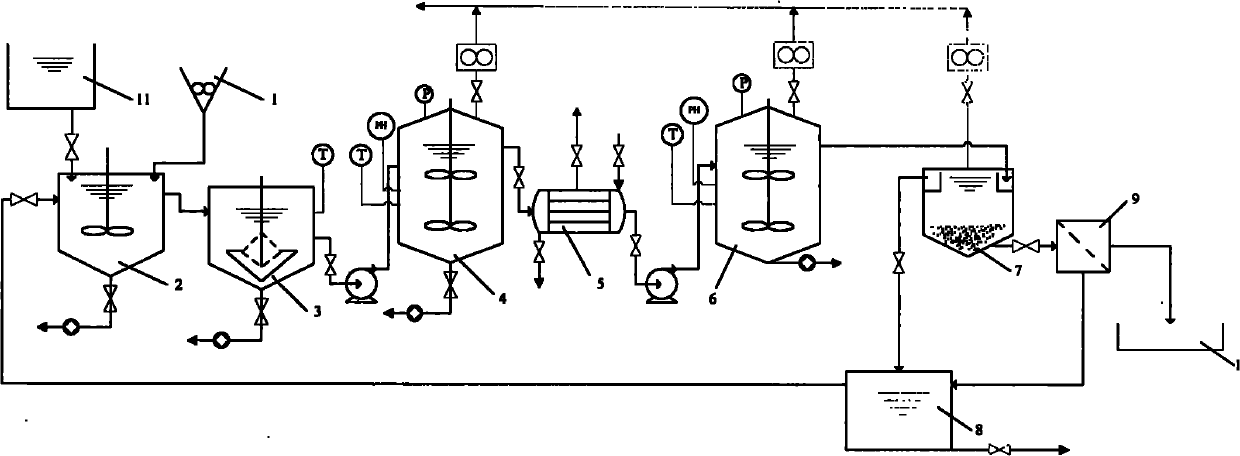

Method for generating biogas through intensified hydrolysis and anaerobic digestion of municipal domestic organic refuse

A technology of organic waste and anaerobic digestion, which is applied in the direction of waste fuel, biological sludge treatment, solid waste removal, etc., can solve the problems of restricting the use of organic waste anaerobic digestion residues as fertilizers, and cannot completely kill pathogenic bacteria, etc., to achieve Improve the removal rate of pathogenic bacteria, the removal rate of organic matter and the effect of high gas production rate of raw materials and the improvement of removal rate of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The raw material is municipal domestic organic waste collected from the source of city A, and the anaerobic digestion inoculum comes from the anaerobic activated sludge of the biogas digester.

[0027] In the mesophilic anaerobic digestion reactor, the above-mentioned anaerobic activated sludge was acclimated by using the crushed municipal domestic organic waste at a mesophilic temperature (30°C) for 10 days.

[0028] In the high-temperature anaerobic digestion reactor, the above-mentioned anaerobic activated sludge is domesticated by sampling the municipal domestic organic waste after the crushing, first domesticating the anaerobic activated sludge under the condition of medium temperature (30 ℃), and the domestication time is 10 days; then Gradually increase the temperature by 1°C per day to a high temperature (50°C), and acclimatize at a high temperature (50°C) for 5 days, and use it as an inoculum for high-temperature anaerobic digestion after the acclimatization is ...

Embodiment 2

[0040] The raw material is municipal domestic organic waste obtained through mechanical sorting from city B, and the anaerobic digestion inoculum comes from anaerobic activated sludge from municipal sewage treatment plants.

[0041] In the mesophilic anaerobic digestion reactor, the above-mentioned anaerobic activated sludge was domesticated with the crushed urban domestic organic waste at a medium temperature (35° C.) for 12 days. After the domestication was completed, it was used as the inoculum of the mesophilic anaerobic digestion.

[0042] In the high-temperature anaerobic digestion reactor, the above-mentioned anaerobic activated sludge is domesticated by sampling the municipal domestic organic waste after the crushing, first domesticating the anaerobic activated sludge under the condition of medium temperature (35 ℃), and the domestication time is 5 days; then Gradually increase the temperature by 1°C per day to a high temperature (53°C), and acclimatize at a high temper...

Embodiment 3

[0053] The raw material is municipal domestic organic waste obtained through manual sorting from city C, and the anaerobic digestion inoculum comes from the anaerobic activated sludge of the biogas digester.

[0054] In the mesophilic anaerobic digestion reactor, the above-mentioned anaerobic activated sludge was domesticated with the crushed municipal domestic organic waste at a medium temperature (38° C.) for 15 days. After the domestication was completed, it was used as the inoculum of the mesophilic anaerobic digestion.

[0055] In the high-temperature anaerobic digestion reactor, the above-mentioned anaerobic activated sludge was domesticated by the municipal domestic organic waste after the same sampling and crushing, and the anaerobic activated sludge was first domesticated under the condition of medium temperature (38 ° C), and the domestication time was 7 days; then Gradually rise to high temperature (56°C) by increasing the temperature by 1°C per day, and acclimatize ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com