A production process of high-clean surface medical aluminum foil

A production process, aluminum foil technology, applied in the production process field of high-clean surface pharmaceutical aluminum foil, can solve the problem of not being able to meet the quality requirements of high-quality pharmaceutical aluminum foil, affecting the surface quality and hygienic quality of pharmaceutical aluminum foil, and the wetting tension of the positive surface of aluminum foil Low value and other problems, to achieve the effect of low viscosity, high wetting tension, and avoid aluminum powder falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A production process of a high-clean surface pharmaceutical aluminum foil, comprising the following steps:

[0021] Step 1. The casting and rolling material with the specification of 0.26×1150mm and the alloy of 8011H16 is used as the billet. Use a rough roll with a roughness Ra: 0.23um from 0.26mm-0.145mm-0.075mm, after 2 passes of rolling, then use a roll with a Ra: 0.12um to roll for 1 pass; get an aluminum sheet with a thickness of about 0.040mm .

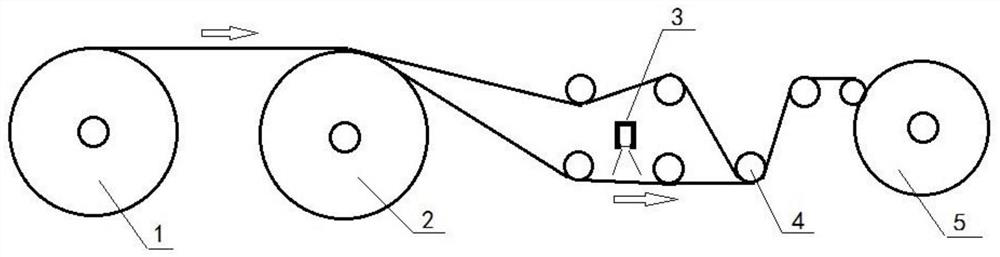

[0022] Step 2, carry out the above-mentioned aluminum thin plate with a thickness of 0.04mm figure 1 After the coils are oiled in the middle as shown, they are transferred to the finishing mill for double rolling.

[0023] Step 3. Before double-rolling in the finishing mill, empty out the previously prepared rolling oil containing additives, add pure base oil again, and after a 60-min cycle, use a roll with a roughness of Ra: 0.10 to perform 0.04mm-0.02mm The thickness is double-rolled to obtain the thickness required...

Embodiment 2

[0027] A production process of a high-clean surface pharmaceutical aluminum foil, comprising the following steps:

[0028] Step 1. The casting and rolling material with the specification of 0.26×1150mm and the alloy of 8011H16 is used as the billet. Use a rough roll with a roughness Ra: 0.23um from 0.26mm-0.145mm-0.075mm, after 2 passes of rolling, then use a roll with a Ra: 0.12um to roll for 1 pass; get an aluminum sheet with a thickness of about 0.040mm .

[0029] Step 2. Attach an aluminum sheet with a thickness of 0.04mm figure 1 After the coils are oiled in the middle as shown, they are transferred to the finishing mill for double rolling.

[0030] Step 3: Carry out double rolling with ordinary rolling oil for aluminum foil production. During the rolling process, turn off the motor drive of the exit guide rollers, and restore the guide rollers to the state of the original idler rollers for production. The surface wetting tension of the first material inspection alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com