Air source heat pump for radiating heat by spraying and defrosting by using hot water

An air source heat pump and hot water technology, applied in lighting and heating equipment, machine operation, heating and cooling combination, etc., can solve the problems of decreased efficiency, difficulty in improving heat dissipation effect, easy frosting and heat exchange efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

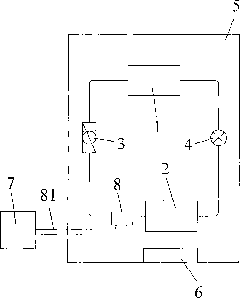

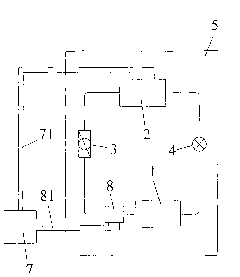

[0012] Example: see Figure 1-3 , the first heat exchanger 1 and the second heat exchanger 2 in the casing 5 of the present invention form a closed-loop system via the compressor 3 and the expansion valve 4, and the first heat exchanger 1 and the second heat exchanger 2 have heat exchange pipeline.

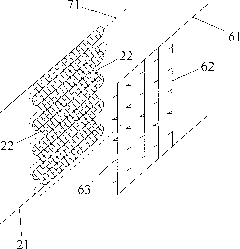

[0013] When working in cooling mode in summer, the second heat exchanger 2 acts as a condenser, and a spray device 6 is arranged beside the second heat exchanger 2, and the spray device 6 sprays water mist on the heat exchange pipe 21 of the second heat exchanger. And on the fins 22 between the heat exchange pipes of the second heat exchanger, the principle of water vapor evaporation and heat dissipation is used to improve the effect of forced heat dissipation of the fan, improve its heat exchange efficiency, and reduce refrigeration costs; the water pipe 61 of the spray device 6 is provided with several road branches Water pipes 62, each branch water pipe 62 is provided with sev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com