Asphalt concrete pavement utilizing self-generation of direct piezoelectric effect

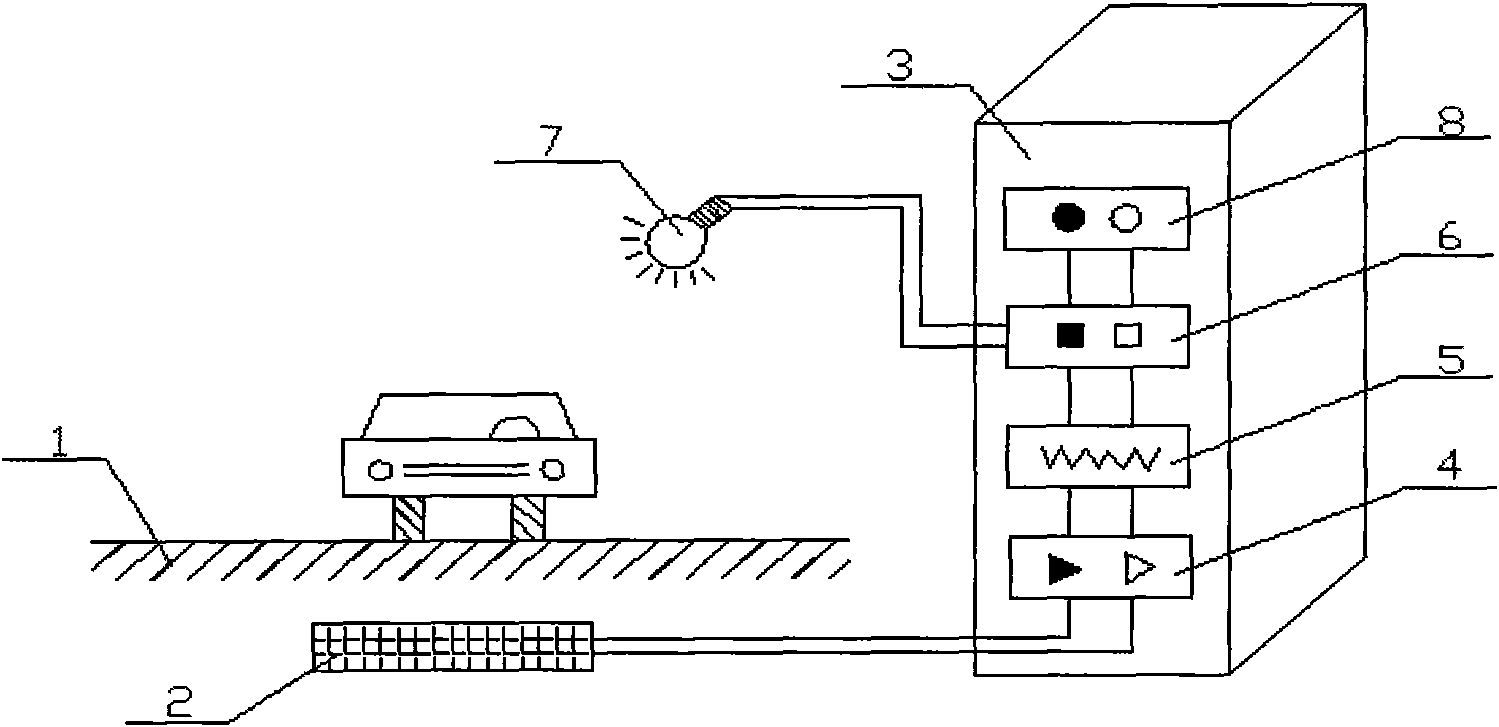

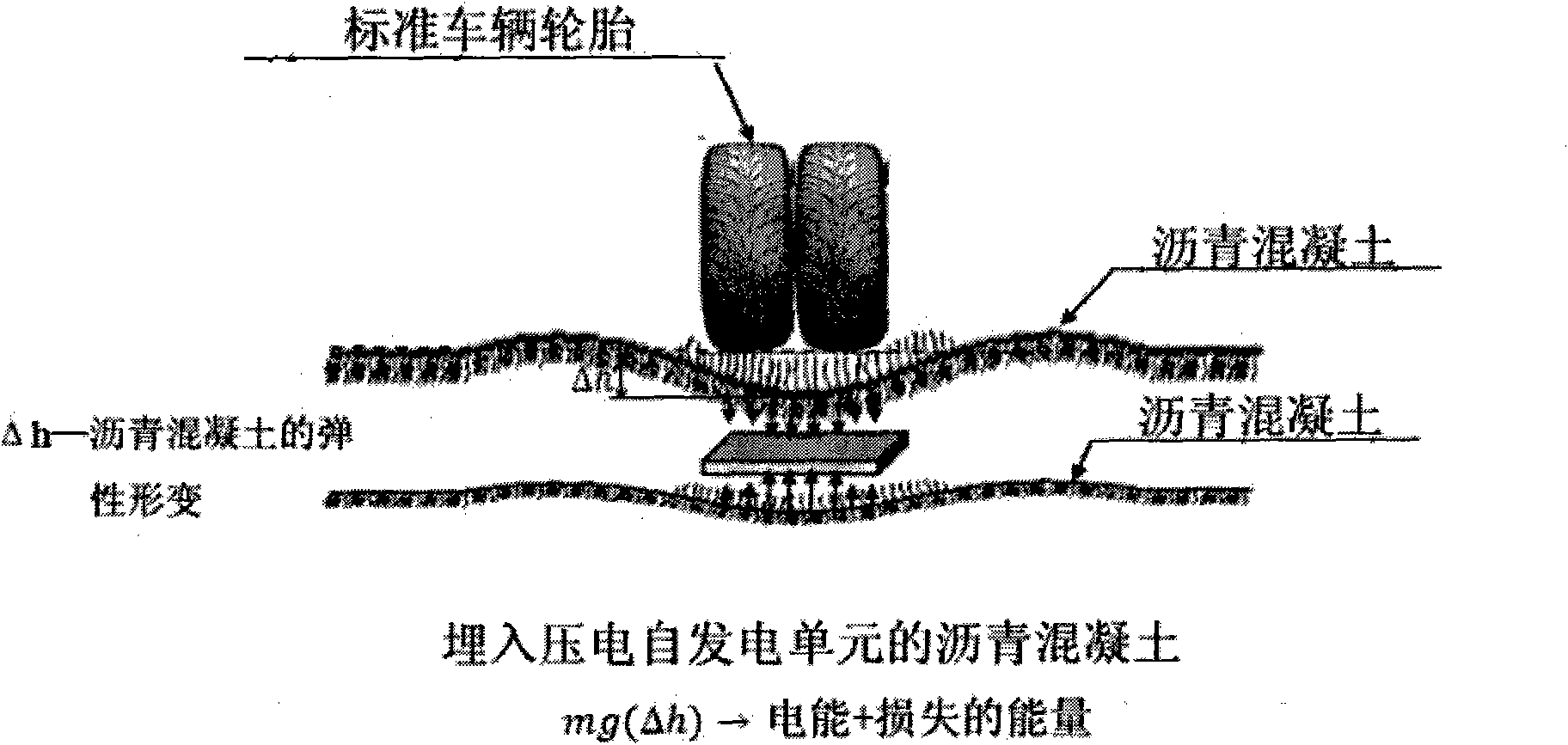

A technology of asphalt concrete and piezoelectric effect, which is applied in the field of intelligent transportation systems, can solve the problems of small road lighting, etc., and achieve the effects of reducing harmful gas, alleviating energy shortage, good road performance and anti-fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and Embodiment 2

