Fixed gantry stand of high-depth automatic drilling machine

A gantry frame, fixed technology, applied in the field of machine tools, can solve the problems of inclination of holes, poor concentricity of holes, poor stability, etc., and achieve the effects of simple mechanism, reliable installation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

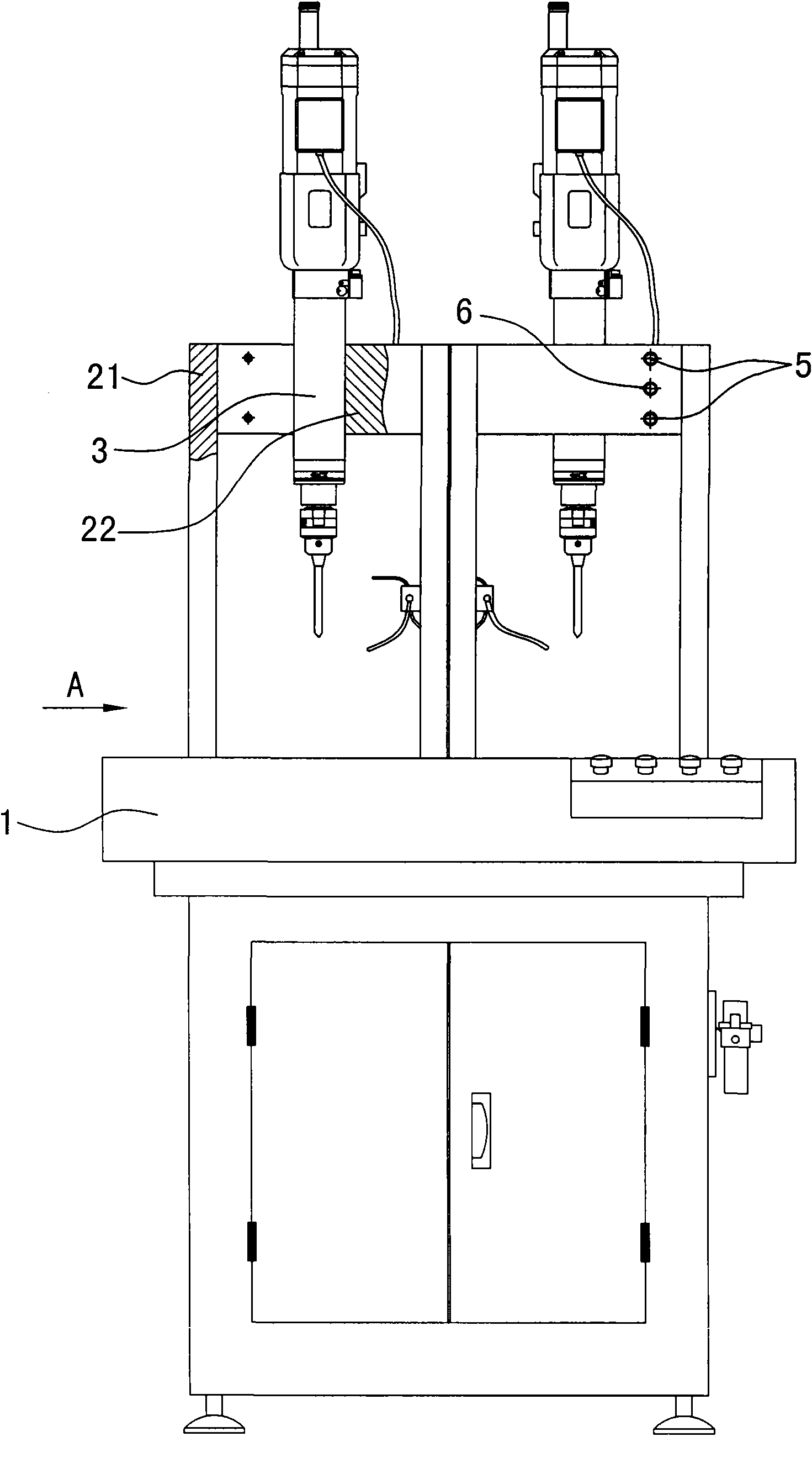

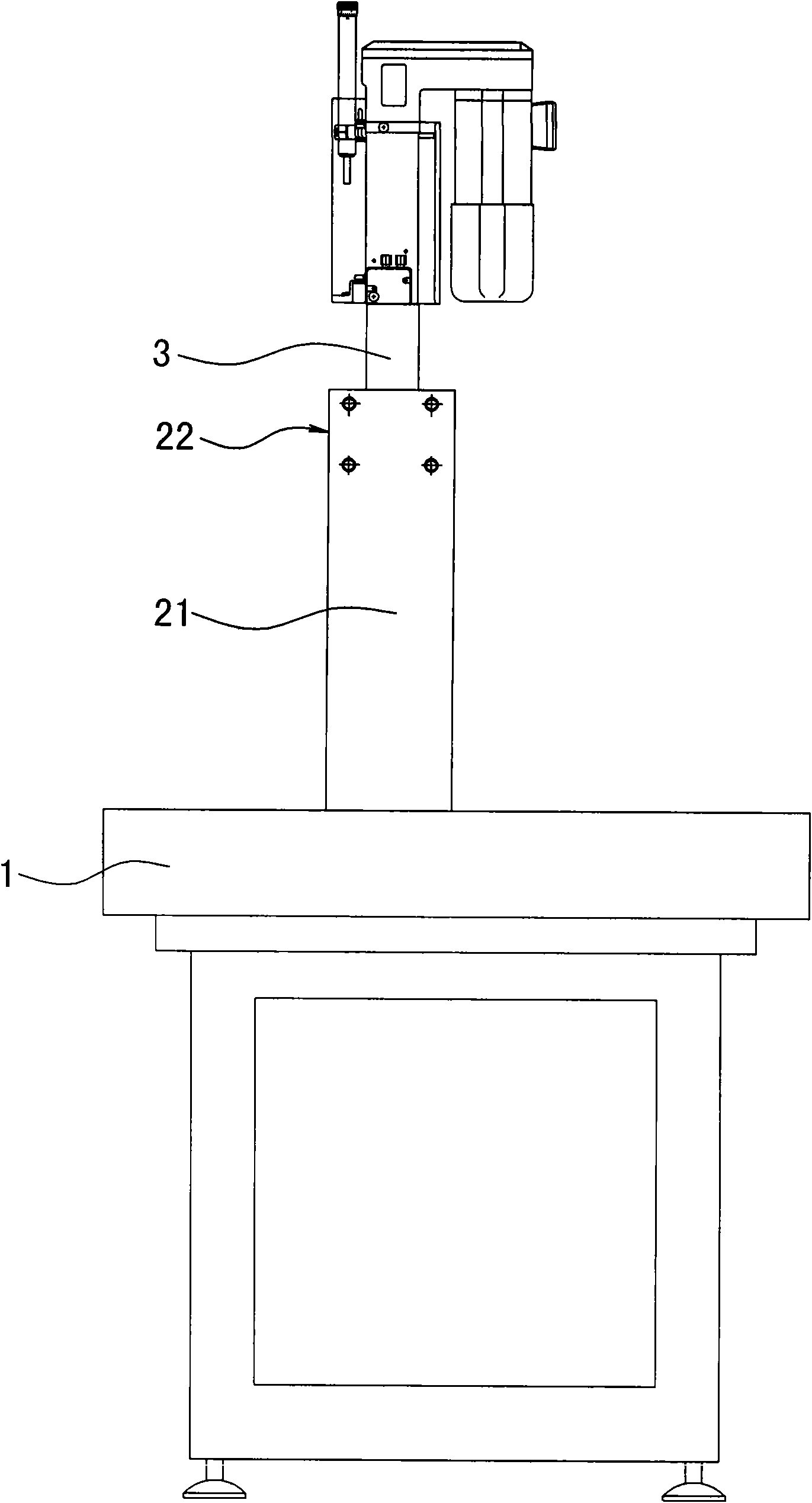

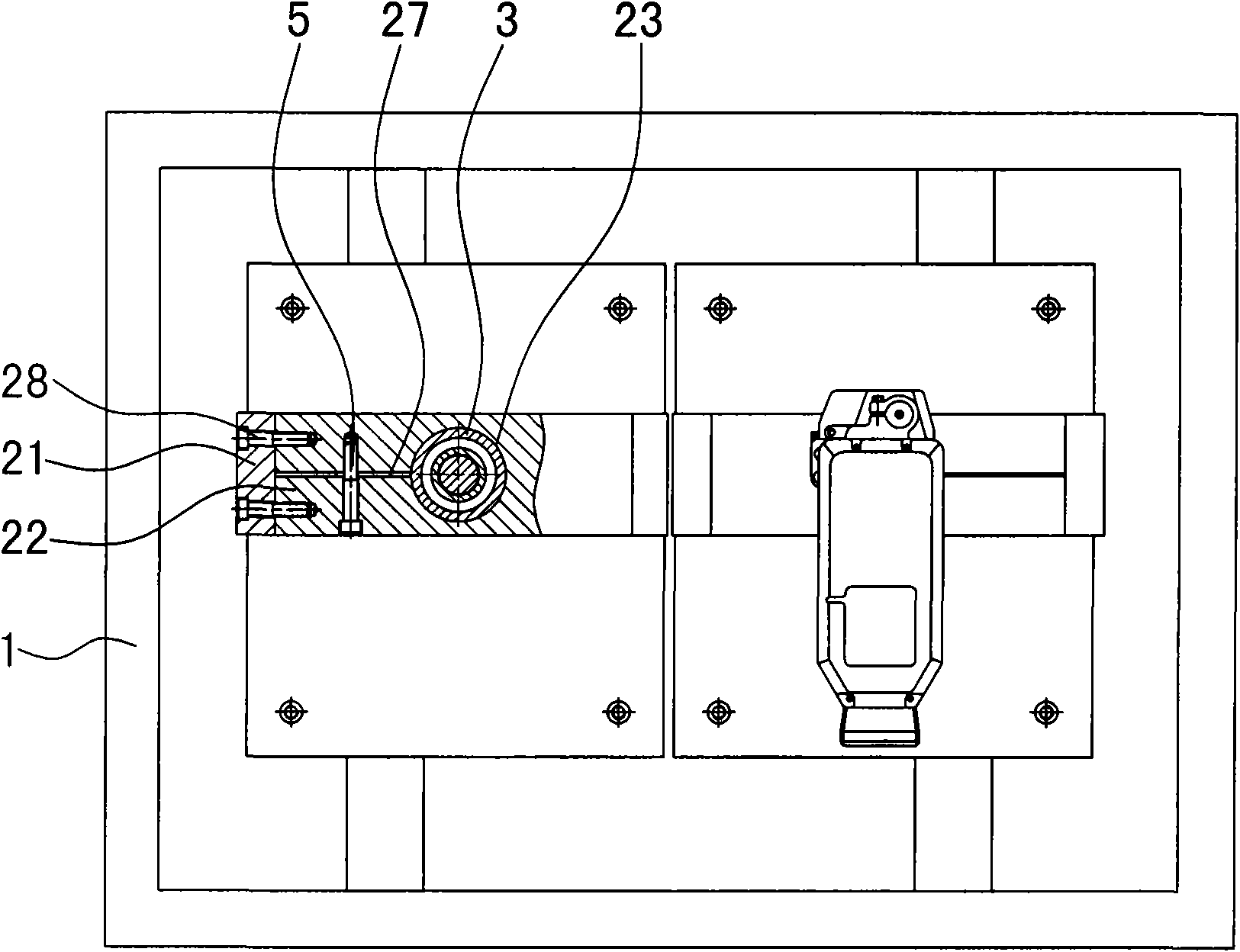

[0011] The invention discloses a fixed gantry frame of a high-depth automatic drilling rig, such as figure 1 , figure 2 As shown, it includes a machine base 1, which is connected to the frame, and the frame has a fastening mechanism, which is fixed to the power head. It is characterized in that the frame includes vertical plates 21 and horizontal plates 22 perpendicular to each other. Fixed connection, the vertical plate is fixed on the machine base 1, the fastening mechanism includes a fastening hole 23 formed in the horizontal plate 22, the power head 3 is installed in the fastening hole 23, and the fastening hole 23 has a locking mechanism , the frame is mainly composed of vertical plates 21 including columns, poles, etc., and horizontal plates 22 (beams). , and directly be shaped on fastening hole 23 in horizontal plate 22, take fastening hole 23 as fastening mechanism, power head 3 is installed in fastening hole 23, make the center of power head 3, center of gravity inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com