Preparation method of quadrivalent uranium-cerium-oxygen solid solution

A solid solution and solution technology, which is applied in the field of preparing tetravalent uranium-cerium-oxygen, can solve the problem that it is difficult to ensure the uniformity of U-Pu-O solid solution, and achieve the effect of ensuring safety and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

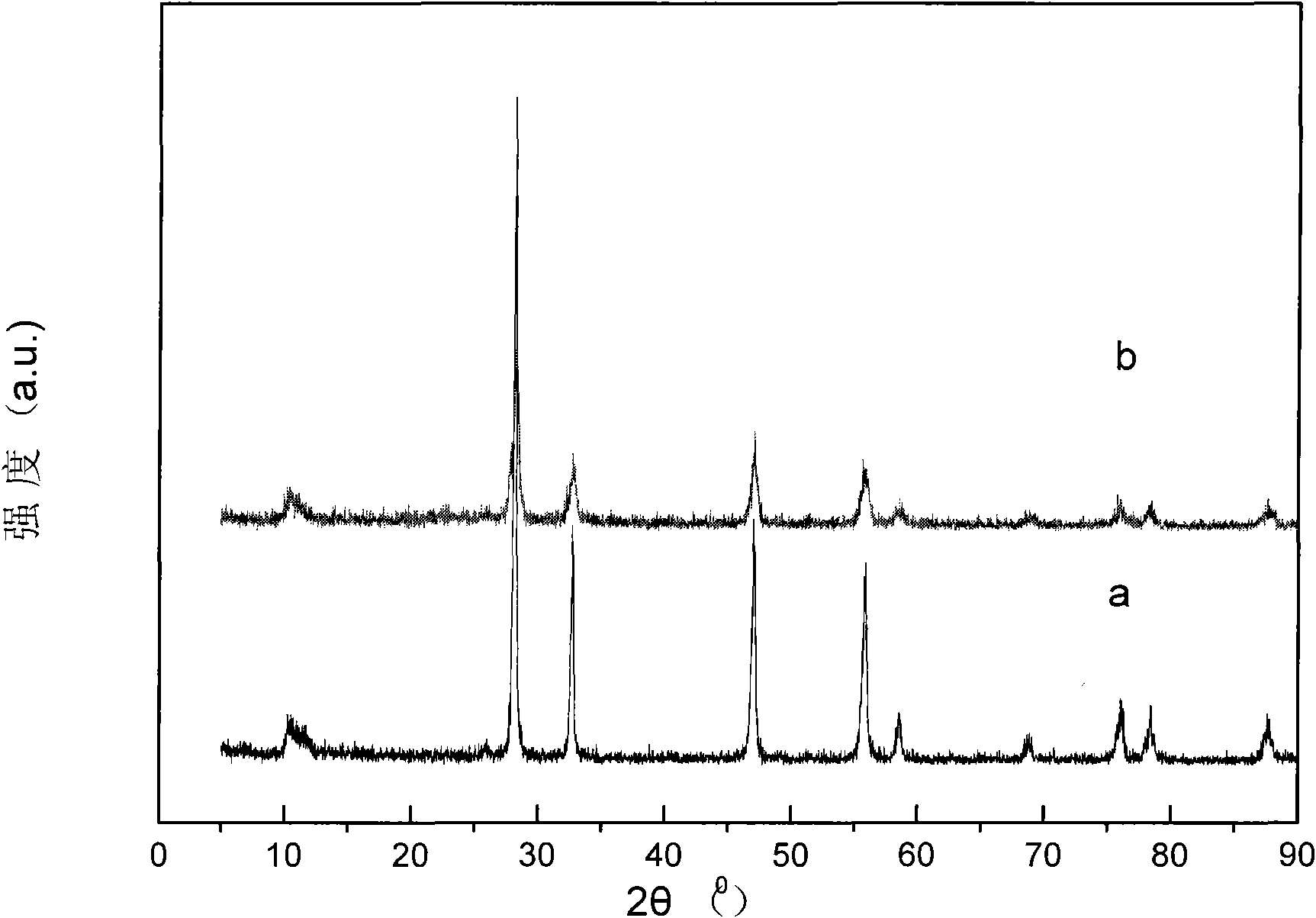

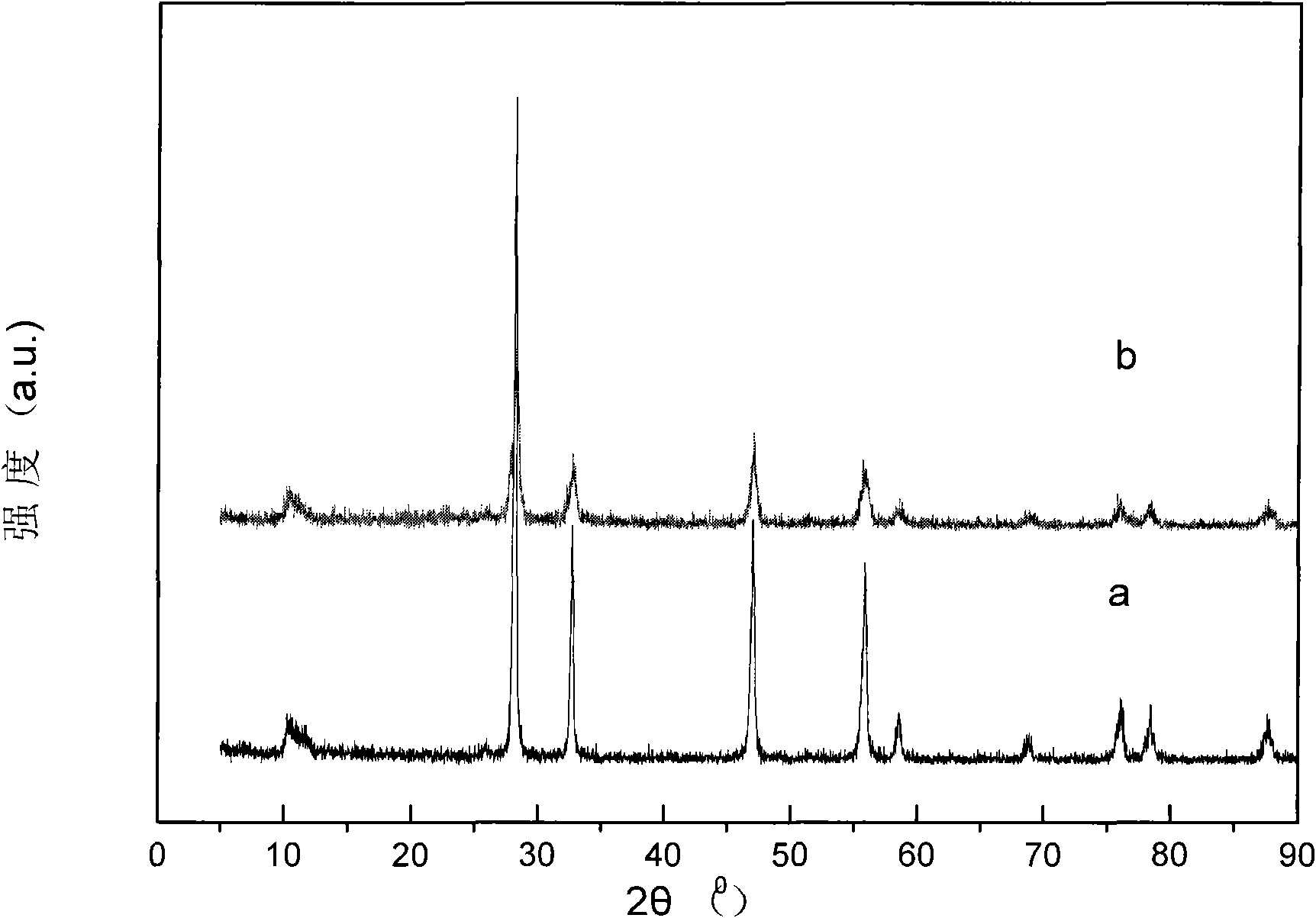

Embodiment 1

[0023] Dissolve uranium oxide with 6mol / L nitric acid, configure 65g / L uranyl nitrate solution, dissolve cerous nitrate and oxalic acid respectively with deionized water, prepare 0.5mol / L cerous nitrate solution and 0.5mol / L oxalic acid solution, and 65g / L uranyl nitrate solution is placed in the cathode chamber of the electrolytic cell, 2.5mol / L nitric acid is added into the anode chamber, the titanium mesh is used as the cathode, and the platinum-plated titanium sheet is used as the anode. -2 . Carry out electrolysis at normal temperature, after 15 hours, get uranium nitrate solution at the cathode, draw out the cathode chamber electrolyte; press UO 2 : CeO 2 The weight ratio is calculated as 90:10, add 0.5mol / L cerous nitrate solution, mix well, slowly add into 0.5mol / L oxalic acid solution, filter the obtained precipitate and wash with deionized water, dry naturally, place in In the tube furnace, the temperature was raised to 1223K, and kept for 4 hours, then cooled natu...

Embodiment 2

[0025] Dissolve uranium oxide with 6mol / L nitric acid, configure 180g / L uranyl nitrate solution, dissolve cerous nitrate and oxalic acid respectively with deionized water, and prepare 0.5mol / L cerous nitrate solution and 0.5mol / L oxalic acid solution; 180g / L uranyl nitrate