Automatic tip repairing machine of fixed welding gun electrodes on welding line

A grinding device and fixed welding technology, used in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of large movement space of the turning mechanism, prone to failure, unfavorable maintenance, etc., to save space, avoid interference, The effect of easy operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

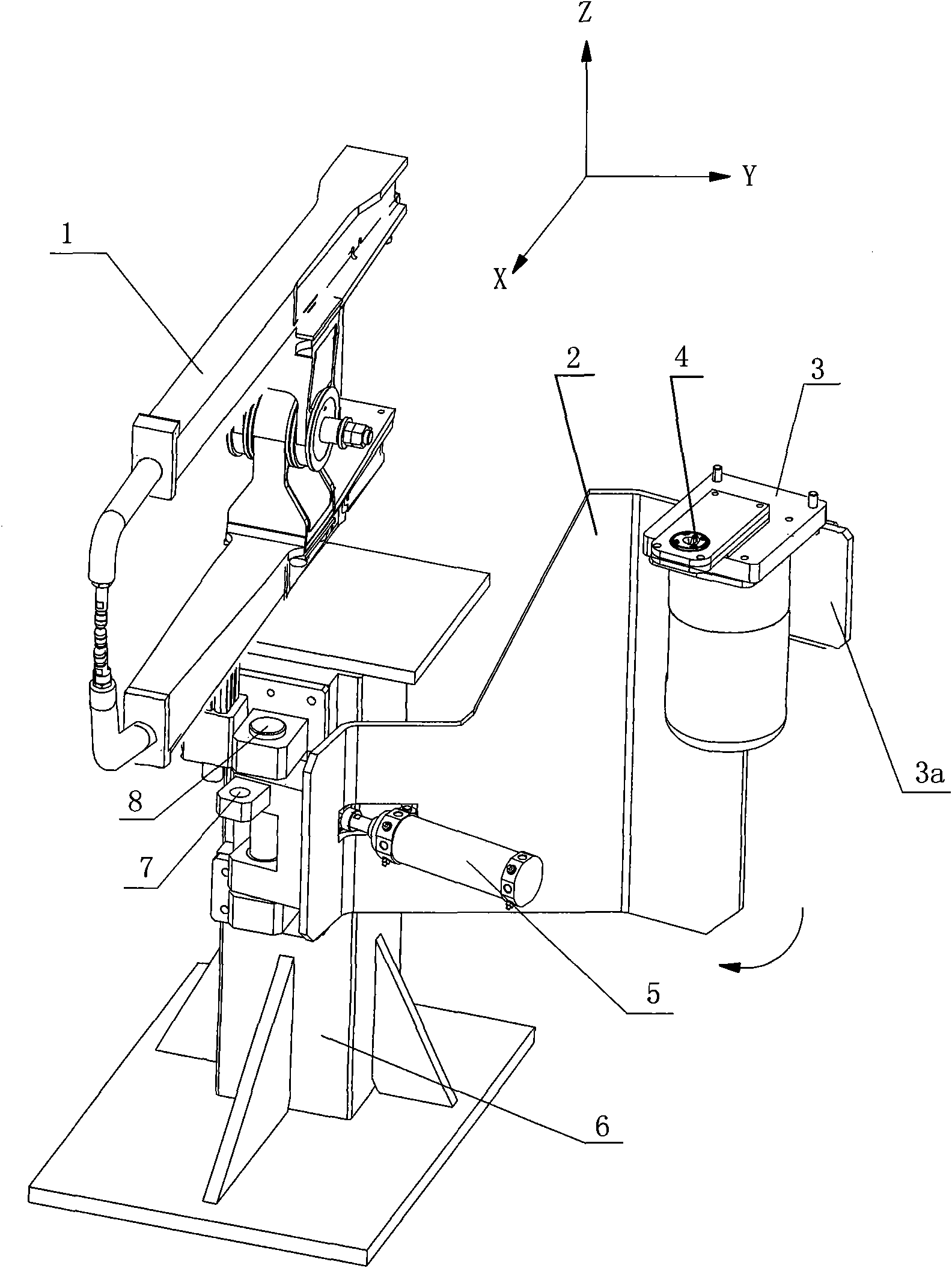

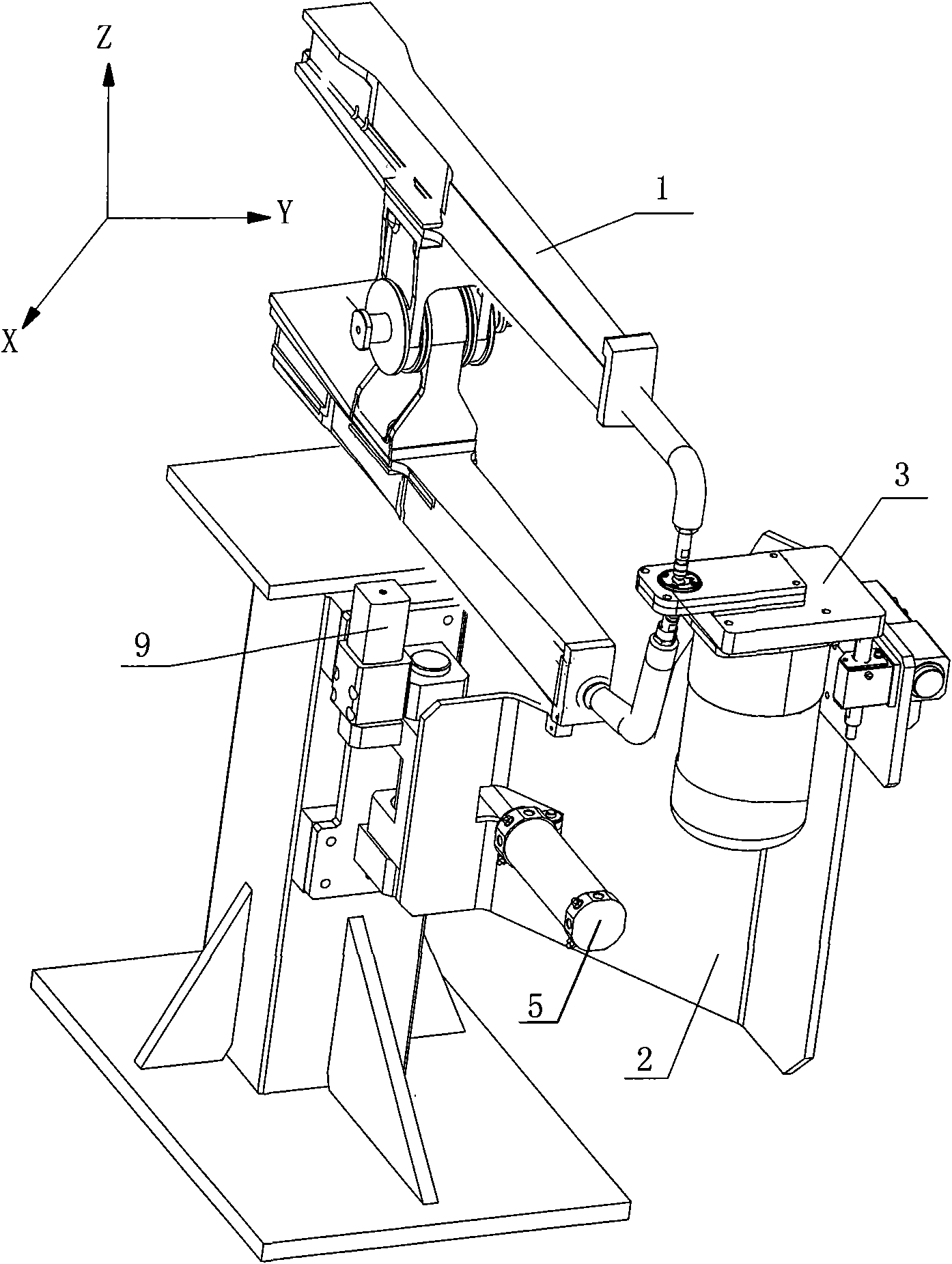

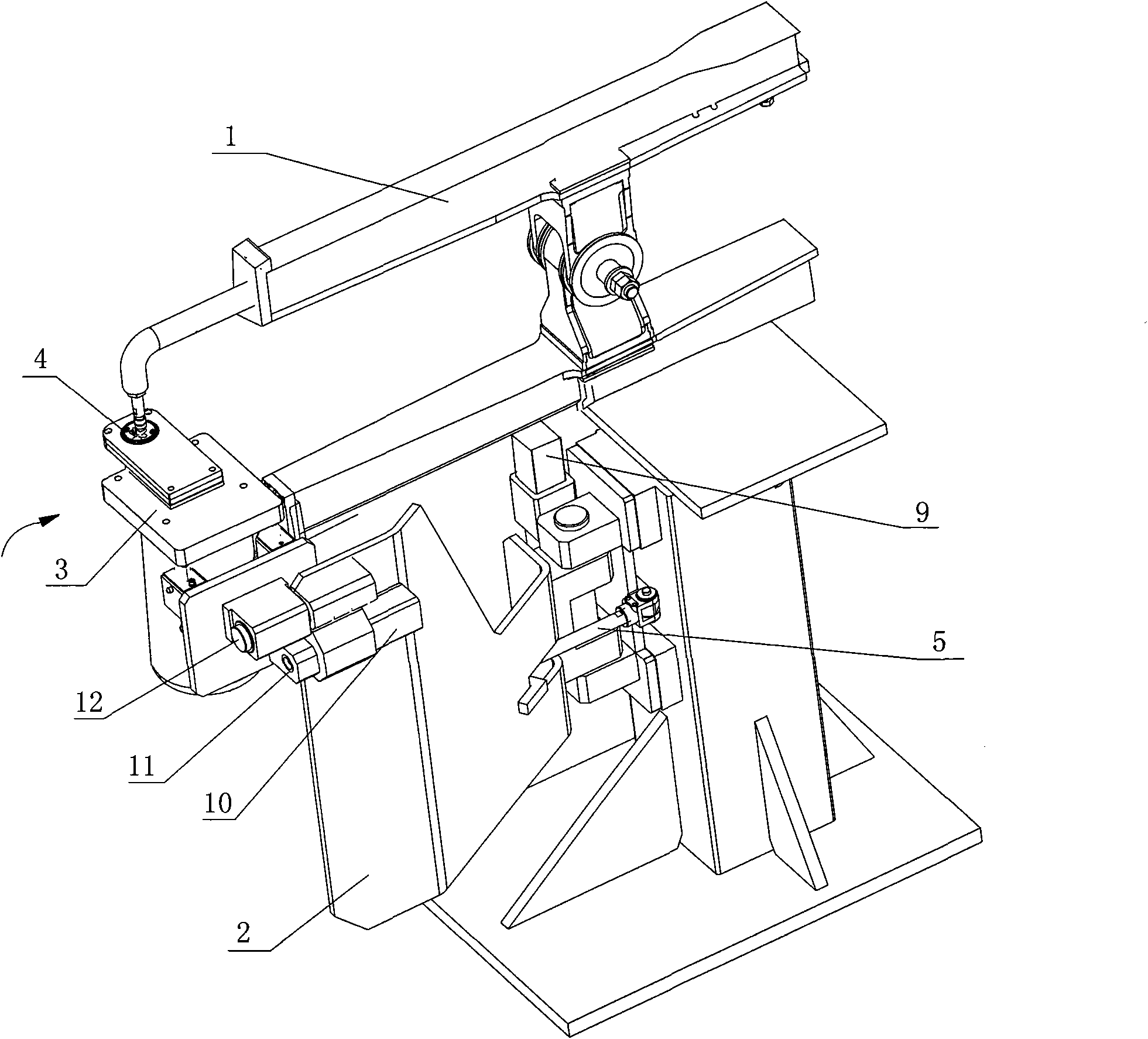

[0026] see figure 1 and figure 2 , on the bracket 6 of the welding gun 1, a rotating shaft 8 is arranged in the Z direction, and a rotating arm 2 with the rotating shaft 8 as the rotation center and which can rotate in the XOY plane is arranged on the rotating shaft 8. Between the bracket 6 and the rotating arm 2, a The swing cylinder 5 that forms a triangular support to the swing arm, the dresser 3 is fixedly installed on the outside of the swing arm 2 through the dresser backboard 3a, and the rotary blade 4 driven by a motor is set on the dresser 3; The rotating arm 2 under driving has two state positions, and one is that the rotating blade 4 on the dresser 3 is in the working position between the cathode and the anode of the welding torch 1 (such as figure 2 shown); the other is an idle position to prevent the dresser 3 from interfering with the welding torch 1 (such as figure 1 shown).

[0027] In specific implementation, the corresponding structural settings also inc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap