Compound insulation board

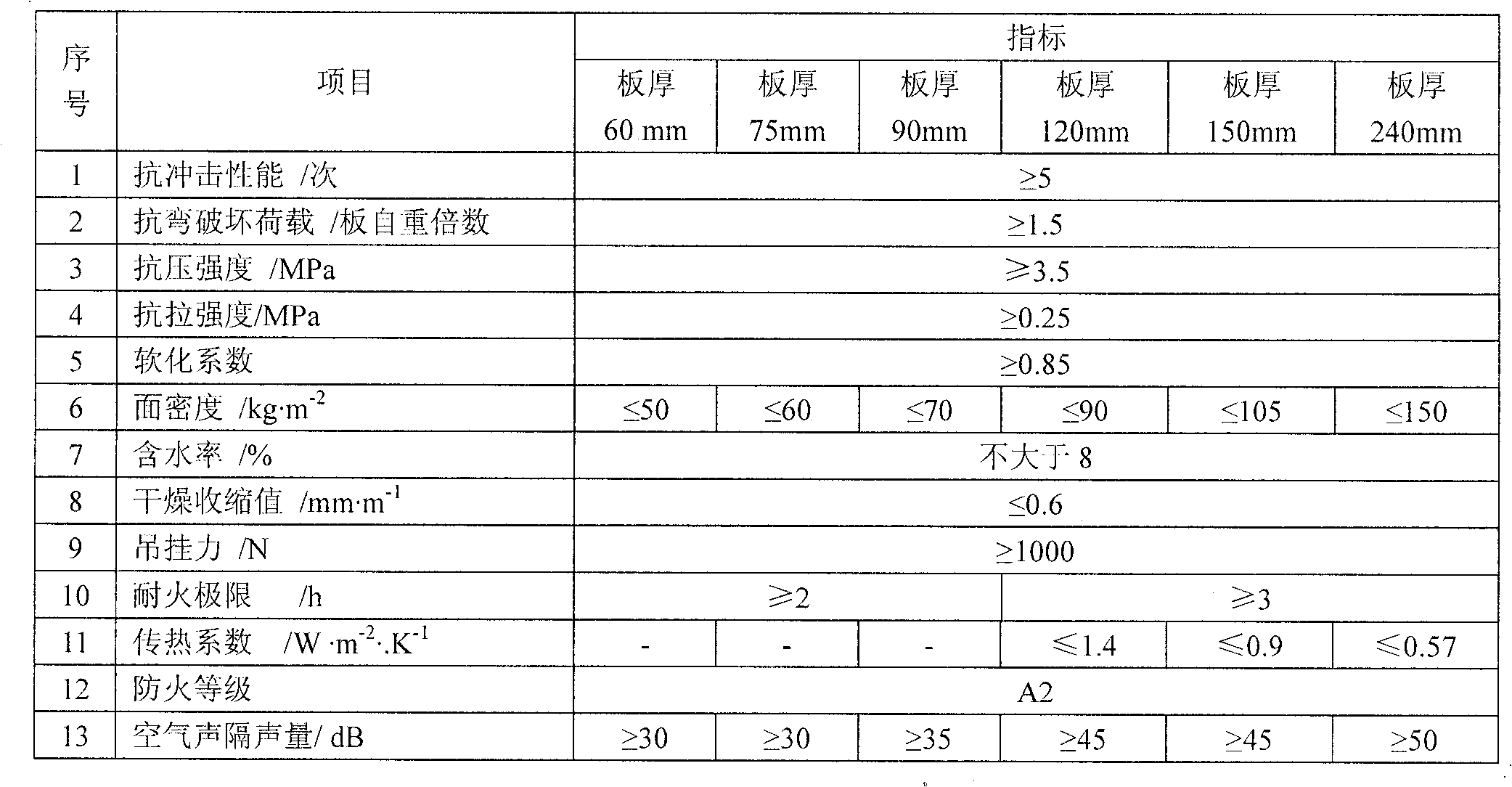

A composite thermal insulation, cement fiber board technology, applied in thermal insulation, synthetic resin layered products, building components, etc., can solve the problem that thermal insulation performance, waterproof and fireproof performance cannot reach construction projects, poor thermal insulation effect, waste of land resources and energy. and other problems, to achieve the effect of outstanding fireproof and waterproof performance, good thermal insulation effect, and energy saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] A composite thermal insulation board, the composite thermal insulation board comprises two layers of cement fiber boards and an intermediate layer arranged between the two layers of cement fiber boards, the intermediate layer is composed of the following components according to their weight percentages:

[0024] Cement 7.5%~8.5%

[0025] Yellow sand 5%~7%

[0026] Fly ash 2.5%~3.5%

[0027] Polystyrene particles 80% to 83%

[0028] Resin powder 1.5%~2.5%,

[0029] The optimum weight proportion of the present invention is:

[0030] Cement 8%

[0031] Yellow sand 6%

[0032] Fly Ash 3%

[0033] Polystyrene pellets 81%

[0034] Resin powder 2%,

[0035] The cement is glazed cement, the yellow sand is yellow medium-coarse sand, and the diameter of the regenerated polystyrene particles is 3 mm to 5 mm.

[0036] After mixing 80kg of cement, 60kg of yellow sand, 30kg of fly ash, 81kg of polystyrene particles, and 20kg of resin powder, the composite insulation board is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap