Seedling raising device with direct use and making and use methods thereof

A seedling raising device and direct technology, applied in the fields of application, cultivation, agriculture, etc., can solve the problems that the seeder does not match the specifications of the floating plate, the standard is difficult to quantify, and the operation process is complicated, so as to improve the planting efficiency, simplify the operation, simplify the The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

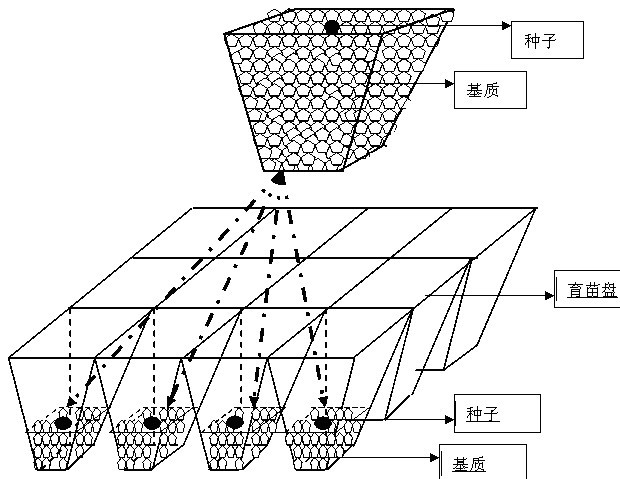

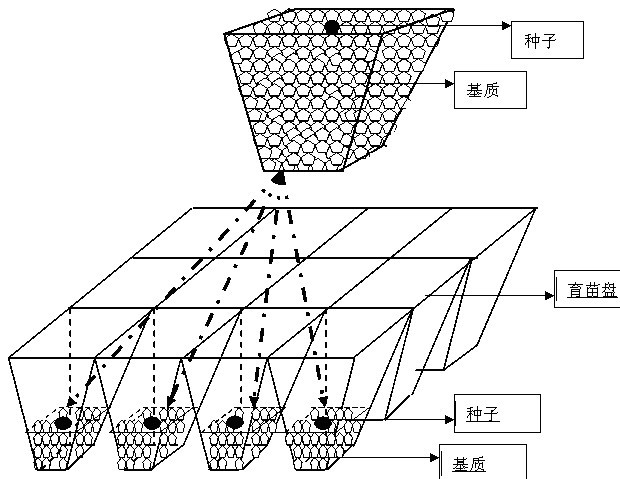

Embodiment 1

[0019] Embodiment 1: get 1kg cross-linked polymer, the mixture of air-dried vermicompost and peat of 10kg arbitrary proportioning, and the mixture of vermicompost and peat is ground into the particle below 20 orders, cross-linked polymer and vermicompost and peat Mix the mixture evenly to prepare the seedling-raising substrate, and take 1g of each portion, put 1 coated flue-cured tobacco seed in every 1g of the seedling-raising substrate, and press it into a block shape matching the hole shape of the disposable seedling-raising tray with a briquetting machine. This product can be completed by squeezing the blocky seed-containing seedling substrate into the hole of the disposable seedling tray. When using it, put the disposable seedling tray containing seeds and seedling substrate into the seedling pond. Pay attention It is desirable that the distance between the seed and the upper surface of the seedling raising substrate is 1-3 mm, and the cross-linked polymer used is a cross-...

Embodiment 2

[0020] Embodiment 2: get 1kg cross-linked polymer, the mixture of air-dried vermicompost, peat, rapeseed cake or peat of 50kg arbitrary proportioning constitutes organic material, and organic material is pulverized into the particle below 20 orders, cross-linked polymer Mix evenly with organic materials to prepare seedling-growing substrates, and take 50g of each part, put 2 flue-cured tobacco seeds in every 50g of seedling-raising substrates, and use a briquetting machine to press into blocks that match the shape of the floating plate. It is a cube, a cuboid, a sphere, an ellipsoid, a cone or a trapezoid, and then squeeze the seed-containing seedling substrate extruded into a block into the hole of the disposable seedling tray to complete this product. The seedling raising devices can be arranged in order in the floating tray and placed in the seedling pond. It should be noted that the distance between the seeds and the upper surface of the seedling raising substrate is 1-3mm,...

Embodiment 3

[0021] Embodiment 3: Take 1 kg of cross-linked polymer 24 kg of air-dried vermicompost, peat, rapeseed cake, peat, cow dung or pig manure mixture or one of them to form an organic material, and grind the organic material into particles below 20 mesh , uniformly mix the cross-linked polymer and organic materials to prepare the seedling-growing matrix, and take 25g of each part, put 1 coated flue-cured tobacco seed in every 25g of the seedling-growing matrix, and use a briquetting machine to press it into a shape similar to that of the floating plate. Matching block, its shape can be cube, cuboid, sphere, ellipsoid, cone or trapezoid, and then extrude the seed-containing seedling substrate extruded into the block into the hole of the disposable seedling tray to complete When using this product, you can arrange the seedling raising devices in sequence in the floating tray and put them into the seedling pond. It should be noted that the distance between the seeds and the upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com