Rotor position detecting device and method of permanent magnet type synchronous motor

A rotor position detection and synchronous motor technology, which is applied to starting devices, control electromechanical transmission devices, electronic commutators, etc., can solve the problems of long detection time, inability to detect current drop time, inconvenient rotor position detection devices and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0108] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

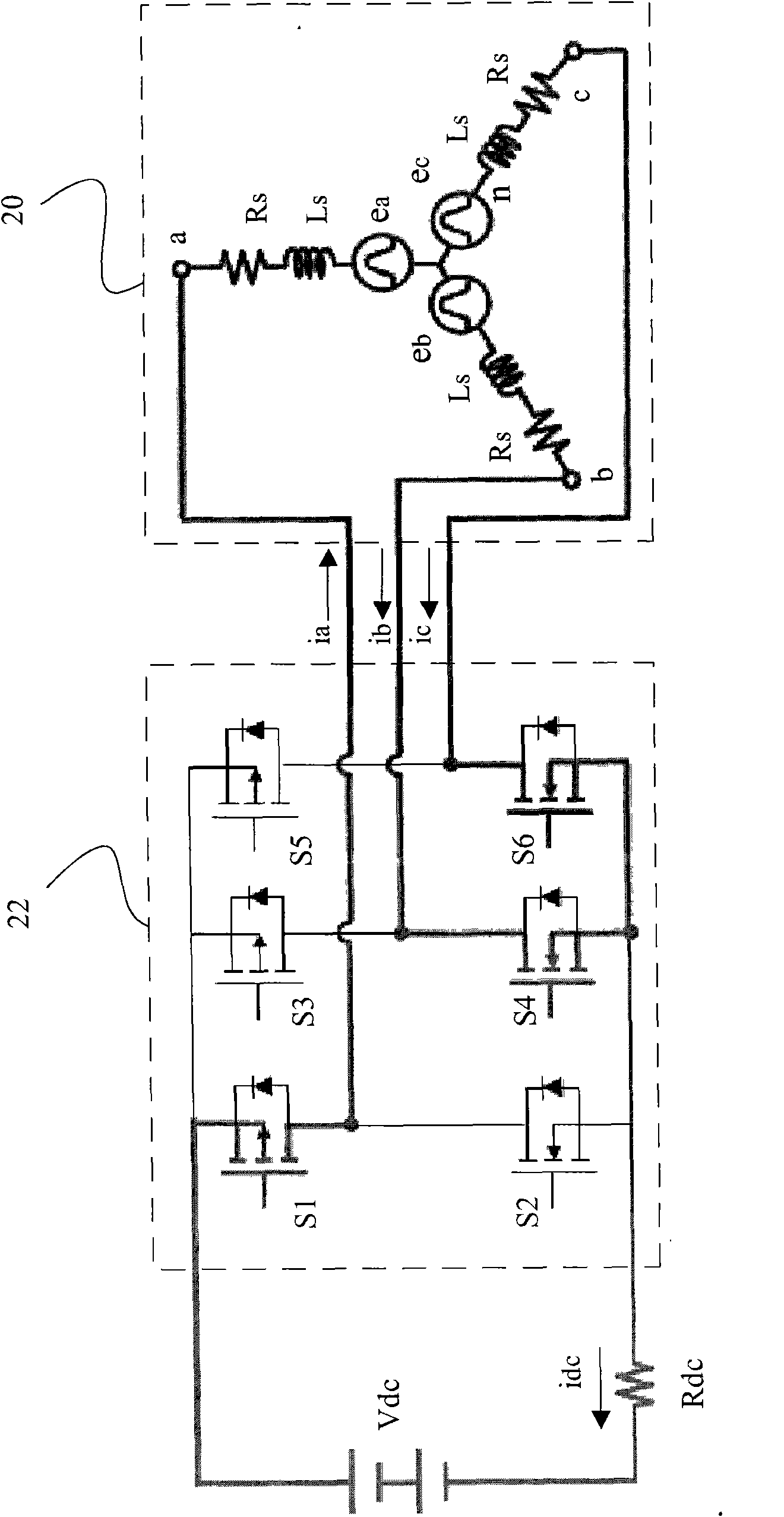

[0109] see now Figure 6 , Figure 6 The first embodiment of the present invention is shown, wherein the driver 34 switches the power switches M1-M6 in the inverter 32 according to the signal PWM_TEST from the detection circuit 46 to apply different voltage vectors to the PMSM 30, and the motor current on the PMSM 30 The related DC link current idc generates the sensing signal Vs through the shunt resistor Rdc, the sensing circuit 36 generates the over-current signal OC and the zero-current signal ZC according to the sensing signal Vs, and the detection circuit 46 generates the over-current signal OC and the zero-current signal ZC according to the over-current signal OC and the zero-current signal ZC Signal PWM_TEST.

[0110] Figure 7 show Figure 6 The signal waveform in . refer to Figure 6 and Figure 7 , when the PMSM 30 is started from the stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com