Vacuum prepressing method of sand-free cushion layer of secondary circulation line system

A pipeline system and secondary cycle technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of long construction period, heavy repetitive workload, high cost, etc., to reduce project cost, protect pipeline system, The effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

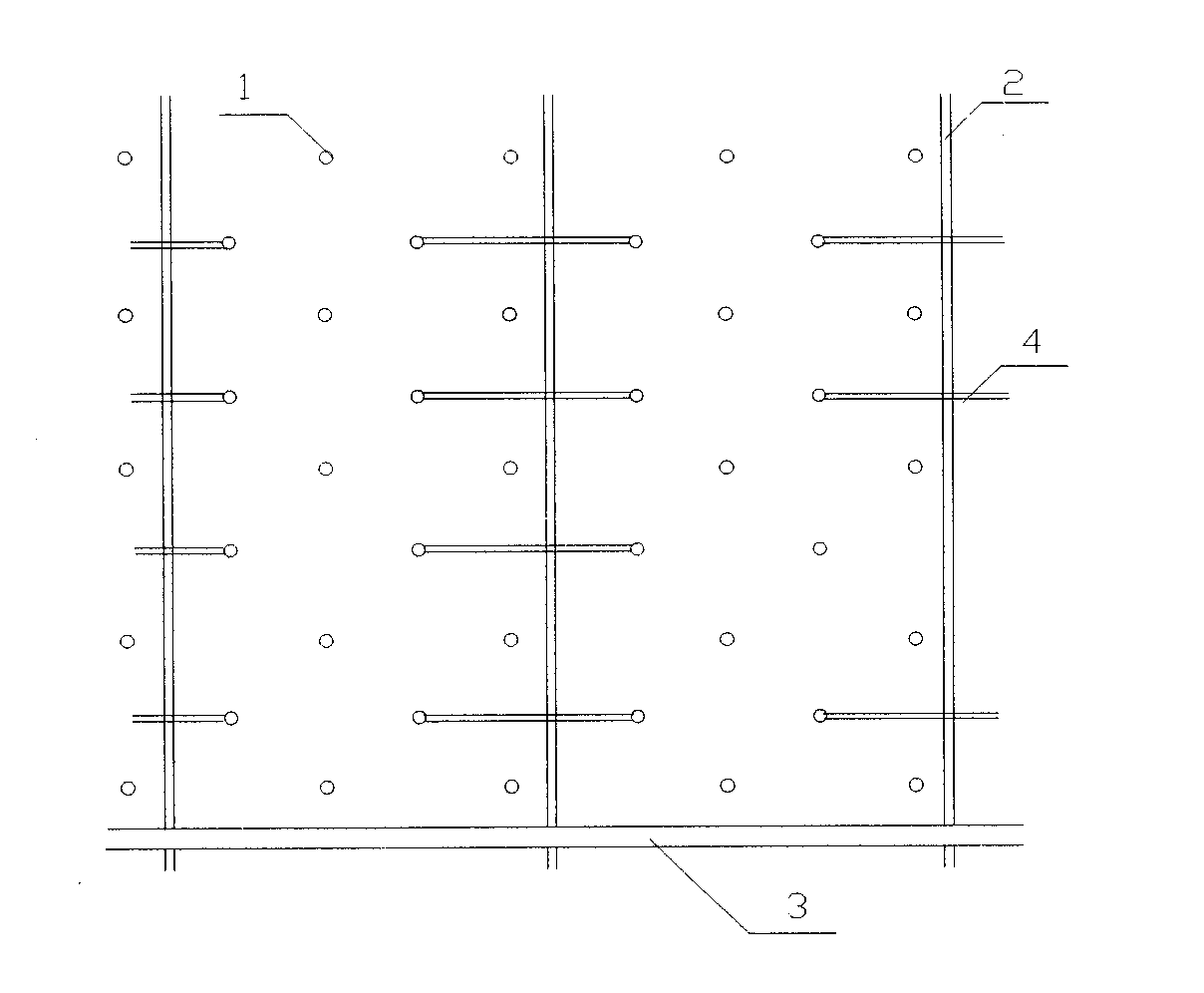

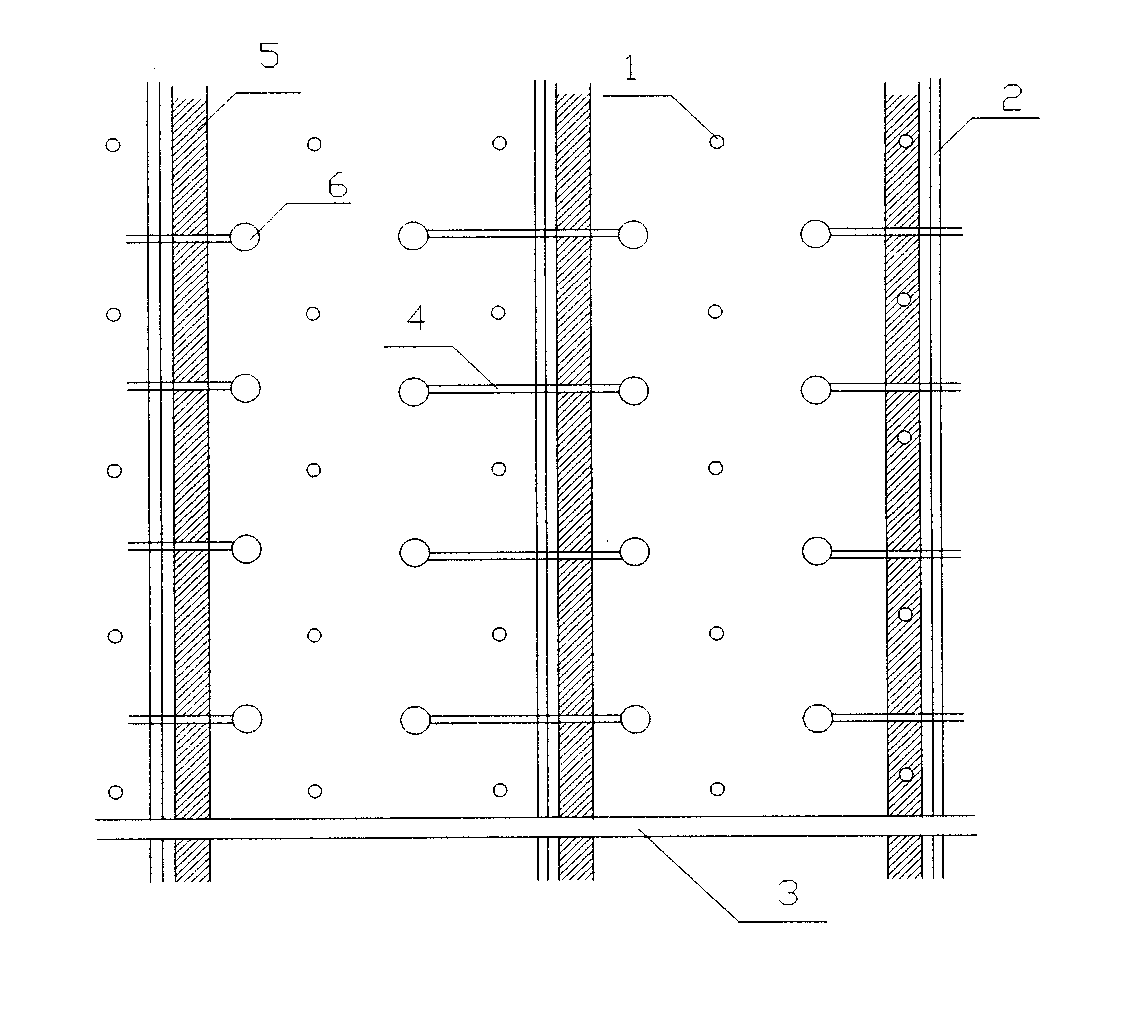

[0035] The present invention relates to a kind of non-sand cushion layer vacuum preloading treatment method that can be recycled twice for ultra-soft soil foundation pipeline, and the method includes the following process (see figure 1 with figure 2 ):

[0036] Step 1. Shallow vacuum rapid consolidation:

[0037] a) Cover the area to be treated with plastic woven cloth or geotextile, install vertical plastic drainage short boards, and lay horizontal plastic drainage short boards (about 0.5m). The length of the vertical plastic drainage short board is 1-5m, the length of the vertical plastic drainage board connected with the horizontal plastic drainage short board is 1m, the length of other vertical plastic drainage short boards is 3-5m, the vertical plastic drainage short board The board spacing is 0.6-0.9m, arranged in a plum blossom shape.

[0038] b) Laying main drainage pipes and branch drainage pipes. The main drainage pipe and the drainage pipe branch adopt water se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com