Environment-friendly degradable BOPP synthetic label film coating and preparation method thereof

A paint and label technology, applied in the field of environmentally friendly and degradable BOPP synthetic label film paint and its preparation, can solve the problems of low surface energy of BOPP synthetic paper, poor printing effect of BOPP synthetic paper, etc., and achieve good printing and dyeing effect, good printing effect, Uniform effect of label film coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

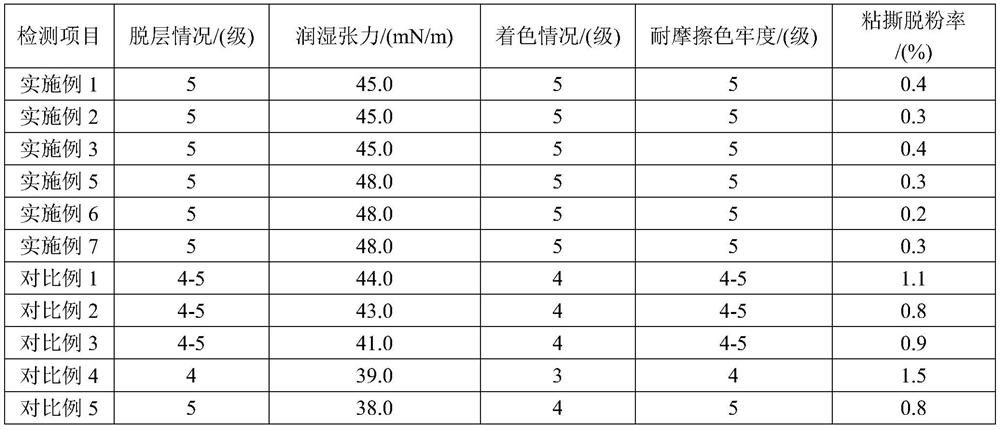

Examples

preparation example 1

[0041] Antistatic agent is prepared by the following method:

[0042] Under the condition that the temperature is 50° C., ethoxylated coconut oil alkylamine, carboxymethyl amphoteric imidazoline, and sodium secondary alkylsulfonate are uniformly mixed to obtain an antistatic agent.

[0043] Wherein, the weight proportion of ethoxylated coconut oil alkylamine, carboxymethylamphomoimidazoline and sodium secondary alkylsulfonate is 3:1:0.1.

preparation example 2

[0045] Antistatic agent is prepared by the following method:

[0046] Under the condition that the temperature is 50° C., ethoxylated coconut oil alkylamine, carboxymethyl amphoteric imidazoline, and sodium secondary alkylsulfonate are uniformly mixed to obtain an antistatic agent.

[0047] Wherein, the weight ratio of ethoxylated cocoalkylamine, carboxymethylamphomoimidazoline and sodium secondary alkylsulfonate is 4:1:0.2.

preparation example 3

[0049] Antistatic agent is prepared by the following method:

[0050] Under the condition that the temperature is 50° C., ethoxylated coconut oil alkylamine, carboxymethyl amphoteric imidazoline, and sodium secondary alkylsulfonate are uniformly mixed to obtain an antistatic agent.

[0051] Wherein, the weight proportion of ethoxylated cocoalkylamine, carboxymethylamphomoimidazoline and sodium secondary alkylsulfonate is 5:1:0.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com