Propulsion unit of contra-rotating propellers of electric ship

A technology for electric ships and propulsion devices, which is applied in ship propulsion, mechanical gear transmission devices, propulsion components, etc., can solve the problems of large bearing load, large vibration, and large gear transmission power loss, and achieves low bearing load, simple structure, Smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

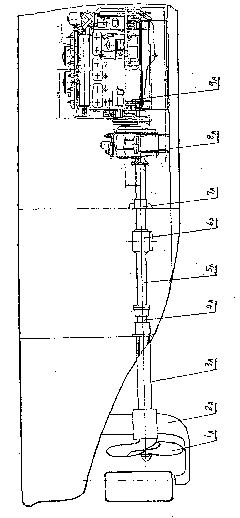

[0022] For convenience and clarity, like symbols refer to like components and structures throughout the drawings. see figure 1 , the traditional cockpit propulsion device includes: an engine 9A fixed in the nacelle, a transmission gearbox 8A connected to the flywheel of the engine at one end, and an intermediate transmission shaft 5A connected to the outlet flange of the transmission gearbox with bolts at one end (including a compartment stuffing box 7A and intermediate bearing 6A) a stern tube 3A and a stern shaft 4A connected to the rear end of the intermediate drive shaft, and a propeller 1A installed on the stern shaft 4A extending out of the gable frame 2A.

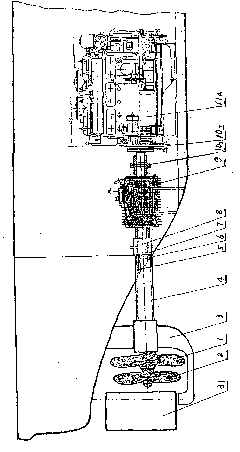

[0023] see figure 2 , see "ship contra-rotating propeller propulsion device" (invention patent application number: 200710047212.5) and will not be introduced here

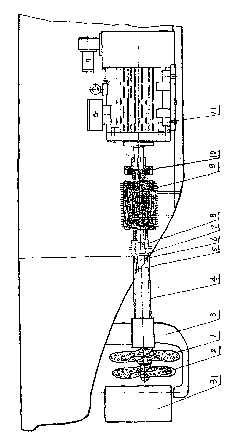

[0024] see image 3 The contra-rotating propulsion device for electric ships of the present invention comprises: a DC (or AC) motor 11 fixed in the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com