Soybean milk maker

A soymilk machine and drive motor technology, applied in milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems of slurry residue, difficult to clean, heavy structural machine head, etc., to speed up heating, increase pulping speed, and save energy. The effect of spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

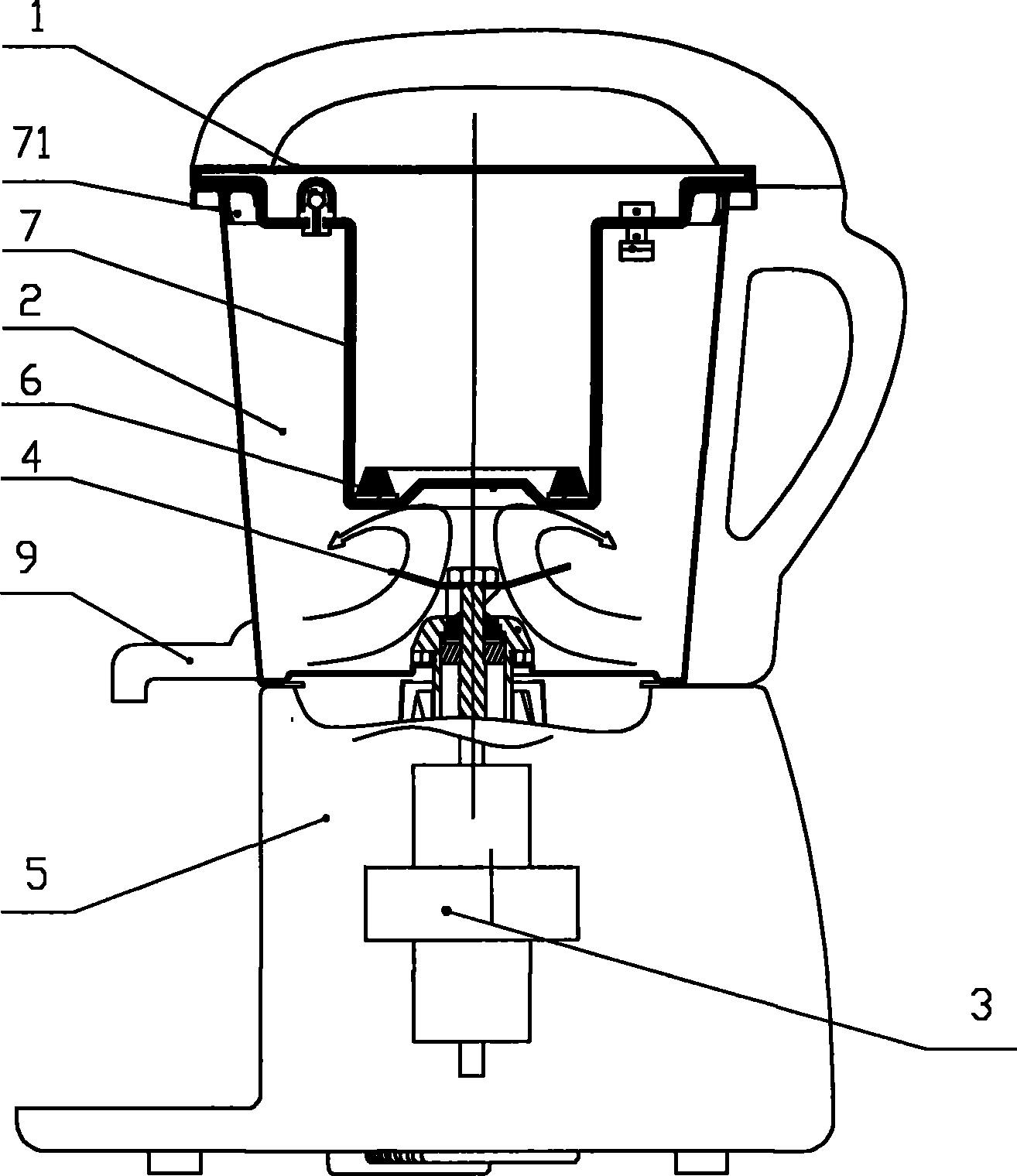

[0047] The soybean milk machine shown in Fig. 1, Fig. 5 and Fig. 6 includes a cup cover 1, a cup body 2, a driving motor 3, a rotating blade 4 and a base 5, wherein the bottom of the cup cover is an inner cover 7, and the inner cover 7 In order to extend from the mouth of the cup to the cup body 2, the bottom surface of the inner cover 7 is a special-shaped surface with a flow guiding effect, the bottom of the inner cover 7 is provided with an electric heating element 6, the motor 3 is arranged in the base 5, and the blade 4 is arranged in the cup body 2 and placed on the inner bottom or below the inner cover 7. The motor shaft of the motor 3 is movably connected with the blade 4 in the cup body through a movable coupling. The blade 4 has a curved surface that makes the slurry roll up and down.