solution is placed in the cathode chamber of the electrolytic cell, 2.5mol / L nitric acid is added to the anode chamber, the titanium mesh is used as the cathode, and the platinum-plated titanium sheet is used as the anode. -2 . Perform electrolysis at normal temperature, after 8 hours, get uranium nitrate solution at the cathode, press UO 2 : CeO 2 Calculated at a weight ratio of 95:5, add 0.5 mol / L cerous nitrate solution, mix well, slowly add to 0.5 mol / L oxalic acid solution, filter the resulting precipitate and wash with deionized water, dry naturally, and place In the tube furnace, the temperature was raised to 1473K, and kept for 2 hours, then cooled naturally, and finally the oxide was obtained. fi...

Embodiment 3

[0027] Dissolve uranium oxide with 6mol / L nitric acid, configure 150g / L uranyl nitrate solution, dissolve cerous nitrate and oxalic acid respectively with deionized water, and prepare 0.5mol / L cerous nitrate solution and 0.5mol / L oxalic acid solution; 150g / L uranyl nitrate solution is placed in the cathode chamber of the electrolytic cell, 3mol / L nitric acid is added into the anode chamber, the titanium mesh is used as the cathode, the platinum-plated titanium sheet is used as the anode, the area ratio of yin and yang is 2, and the current density is 20mA.cm -2 . Carry out electrolysis at normal temperature, after 30 hours, the cathode will get uranium nitrate solution, draw out the cathode chamber electrolyte, press UO 2 : CeO 2 Calculated at a weight ratio of 99:1, add 0.5 mol / L cerous nitrate solution, mix well, slowly add to 0.5 mol / L oxalic acid solution, filter the resulting precipitate and wash with deionized water, dry naturally, place in In the tube furnace, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com