Amorphous silicon film solar cell film system, and film solar cell and manufacturing method thereof

A thin-film solar cell and amorphous silicon thin-film technology, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems that restrict the application and development of thin-film solar cells, low photoelectric conversion rate, etc., and achieve the reduction of charged body Effect of recombination and retention, high photoelectric conversion rate, and increased drift speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

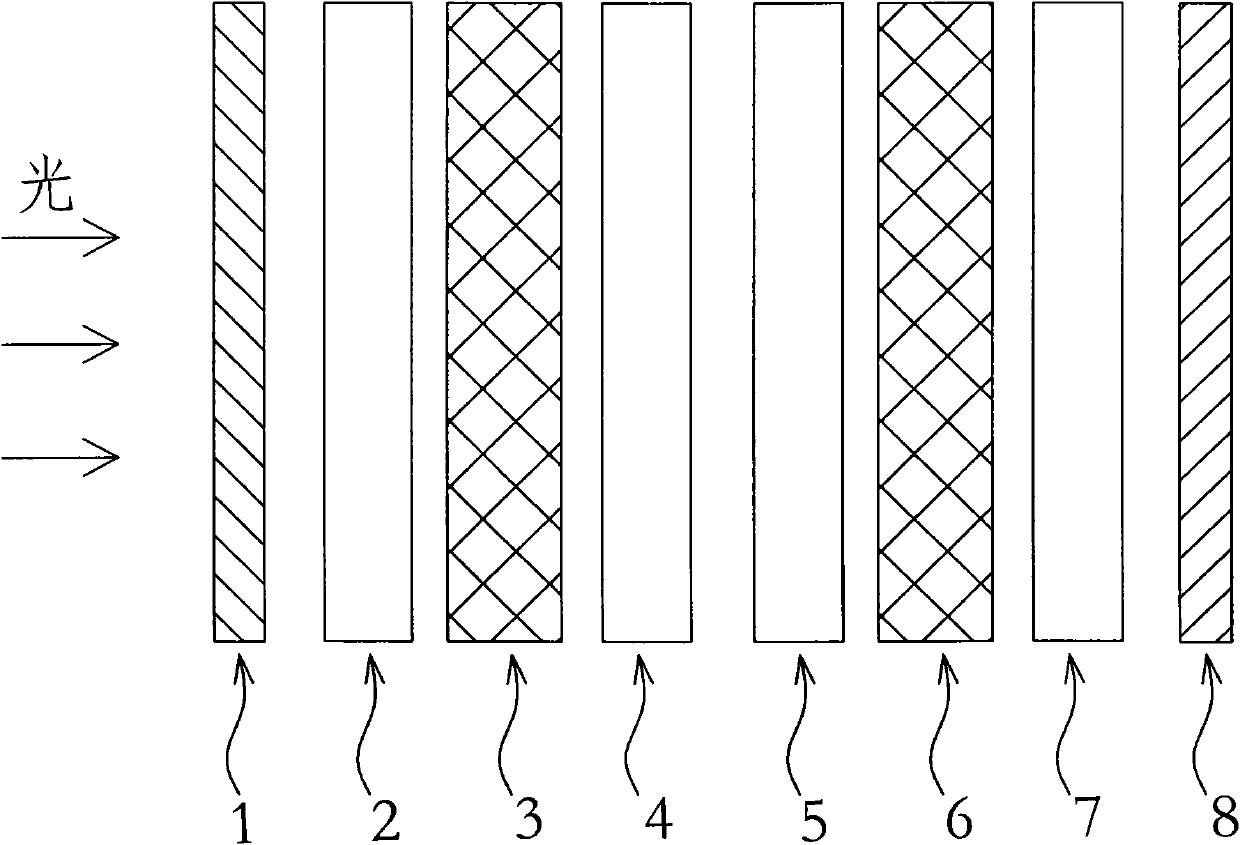

[0024] See figure 1 As shown, an amorphous silicon thin film solar cell film system is composed of the following parts:

[0025] heavily doped P + layer 1;

[0026] In heavily doped P + A first amorphous silicon p-i-n junction provided on one of the surfaces of layer 1, the first amorphous silicon p-i-n junction including p layer 2, i layer 3, and n layer 4;

[0027] A second amorphous silicon p-i-n junction arranged on the first amorphous silicon p-i-n junction, the second amorphous silicon p-i-n junction comprising a p layer 5, an i layer 6, and an n layer 7;

[0028] The heavily doped N arranged on the n layer 7 of the second amorphous silicon p-i-n junction + Layer 8.

