Method and device for distillating vacuum film by directly utilizing vapor compression heat pump

A technology of vacuum membrane distillation and steam compressor, which is applied in the field of membrane distillation, can solve problems such as unexplained heat pumps and complex processes, and achieve the effects of reducing equipment costs, simplifying heat pump systems, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

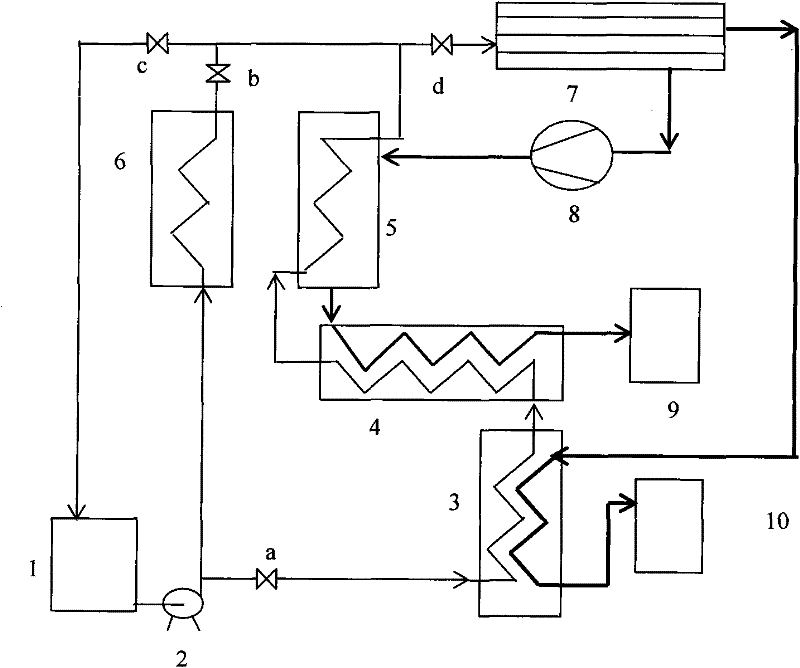

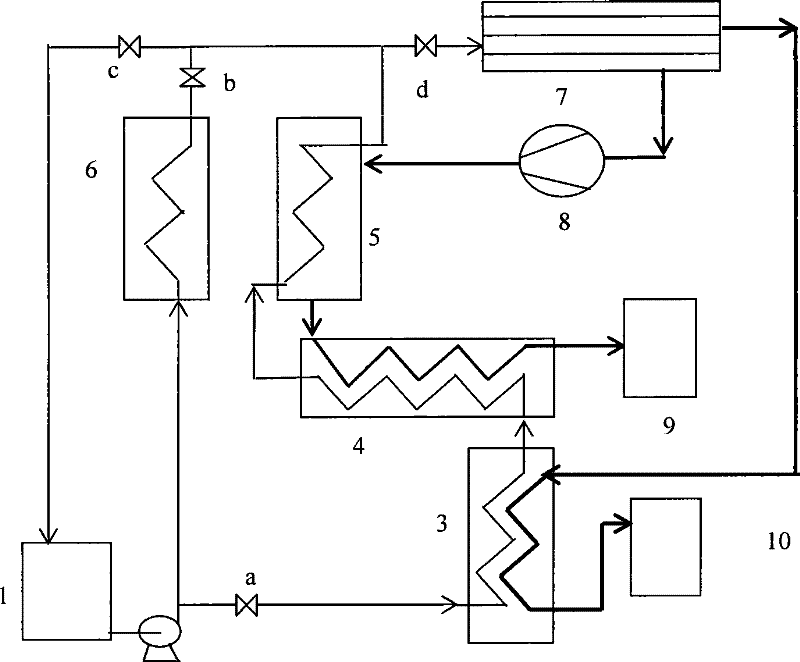

[0039] Such as figure 1As shown, a device for vacuum membrane distillation using a direct vapor compression heat pump includes a feed liquid storage tank 1, a feed liquid pump 2, an electric heater 6, a first flow regulating valve a, a second flow regulating valve b, a third Flow regulating valve c, fourth flow regulating valve d, membrane module 7, steam compressor 8, heater 5, first preheater 3, second preheater 4, condensed water storage tank 9 and concentrate liquid storage tank 10 .

[0040] Wherein, the membrane used in the membrane module 7 is a hydrophobic porous membrane, which may be a hollow fiber membrane, or a flat membrane or a tubular membrane.

[0041] The connection relationship of the above components is as follows:

[0042] The inlet of the membrane module 7 is connected with the cold side outlet of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com