Vertical face sealing strips for guide vanes of water turbine

A technology for sealing strips and water turbines, which is applied in engine sealing, mechanical equipment, hydropower generation, etc., can solve the problems of difficult water wheel guide vanes, and achieve the effect of easy replacement and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation methods provided according to the present invention are described in detail below in conjunction with the preferred embodiments.

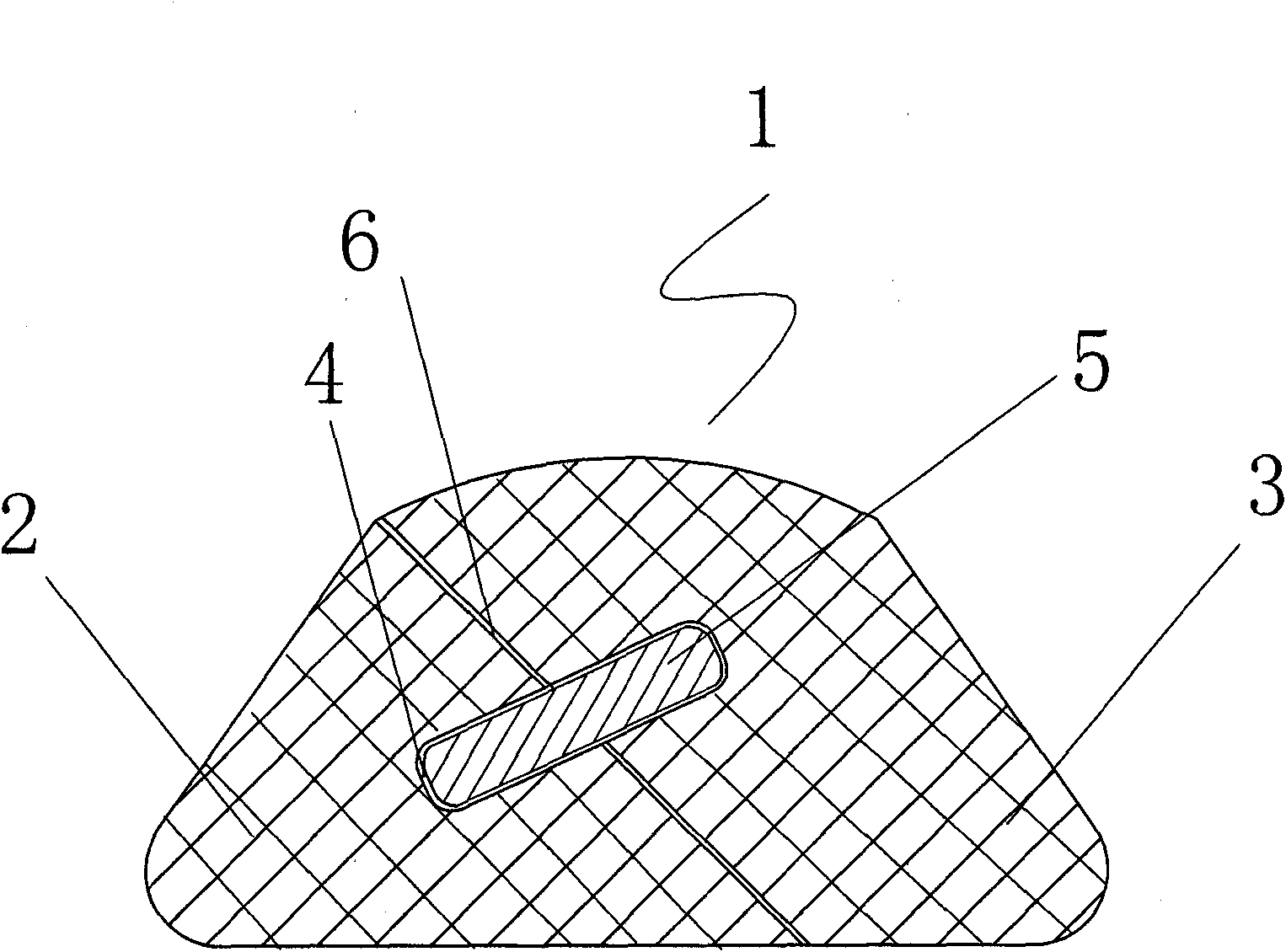

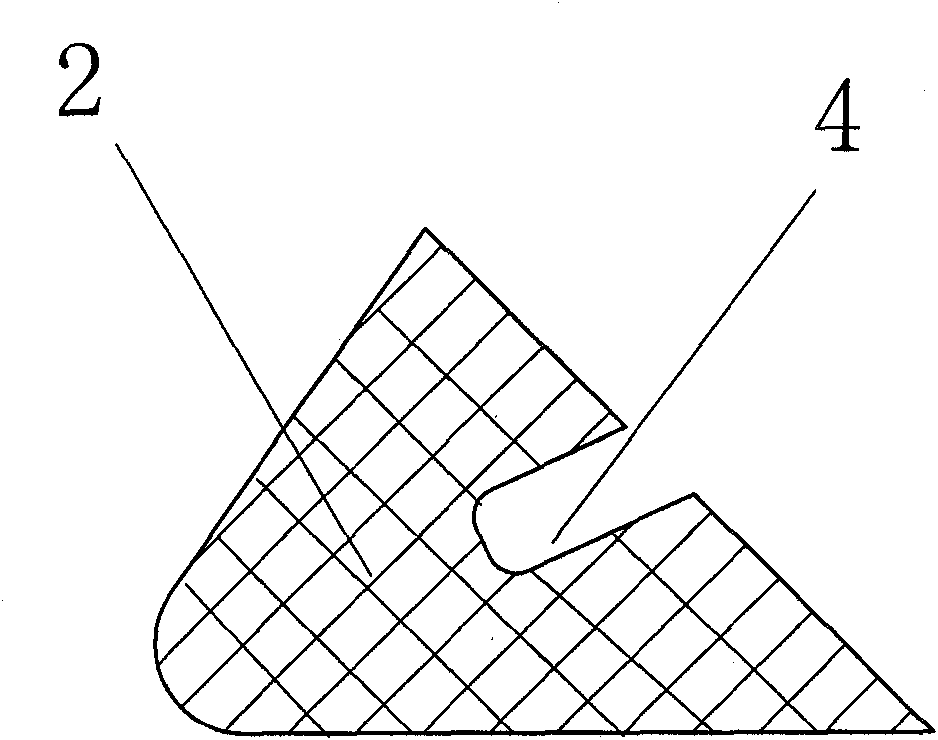

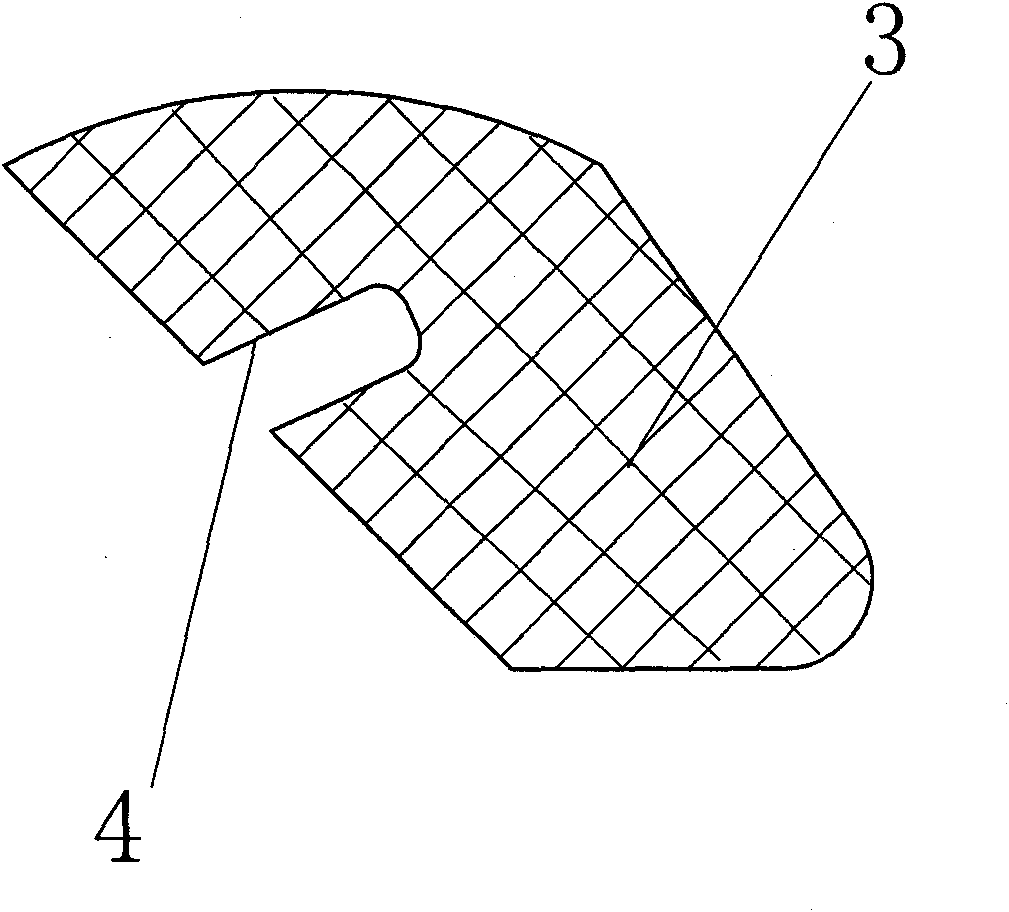

[0013] See the accompanying drawings for details, a water turbine generator guide vane façade sealing strip, including a sealing strip body 1, the sealing strip body is composed of a left sealing strip 2 and a right sealing strip 3 to form an integral sealing strip body, and the sealing The section of the bar body is an isosceles trapezoid with a circular arc on the upper part. In the middle of the integral sealing strip body composed of the left sealing strip and the right sealing strip, there is a reinforcing rib slot 4 with an angle of 25° with the bottom edge, and a reinforcing rib 5 cooperating with it is built in the groove, and the reinforcing rib Stainless steel bars are used. The integral sealing strip body is divided into several sections along the length direction, and the length of each section is 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com