In-use lubricating oil quality rapid testing method

A detection method and lubricating oil technology, applied in the direction of measuring device, color/spectral characteristic measurement, material analysis through optical means, etc., to achieve the effect of simple operation, low requirements for operators, and improved monitoring ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

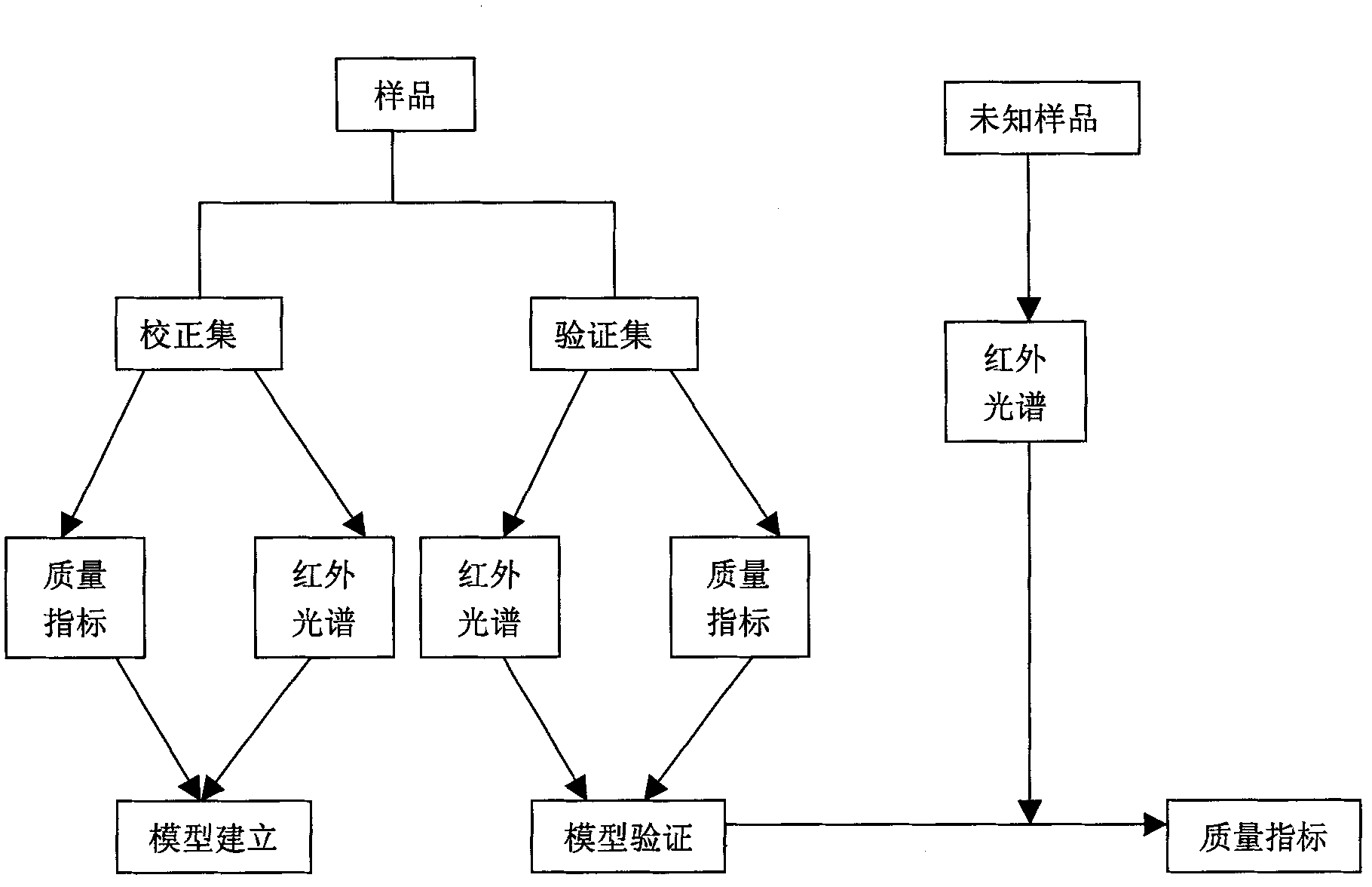

Method used

Image

Examples

example 1

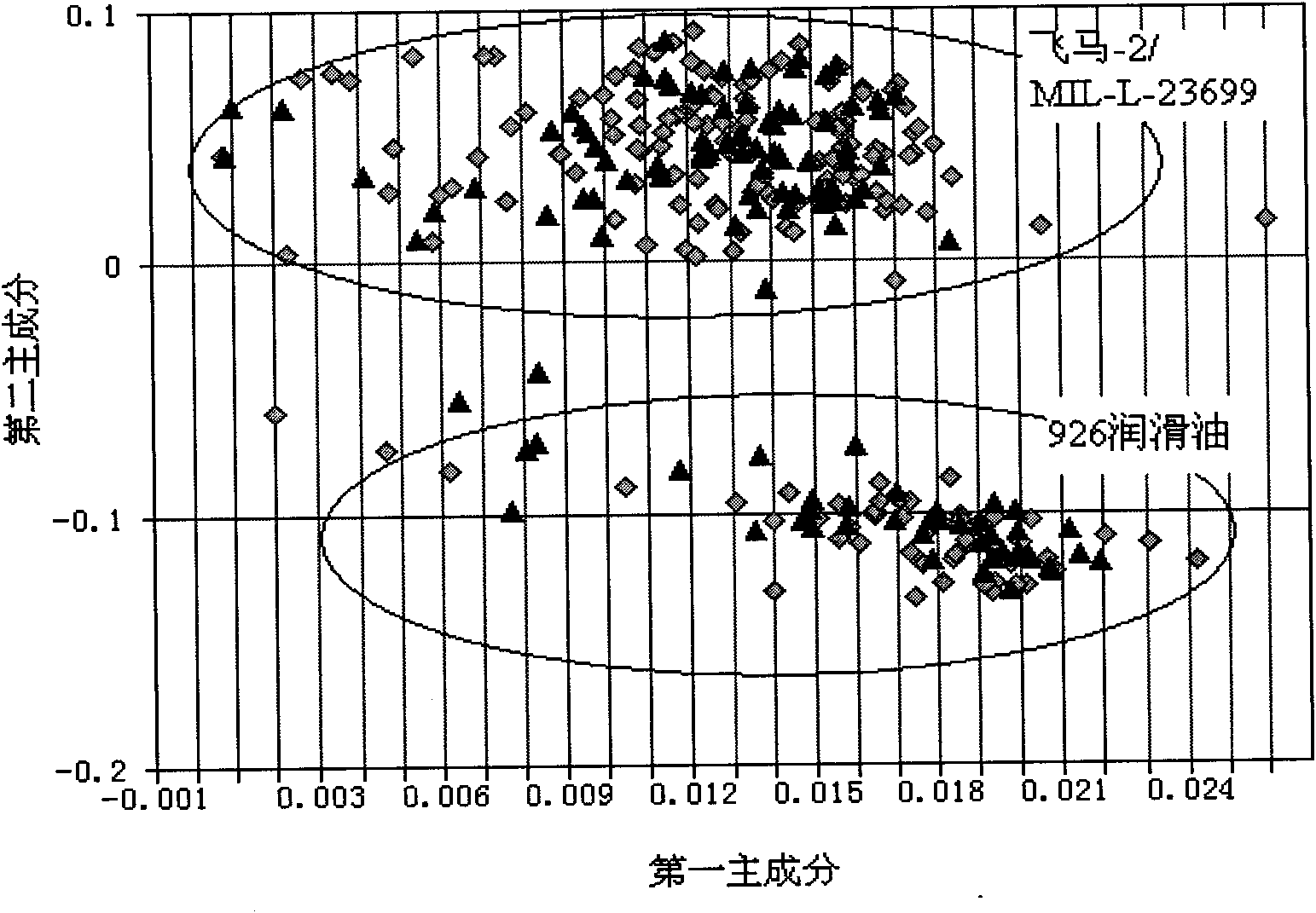

[0054] Example 1: Determination of the quality of aviation engine oil in use by ATR method.

[0055] 1) Sample collection in the oil training set

[0056] 426 in-use samples of aero-engine oil were collected, including 99 samples of No. 926 aero-engine oil and 327 samples of No. 926 aero-engine oil.

