Low temperature resistant high-transparency CPP packaging film capable of printing internally

A high-transparency, packaging film technology, used in packaging, wrapping paper, transportation and packaging, etc., can solve problems such as unsatisfactory production conditions, low economic benefits, and unbalanced production and sales, to promote technological progress and increase market share. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

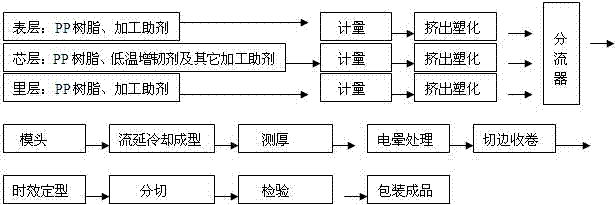

Method used

Image

Examples

Embodiment Construction

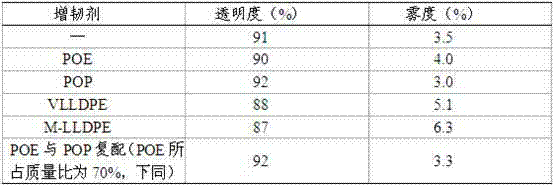

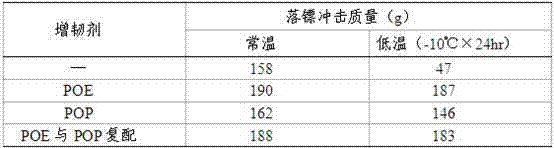

[0022] 1 Screening of tougheners

[0023] Layer A is PP resin, layer C is terpolymerized PP resin and 1.2 parts (parts by mass, the same below) of slip agent, layer B is PP resin without adding and adding 7 parts (parts by mass, the same below) Toughening agent, the mass ratio of the three layers: A layer 18%, B layer 64%, C layer 18% (the same below). The measured transparency and haze of the 38 μm film are shown in Table 1.

[0024] Table 1 Effect of toughening agent on film transparency and haze

[0025]

[0026] Table 1 shows that ULLDPE and M-LLDPE will reduce the transparency of the film and increase its haze, while POE, POP and their compound tougheners can improve the transparency of the film and reduce its haze. This should be due to the different compatibility between different tougheners and copolymer materials. ULLDPE, M-LLDPE and HPP have poor compatibility, so the transparency is poor and the haze is high. The compatibility of POE and POP and their compound ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com