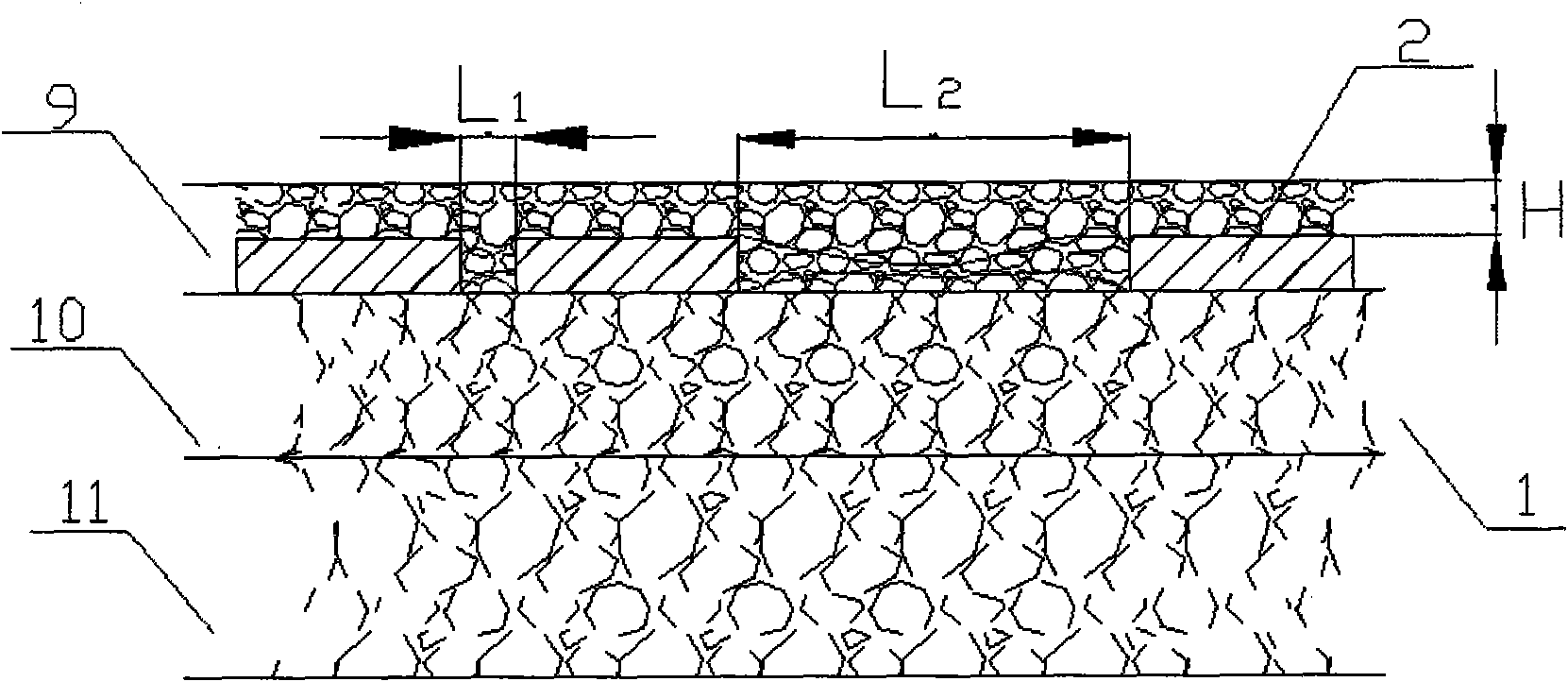

[0051] The weight ratio of ordinary asphalt concrete in embodiment 1: coarse aggregate 54%, fine aggregate 42%, slag powder 4%, asphalt 4.8%; The weight ratio of ordinary asphalt concrete in embodiment 2: coarse aggregate 54%, fine aggregate Aggregate 42%, mineral powder 4%, asphalt 4.8%, but the piezoelectric self-generating unit of length L=4cm, width W=4cm, thickness T=2cm is embedded in it. Examples 1 and 2 were formed according to the wheel rolling method of T0703-1993 in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering", and the piezoelectric self-generating unit was embedded during forming. The size of the rutting plate specimen is 300mm long x 300mm wide x 50mm high, and the piezoelectric self-generating unit is buried 20mm below the surface. Its electrical properties and road performance indicators are shown in Table 1. It can be seen from Table 1 that after the piezoelectric self-generating unit is embedded in Example 2, its road performa...

Embodiment 3、 Embodiment 4

[0052] Embodiment 3, embodiment 4 and embodiment 5:

[0053] The weight ratio of ordinary asphalt concrete in Examples 3, 4, and 5: 54% of coarse aggregate, 42% of fine aggregate, 4% of mineral powder, and 4.8% of asphalt. The rutting slab specimens were molded according to the wheel rolling method in T0703-1993 in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering", and the piezoelectric self-generating units in the above examples were embedded in the molding. The size of the rut plate specimen is 300mm long x 300mm wide x 150mm high. Example 3 was buried 20 mm below the surface, Example 4 was buried 70 mm below the surface, and Example 5 was buried 130 mm below the surface. Its electrical performance and road performance indicators are shown in Table 2. It can be seen from Table 2 that the power generation of the piezoelectric self-generating unit is related to the depth of burial. The depth increases, the power generation decreases, but the dynam...

Embodiment 6、 Embodiment 7

[0054] Embodiment 6, embodiment 7 and embodiment 8:

[0055] The weight ratio of ordinary asphalt concrete in Examples 6, 7, and 8: 54% of coarse aggregate, 42% of fine aggregate, 4% of mineral powder, and 4.8% of asphalt. The rutting slab specimens were molded according to the wheel rolling method in T0703-1993 in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering", and the piezoelectric self-generating units in the above examples were embedded in the molding. The size of the rutting plate specimen is 300mm long x 300mm wide x 50mm high, and the piezoelectric self-generating unit is buried 20mm below the surface. In embodiment 6, only 80% of the piezoelectric self-generating unit is under pressure; in embodiment 7, only 60% of the piezoelectric self-generating unit is under pressure; in embodiment 8, only 40% of the piezoelectric self-generating unit is under pressure. Its electrical performance indicators are shown in Table 3. It can be seen from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com