[0048]The electric connection wire of the electric heating element 6 can be electrically connected with the circuit board in the base 5 through the handle. The driving motor 3 and the...

Embodiment 2

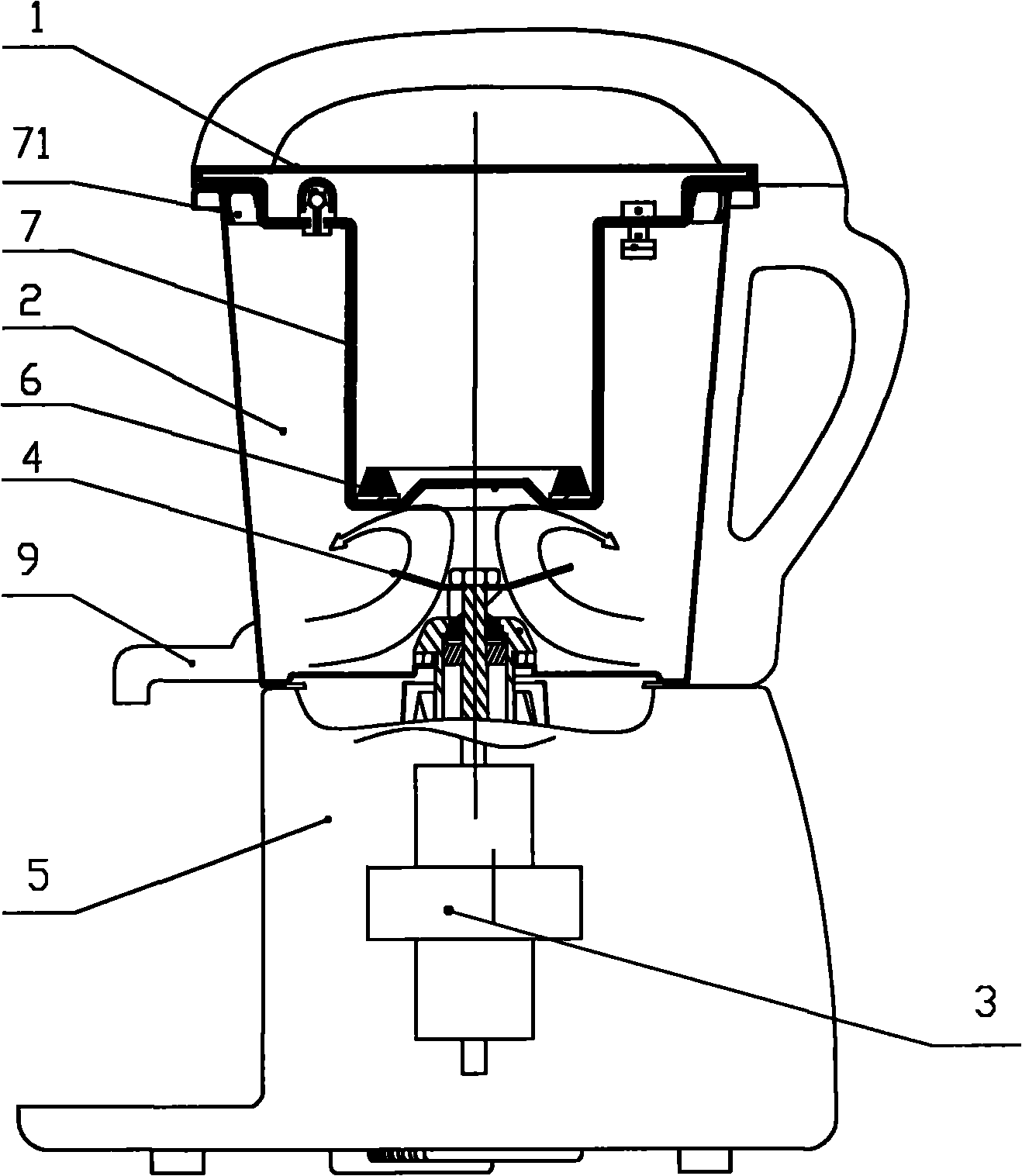

[0057] As shown in Figure 2, different from Embodiment 1, the inner cover 7 in this embodiment can be set as a two-section structure, and the upper end is made of plastic material for heat insulation; the section where the electric heating element 6 is installed is made of metal material, preferably It is made of stainless steel, the electric heating element 6 is arranged on the inner bottom of the stainless steel, and the electric heating element 6 is in contact with the surface of the stainless steel. The inner cover of the plastic material is tightly and fixedly connected with the inner cover of the stainless steel material. The inner cover of the stainless steel section is all set below the minimum water level of the soymilk machine to avoid dry burning and ensure safety during use.