[0057] 2) Determination of infrared spectrum of lubricating oil

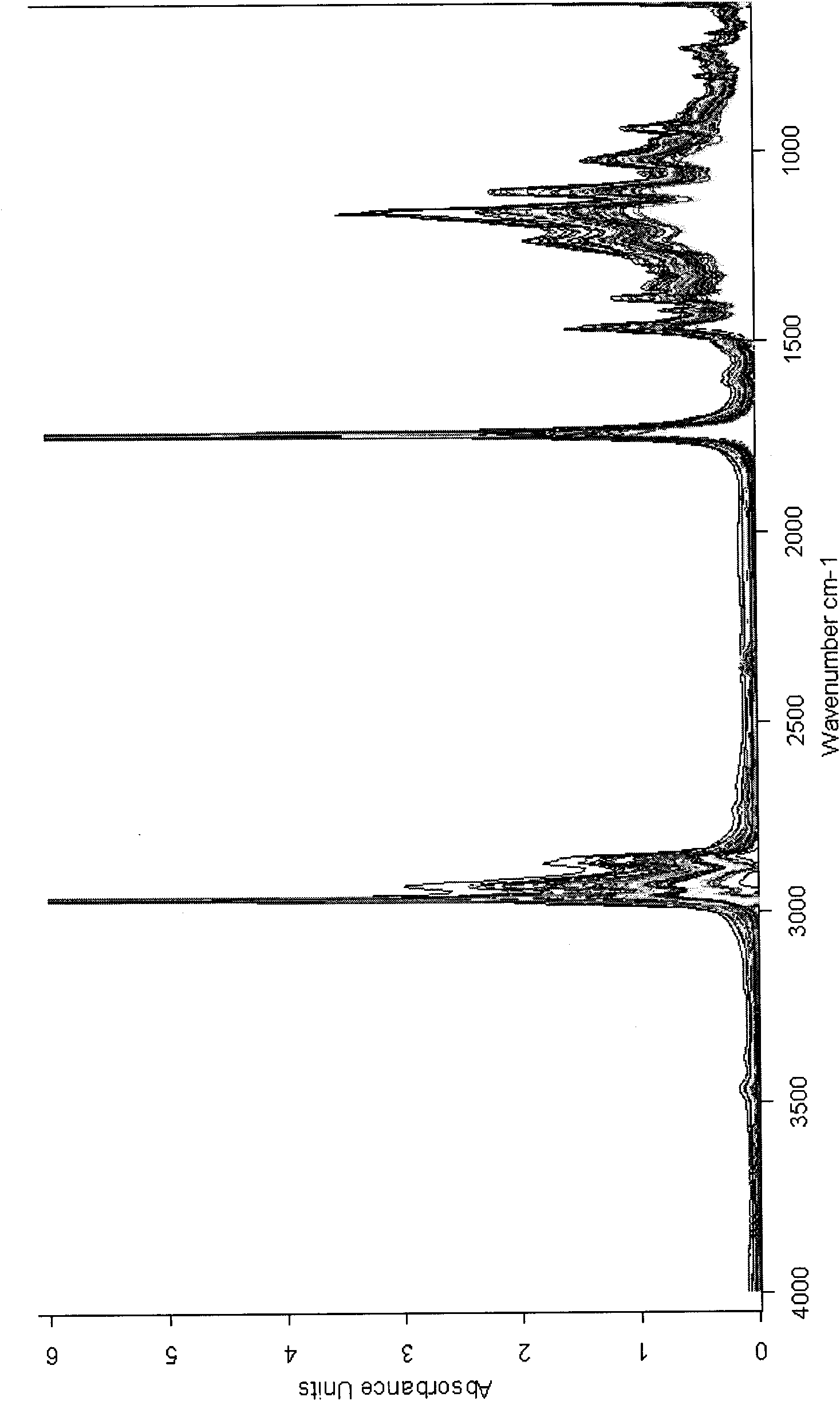

[0058] Use Tensor 27 mid-infrared spectrometer to measure the infrared spectrum of the above lubricating oil, spectral range: 550-4100cm -1 . ATR reflection sample cell, reflection 10 times, please see the mid-infrared spectrum figure 1 .

[0059] 3) The quality index of the lubricating oil sample was measured by a standard method, and the measurement results are shown in Table 2.

[0060] Table 1 lists the units, standard methods, reproducibility requirements and repeatability requirements of each quality index. Due to the huge amount of data, Table 2 only lists the maximum value, minimum value and average v...

example 2

[0075] Example 2: Determination of vehicle engine oil in-use oil quality index by ATR method

[0076] 1) Collected in the training set of oil samples

[0077] Collect 88 vehicle engine oil samples, including 29 samples of CD 10W / 40 engine oil and 59 samples of CD15W / 40 engine oil.

[0078] 2) Determination of infrared spectrum of lubricating oil

[0079] Use Tensor 27 mid-infrared spectrometer to measure the infrared spectrum of the above lubricating oil, spectral range: 550-4100cm -1 . ATR sample cell, reflection 10 times.

[0080] 3) Adopt the method in Table 1 in Example 1 to measure the quality index of the lubricating oil sample. The measurement results are shown in Table 6. Because of the huge data, Table 6 only lists the maximum value, minimum value and average value of each quality index of the training set sample .

[0081] Table 6

[0082]

Sticky at 100°C

degrees, mm 2 / s

TBN,

mgKOH / g

TAN,

mgKOH / g

℃

...

example 3

[0092] Example 3: Determination of vehicle gear oil in-use oil quality index by ATR method

[0093] 1) Collect in-use oil samples

[0094] Collect 97 samples of vehicle gear oil in use, including 29 samples of GL-580W / 90 gear oil, 38 samples of No. 18 hyperbolic gear oil, and 30 samples of GL-585W / 90 gear oil.

[0095] 2) Determination of infrared spectrum of lubricating oil

[0096] Use Tensor 27 mid-infrared spectrometer to measure the infrared spectrum of the above lubricating oil, spectral range: 550-4100cm -1 . ATR sample cell, reflection 10 times.

[0097] 3) Using the method in Table 1 in Example 1 to measure the quality indicators of the lubricating oil samples, Table 10 lists the maximum, minimum and average values of each quality indicator of the training set samples.

[0098] Table 10

[0099]

Quality Index

Viscosity at 100°C

, mm 2 / s

TBN,

mgKOH / g

TAN,

mgKOH / g

pour point

,℃

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com