Embodiment 2

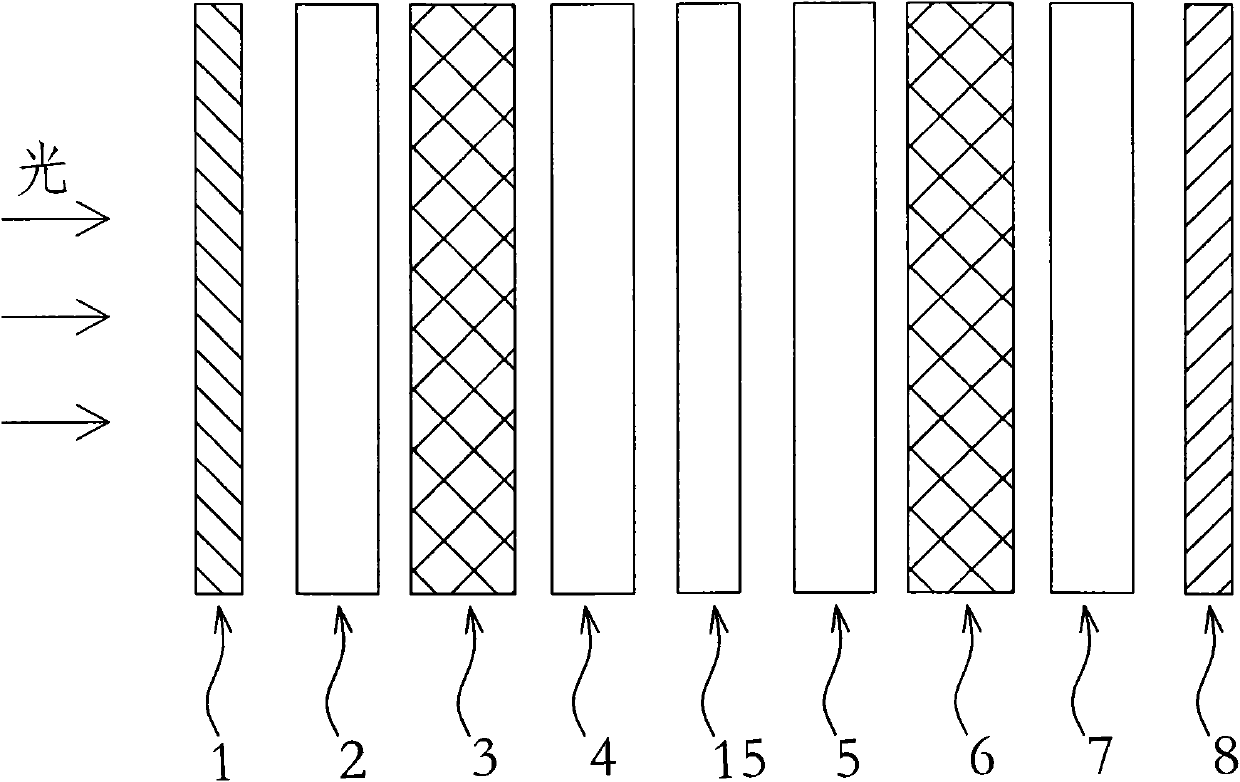

[0030] See figure 2 As shown, an amorphous silicon thin film solar cell film system is composed of the following parts:

[0031] heavily doped P + layer 1;

[0032] In heavily doped P + A first amorphous silicon p-i-n junction provided on one of the surfaces of layer 1, the first amorphous silicon p-i-n junction including p layer 2, i layer 3, and n layer 4;

[0033] A buffer layer 15 arranged on the n layer of the first amorphous silicon p-i-n junction, the buffer layer is a transparent conductive layer;

[0034] A second amorphous silicon p-i-n junction disposed on the buffer layer 15, the second amorphous silicon p-i-n junction comprising a p layer 5, an i layer 6, and an n layer 7;

[0035] The heavily doped N layer set on the n layer 7 of the second amorphous silicon p-i-n junction + Layer 8.

[0036] Adding the buffer layer 15 can increase the refraction times of light, thereby increasing the absorption ratio of light in the amorphous silicon thin film solar cell ...

Embodiment 3

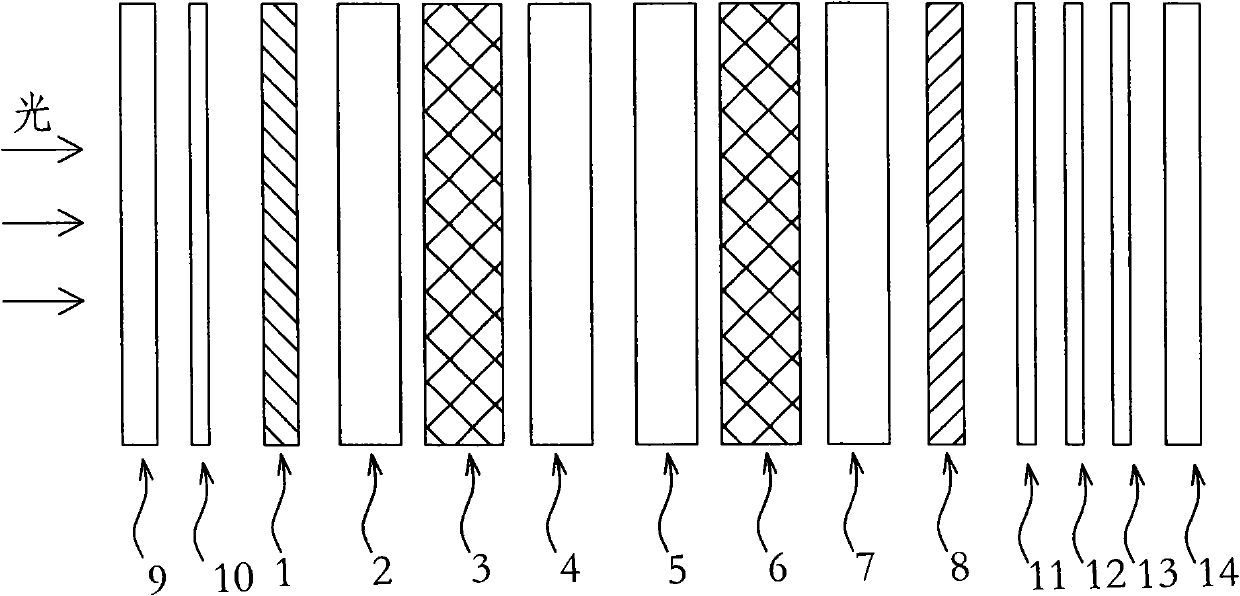

[0038] See image 3 As shown, a thin-film solar cell, the thin-film photovoltaic module of the thin-film solar cell is: along the direction of incident light, followed by a glass substrate 9, a transparent conductive film (TCO) 10 arranged on the glass substrate 9, and a transparent conductive film (TCO) 10 arranged on the transparent conductive P on membrane (TCO)10 + Layer 1, set in P + The first amorphous silicon p-i-n junction consisting of p-layer 2, i-layer 3, and n-layer 4 on layer 1, and the p-layer 5, i-layer 6, The second amorphous silicon p-i-n junction composed of n layer 7, the N disposed on the n layer 7 of the second amorphous silicon p-i-n junction + Layer 8, set in N +The ZnO layer 11 on the layer 8, the Al layer 12 arranged on the ZnO layer 11, the glued film (EVA) layer 13 arranged on the Al layer 12, the back plate glass 14 arranged on the glued film (EVA) layer 13, After heating, lamination and packaging, a thin film solar cell is produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com