Embodiment 3

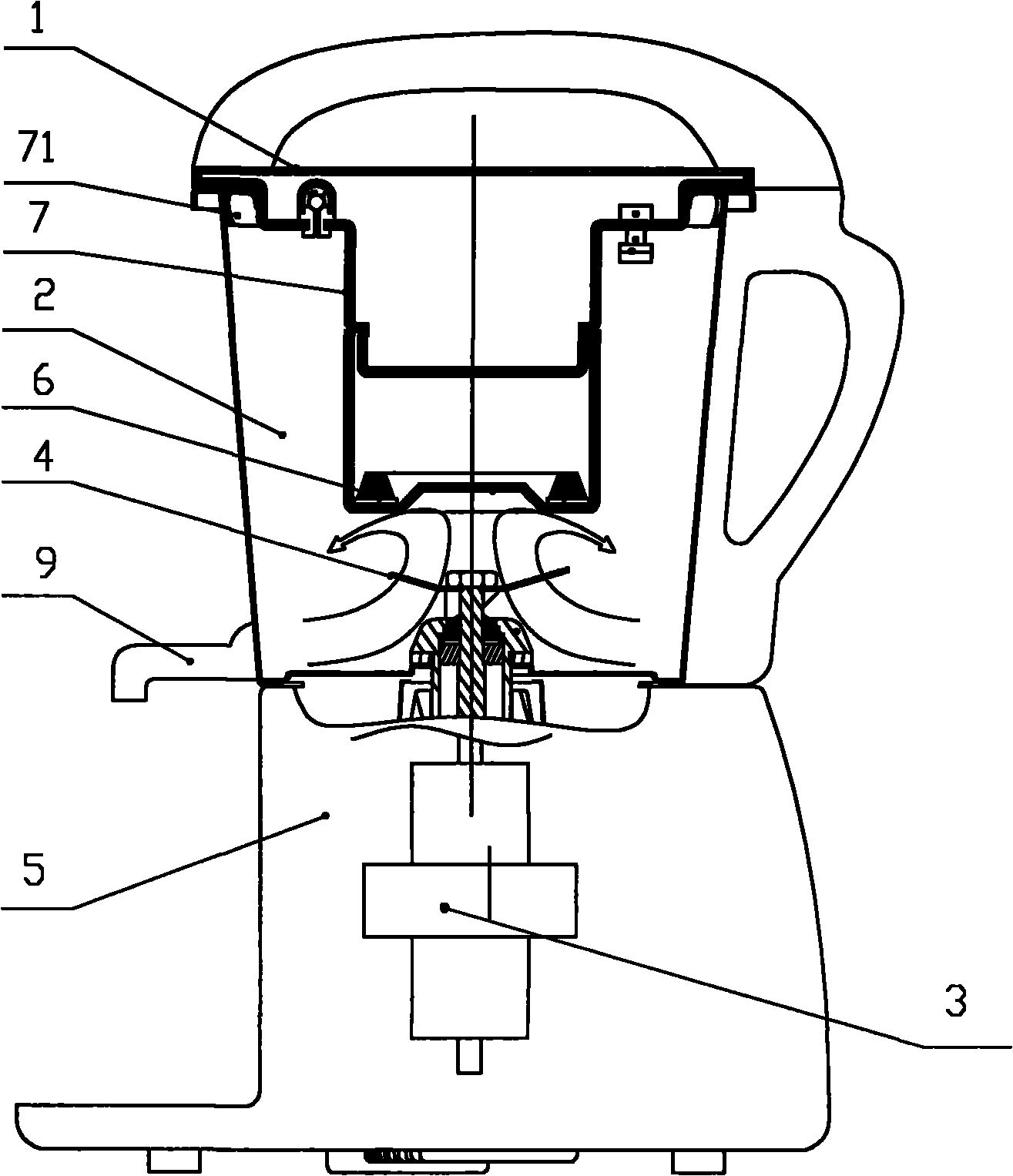

[0059] As shown in Fig. 3, Fig. 7-Fig. 10, the soybean milk machine in this embodiment is provided with a deflector 8. The blade 4 is located at the center of the wind deflector 8 . As shown in FIG. 8 , flow guide grooves 83 are arranged around the flow guide cover; as shown in FIG. 10 , flow guide holes 82 can also be provided in the flow guide cover. The two are mainly aimed at different materials. When it is necessary to turn back and cut fast, the diversion groove 83 is used. When the material reaches the diversion surface body, it returns through the diversion groove 83. When the pulverized matter is easy to cut and there are many, diversion holes 82 are used; when the material reaches the diversion curved surface, the pressured slurry only makes a small part of the diversion through the diversion holes 82, and the other part will stop for a short time at the upper end, so that Prevent too much material under the blade from affecting the effect of crushing and cutting. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com