High-efficiency LED constant current driving circuit

A constant current drive and circuit technology, which is applied in the layout of electric lamp circuits, electric light sources, lighting devices, etc., can solve the problems of large number of LED constant current drive circuit components, complex structure, poor stability, etc., and achieves high integration and small size. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

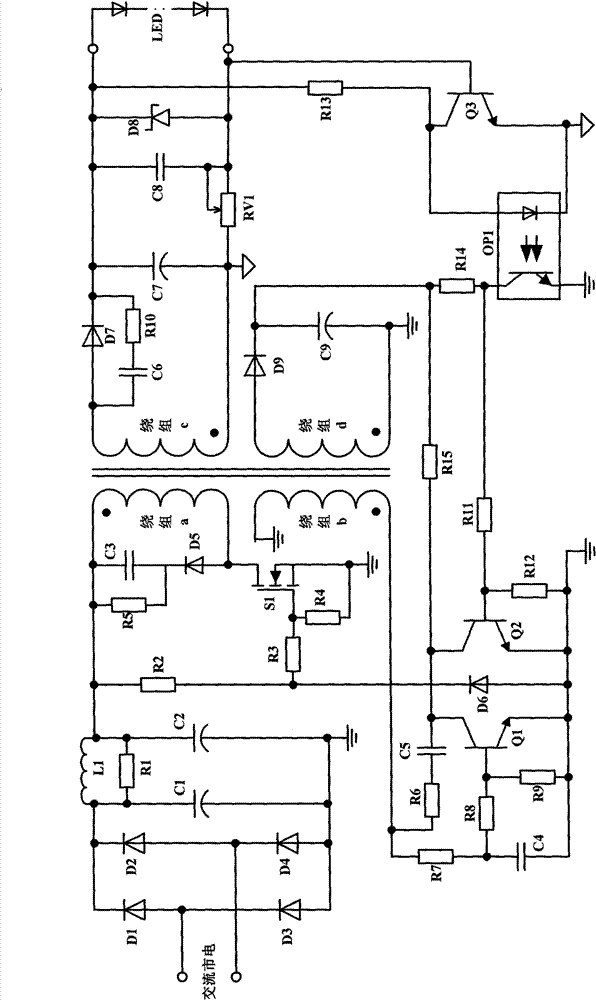

Problems solved by technology

Method used

Image

Examples

Embodiment 1

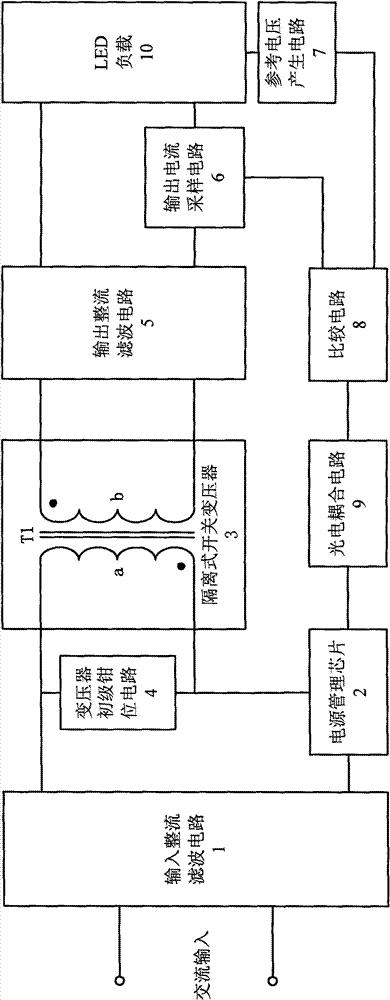

[0033] Embodiment one: as attached figure 2As shown, the LED constant current drive circuit of the present invention includes: input rectification filter circuit 1, switching power supply management chip 2, isolated switching transformer 3, transformer primary clamp circuit 4, output rectification filter circuit 5, output current sampling circuit 6, A reference voltage generation circuit 7 , a comparison circuit 8 , and a photoelectric coupling circuit 9 . The input end of the input rectification filter circuit 1 is connected to the AC mains, and the output end is connected to the primary winding of the isolated switching transformer 3 through the switching power supply management chip 2; the primary clamping circuit 4 of the transformer is connected to the primary winding of the isolated switching transformer 3 The windings are connected in parallel; the input end of the output rectification filter circuit 5 is connected to the secondary winding of the isolated switching tra...

Embodiment 2

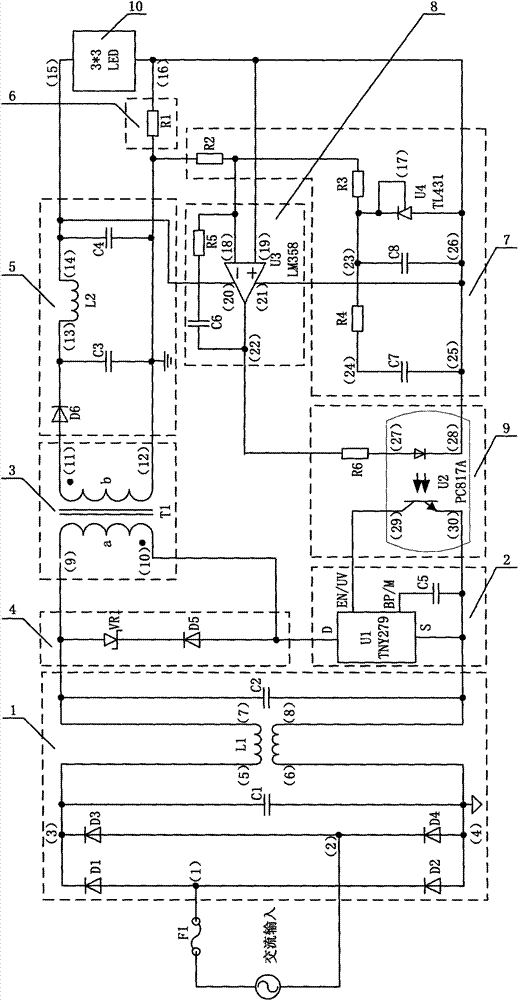

[0035] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows: as attached image 3 As shown, the input rectification filter circuit 1 includes a full-bridge rectifier composed of diodes D1, D2, D3, D4, capacitors C1, C2, common mode inductor L1, the cathode of the diode D2 is connected to the anode of the diode D1, and the diode D4 The cathode of the diode is connected to the anode of the diode D3, and the AC input terminals 1 and 2 are connected to the AC mains; the cathodes of the diodes D1 and D3 are connected as the DC high-voltage output terminal 3 after the rectification of the mains; the anodes of the diodes D2 and D4 are connected as the rectifier The rear ground terminal 4; the DC high voltage output terminals 3 and 4 of the rectifier bridge are respectively connected to the two ends of the capacitor C1 and the two input terminals 5 and 6 of the common mode inductor L1, and the two output terminals 7 and 8 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com