Noise reducing structure of gasoline engine intake system

A gasoline engine and air intake system technology, applied in the direction of engine components, machines/engines, charging systems, etc., can solve problems such as unsatisfactory effects, and achieve the effect of simple structure, small performance impact, and strong noise reduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

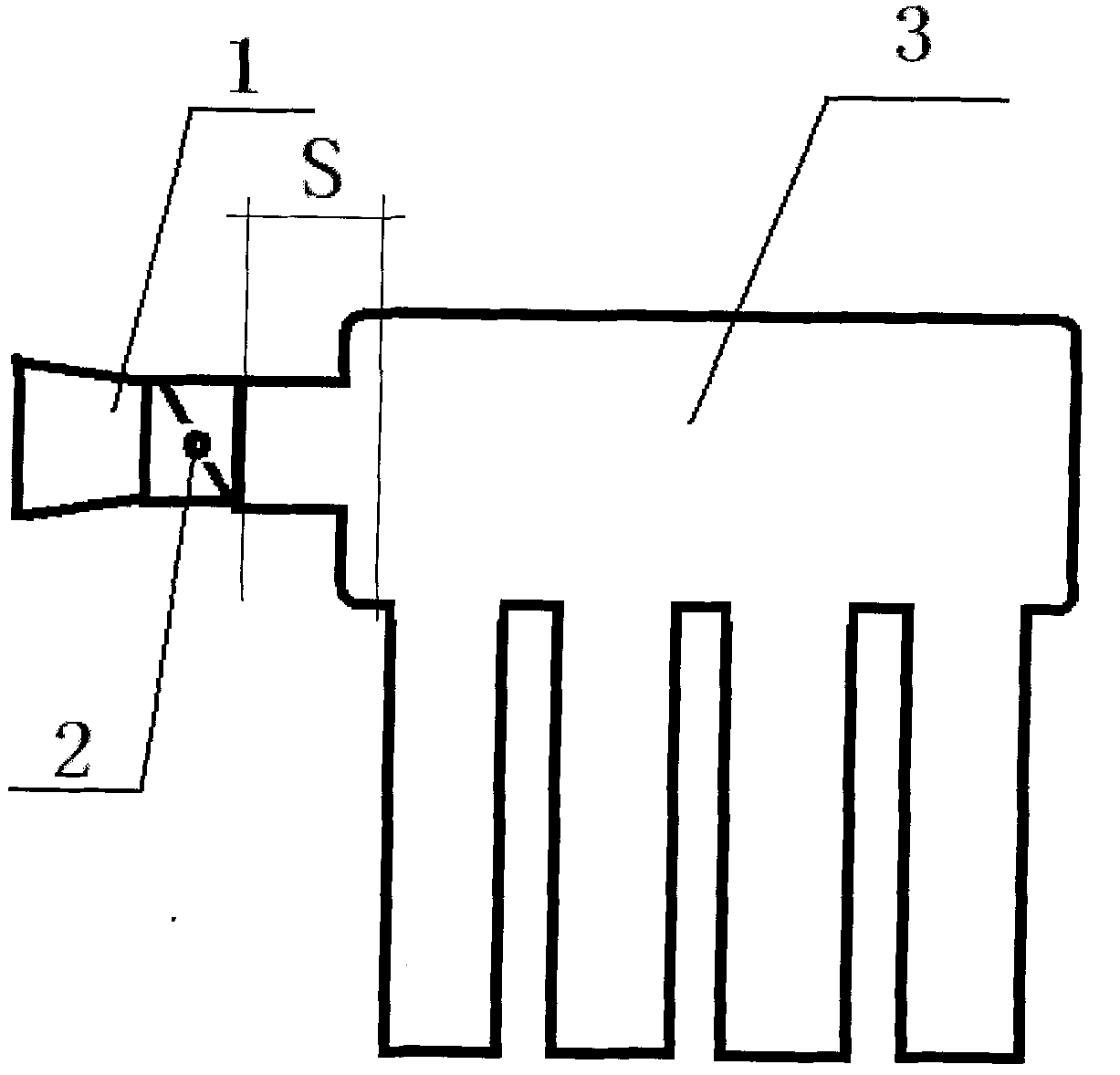

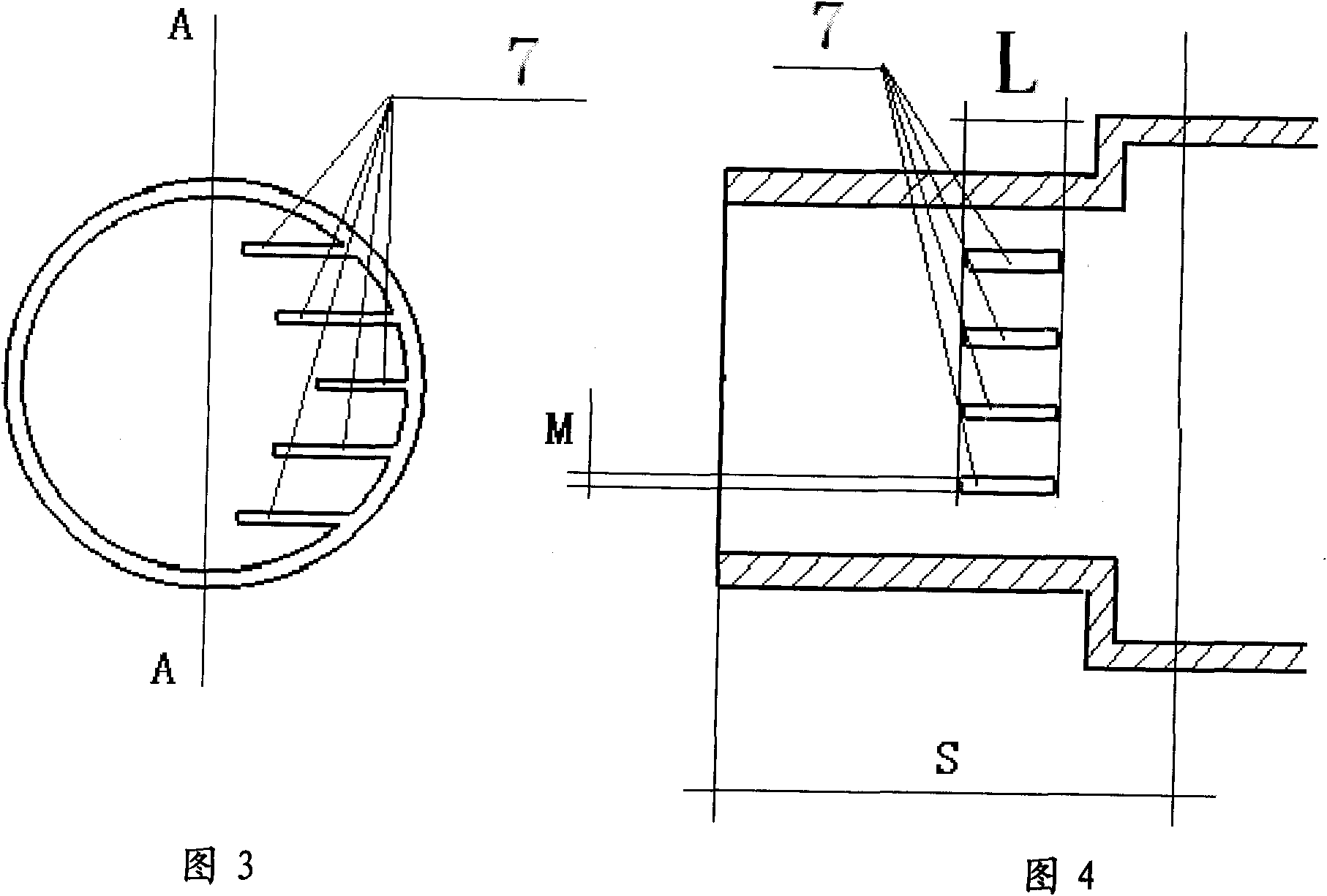

[0027] Embodiment one: see figure 1 , image 3 , Figure 4 The noise reduction structure of a gasoline engine air intake system shown in the figure has a main body of a diversion structure 7, which is a parallel half-tooth type, and is arranged behind the valve plate 2 of the gasoline engine intake system to the intake port. In the S area before the interface with the resonant cavity, the flow guide structure is formed separately, and it is set in the S area from behind the valve plate 2 of the gasoline engine intake system to before the interface between the air intake channel and the resonant cavity, and welded with the resonant cavity. Gas manifold 3 is fixedly connected.

Embodiment 2

[0028] Embodiment two: see figure 1 , Figure 5 , Figure 6 The noise reduction structure of a gasoline engine air intake system shown has another flow guide structure 7 as its main body. The flow guide structure is an independent plate type, and is integral with the intake manifold 3, and is formed by injection molding or casting.

Embodiment 3

[0029] Embodiment three: see figure 1 , Figure 7 The noise reduction structure of a gasoline engine air intake system shown in the figure has a main body of a flow guide structure 7, which is a full mesh structure, formed separately, and assembled on the throttle body after welding or integrating with a sealing ring 1 and intake manifold 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com