Carbon-free unburned brick and production method thereof

A technology of non-burning bricks and refractory aggregates, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of affecting the overall stability of use, increased heat loss of ladle, poor anti-stripping performance, etc., and achieves Use stability and slag erosion resistance are improved, the service life is improved, and the compressive strength is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Production of carbon-free unfired bricks of the present invention

[0026] 1. Weighing

[0027] Weigh each material according to the proportioning in Table 1. Among them, brown corundum, α-Al 2 o 3 The source of raw materials for micropowder and sintered magnesia powder is commercially available products, and the saturated magnesium chloride solution is self-prepared.

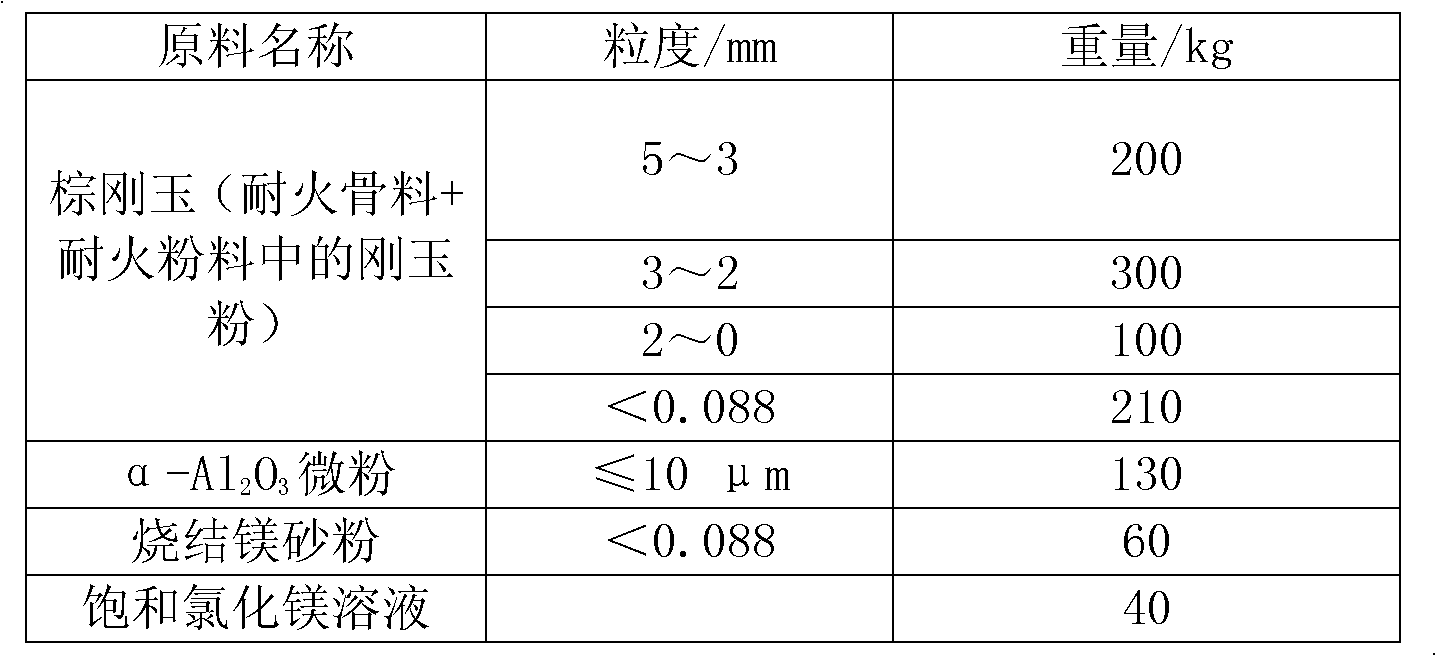

[0028] Table 1 Ratio of each material

[0029]

[0030] 2. Mixing (mixing by rolling method)

[0031] Before production, the residual material in the mud mill should be cleaned up, and there must be no impurities or agglomerates. 600-1200kg of mud for each milling should be ensured to be evenly milled without lumps of raw material. The feeding order of mud milling is: the aggregate is first mixed for 5 minutes, then 1 / 3 of the binder is added and mixed for 5 minutes, and then α-Al 2 o 3 The micropowder, sintered magnesia powder and the remaining 2 / 3 binder are mixed and milled for 8 ...

Embodiment 2

[0036] Example 2 Production of carbon-free unfired bricks of the present invention

[0037] 1. Weighing

[0038] Weigh each material according to the proportioning in Table 2. Among them, white corundum, α-Al 2 o 3 The source of raw materials for micropowder and sintered magnesia powder is commercially available products, and the saturated magnesium chloride solution is self-prepared.

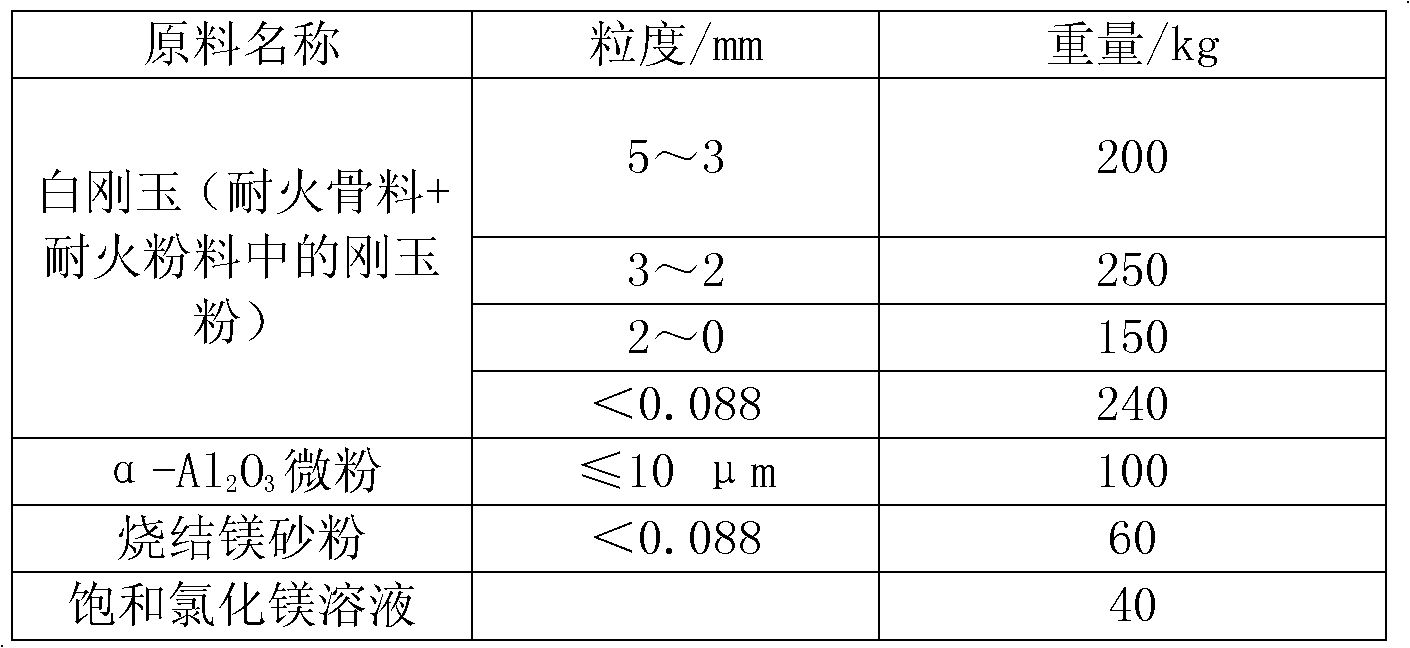

[0039] Table 2 Ratio of each material

[0040]

[0041] 2. Mixing (mixing by rolling method)

[0042] Before production, the residual material in the mud mill should be cleaned up, and there must be no impurities or agglomerates. 600-1200kg of mud for each milling should be ensured to be evenly milled without lumps of raw material. The feeding order of mud milling is: the aggregate is first mixed for 5 minutes, then 1 / 3 of the binder is added and mixed for 5 minutes, and then α-Al 2 o 3 The micropowder, sintered magnesia powder and the remaining 2 / 3 binder are mixed and milled for 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com