Method for refining coke used for measuring coke optical texture

A technology of optical organization and coke, which is applied in the preparation of test samples, material analysis through optical means, coke oven, etc., can solve the problems of large pollution, waste of coal resources, and close coal quality, and achieve simple test equipment, Less environmental pollution and higher test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

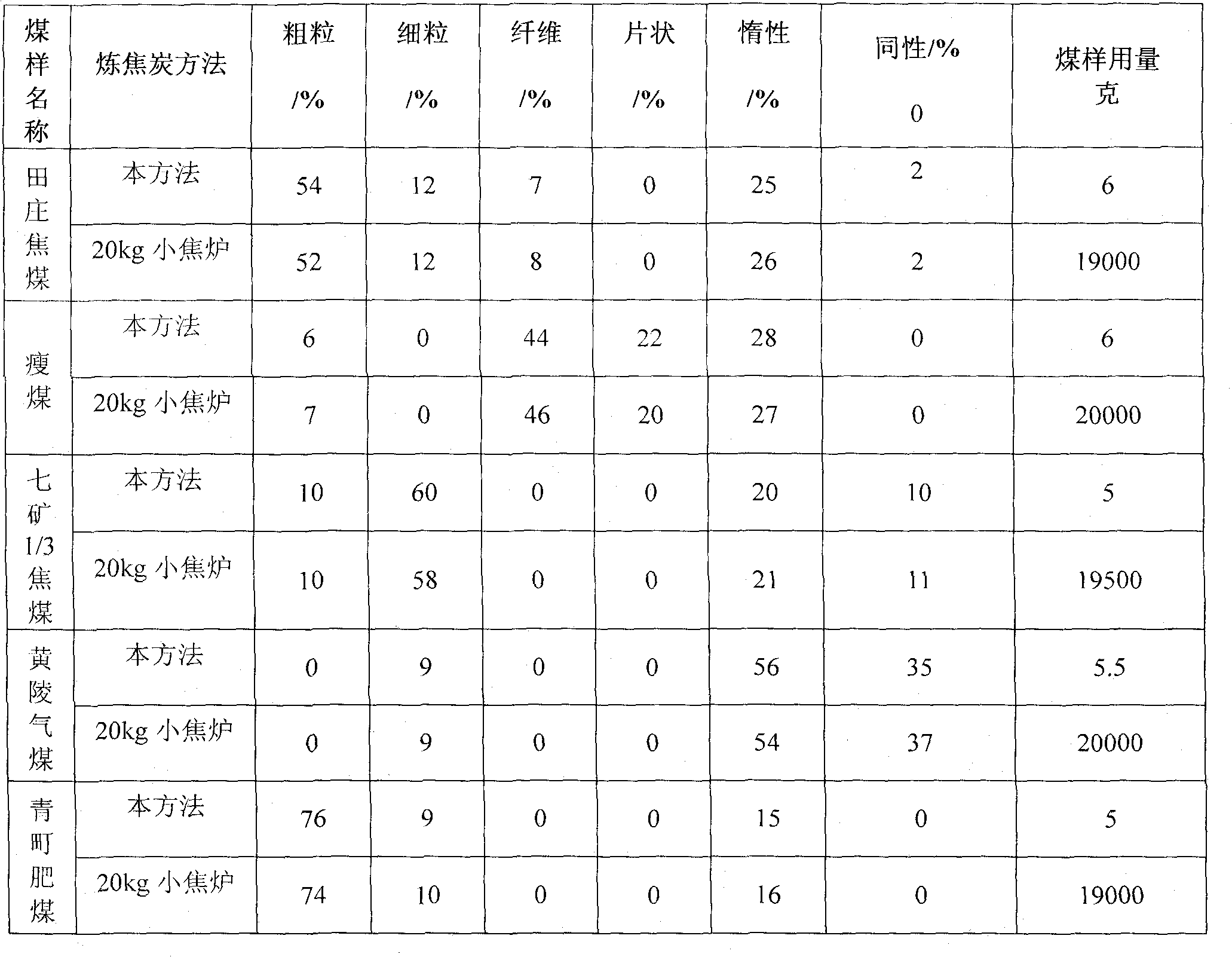

Examples

Embodiment 1

[0017] A method for refining coke for determining the optical structure of coke, the steps of which are:

[0018] 1) Five-point circular collection of Tianzhuang coking coal samples along the diagonal line of the train skin;

[0019] 2) Divide and crush the coal sample according to the "Preparation Method of Coal Sample", the particle size of which is less than or equal to 2.0 mm, and stir the crushed and sieved coal sample evenly;

[0020] 3) Put the uniformly stirred coal sample into the crucible, press a block on the surface of the coal sample, and the coverage rate of the pressed block on the surface of the coal sample is 60%; since the maximum thickness of the colloidal layer of the measured coal sample is Y The value is 18.0 mm, so there is no need to control the height of the coal sample loaded into the crucible; cover the crucible tightly; the bulk density of the coal sample after the pressurized block is 0.7g / cm 3 ;

[0021] 4) Put the crucible into a muffle furnace...

Embodiment 2

[0026] A method for refining coke for determining the optical structure of coke, the steps of which are:

[0027] 1) Collect lean coal coal samples in a five-point cycle along the diagonal line of the train skin;

[0028] 2) Divide and crush the coal sample according to the "Preparation Method of Coal Sample", the particle size of which is less than or equal to 2.0 mm, and stir the crushed and sieved coal sample evenly;

[0029] 3) Put the above-mentioned uniformly stirred coal sample into the crucible, press a block on the surface of the coal sample, and the coverage rate of the pressed block on the surface of the coal sample is 70%; since the maximum thickness of the colloidal layer of the measured coal sample is Y The value is 3.0 mm, so there is no need to control the height of the coal sample loaded into the crucible; the crucible is tightly covered; the bulk density of the coal sample after the pressurized block reaches 0.8g / cm 3 ;

[0030] 4) Put the crucible into a m...

Embodiment 3

[0035] A method for refining coke for determining the optical structure of coke, the steps of which are:

[0036] 1) Circularly collect 1 / 3 coking coal samples of No.7 Coal Mine at five points along the diagonal line of the train skin;

[0037] 2) Divide and crush the coal sample according to the "Preparation Method of Coal Sample", the particle size of which is less than or equal to 2.0 mm, and stir the crushed and sieved coal sample evenly;

[0038] 3) Put the above-mentioned uniformly stirred coal sample into the crucible, press a block on the surface of the coal sample, and the coverage rate of the pressed block on the surface of the coal sample is 82%; since the maximum thickness of the colloidal layer of the measured coal sample is Y The value is 21.0 mm, so the height of the coal sample loaded into the crucible is controlled to be 1 / 5 of the height of the crucible; the crucible is tightly covered; the bulk density of the coal sample after the pressurized block reaches 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com