Method and apparatus for measuring gas forming quantity of calcium carbide by using single calibrating weight method

A technology for calibrating weight and calcium carbide, which is applied in the field of chemical detection, can solve the problems of non-standard gas generation measurement, strict calibration conditions, cumbersome calibration process, etc., and achieve the goal of increasing the amount of sample weighing, simple calibration, and convenient calibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

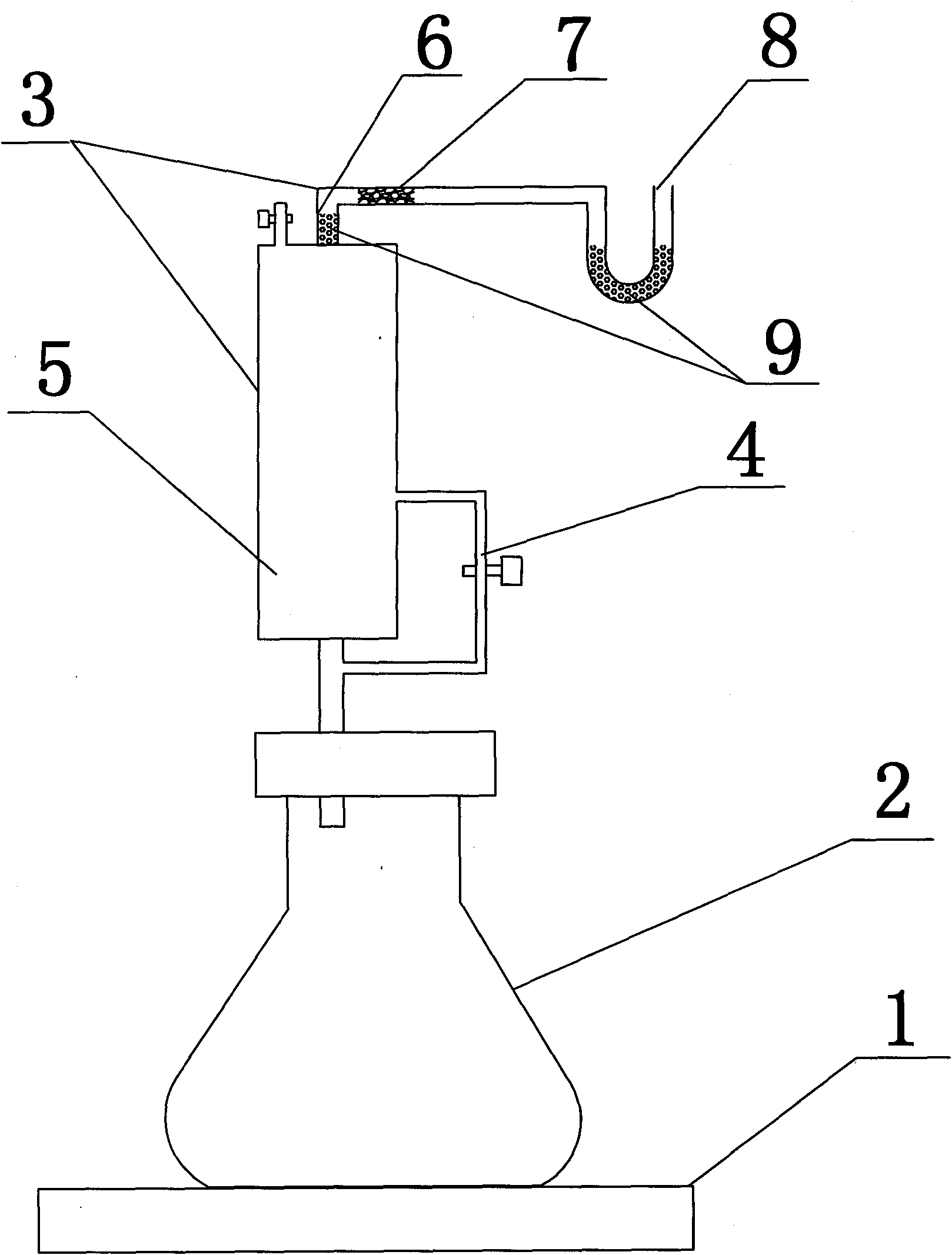

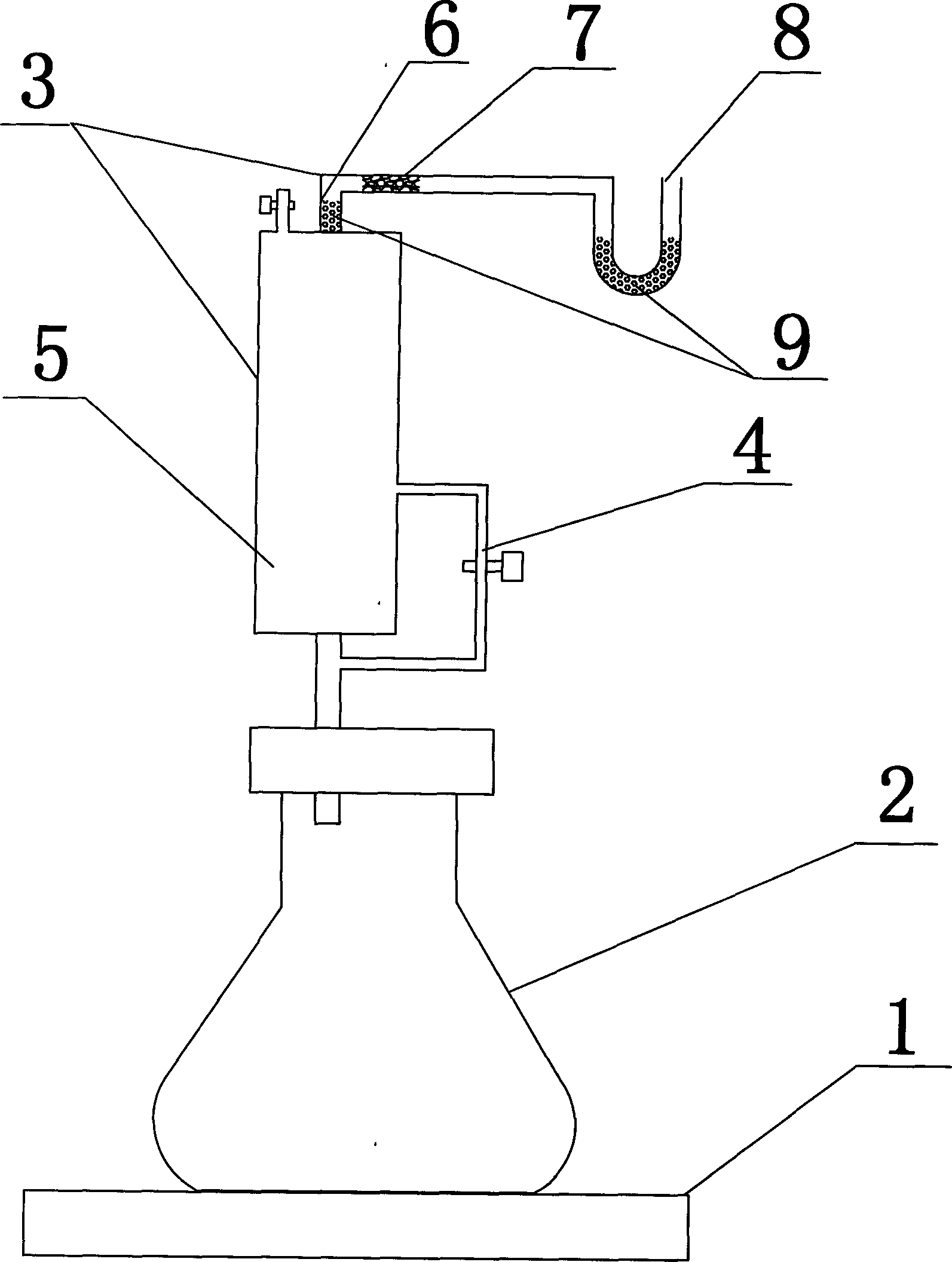

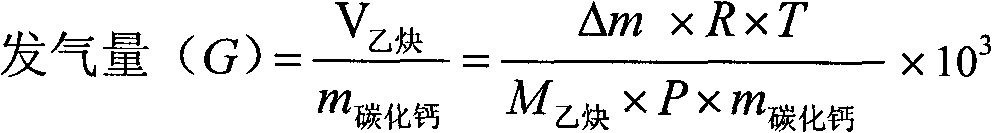

[0043] An instrument device for measuring the gas generation of calcium carbide by a single calibration gravimetric method, such as figure 1 As shown, it includes a weighing device 1, a reactor 2 and a gas purifier 3; the gas inlet of the gas purifier 3 is connected to the gas outlet of the reactor 2, and the reactor 2 and the gas purifier 3 are arranged on the weighing device 1, the weighing device 1 weighs the weight of the reactor 2 and the gas purifier 3. The reactor 2 is a suction filter bottle with a volume of 1000ml. The weighing device 1 is an electronic balance with an accuracy of 0.1 gram. The gas purifier 3 includes a spiral condenser 5, a dust removal structure 7 and a water injection structure 4, the air inlet of the spiral condenser 5 is connected with the gas outlet of the reactor 2, and the gas outlet of the spiral condenser 5 is filled with or without The drying pipe 6 of the calcium chloride hydrate 9 is connected with the air inlet of the dust removal stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com