Aging treatment process of Al-Zn-Mg-Cu aluminum alloy

A technology of aging treatment and aluminum alloy, which is applied in the field of aluminum alloy heat treatment, can solve the problems of limited corrosion resistance improvement, limited regression time, and inability to achieve strength and corrosion resistance, and achieve the effect of improving corrosion resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

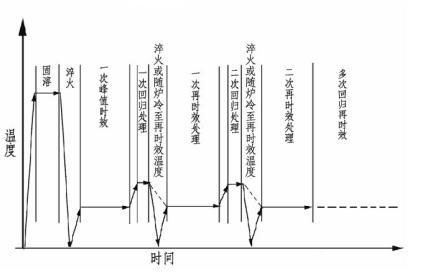

Method used

Image

Examples

Embodiment 1

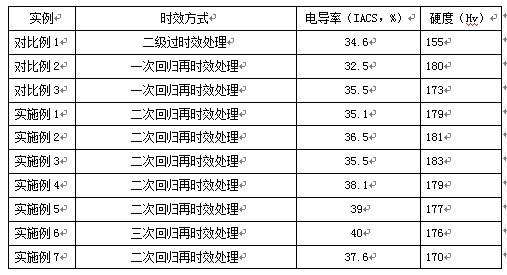

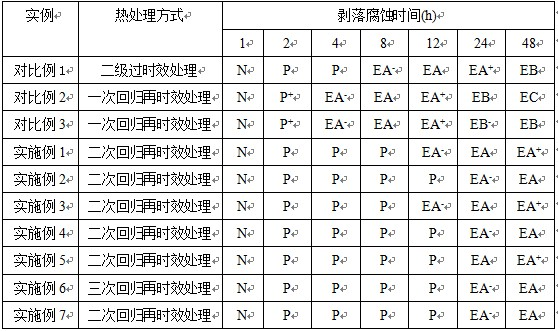

[0022] After the sample was subjected to regression and re-aging according to Comparative Example 2, the second regression and re-aging was performed at 170°C / 5min→120°C / 24h. Hardness and electrical conductivity tests were carried out after aging, and the experimental results were as follows: figure 2 shown. Exfoliation corrosion grade evaluation, the evaluation results are as follows image 3 shown.

Embodiment 2

[0024] After the sample was subjected to regression and re-aging according to Comparative Example 2, the second regression and re-aging was performed at 170°C / 30min→120°C / 24h. Hardness and electrical conductivity tests were carried out after aging, and the experimental results were as follows: figure 2 shown. Exfoliation corrosion grade evaluation, the evaluation results are as follows image 3 shown.

Embodiment 3

[0026] After the sample was subjected to regression and re-aging according to Comparative Example 2, the second regression and re-aging was performed at 200°C / 5min→120°C / 24h. Hardness and electrical conductivity tests were carried out after aging, and the experimental results were as follows: figure 2 shown. Exfoliation corrosion grade evaluation, the evaluation results are as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com